Anodizing

Anodizing is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts.

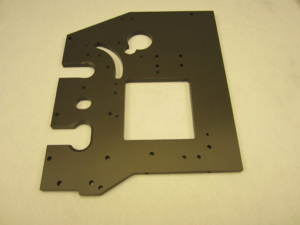

Anodizing increases corrosion resistance and wear resistance, and provides better adhesion for paint primers and glues than does bare metal. Anodic films can also be used for some cosmetic effects with thinner transparent coatings or thicker porous coatings that can absorb dyes.

The anodizing process changes the microscopic texture of the surface and changes the crystal structure of the metal near the surface. Thick coatings are porous, so a sealing process is often needed to achieve corrosion resistance.

Anodized aluminum surfaces, for example, are harder than aluminum, but can have good wear resistance that can be improved with increasing thickness or by applying suitable sealing substances. Anodic films are generally much stronger and more adherent than most types of paint and metal plating, but also more brittle. This makes them less likely to crack and peel from aging and wear, but more susceptible to cracking from thermal stress.

Valence offers every variety of anodizing, including but not limited to:

Type I Anodize

- Boric Anodize – Boric-Sulfuric Acid Anodize (BSAA) is an alternative to chromic acid anodize (CAA), that builds a thin-film anodic coating and provides corrosion protection and a mechanical bond. This is a

non –chromated , environmentally friendly solution. - Tartaric Anodize – Tartaric-Sulfuric Anodize (TSA) is an alternative to chromic acid anodize (CAA), that builds a thin-film anodic coating and provides corrosion protection and a mechanical bond. This is a

non chromated - Chromic Anodize – Chromic Acid Anodize (CAA) creates the thinnest anodic

coating, while providing the same corrosion resistance as other types of anodization, such as boric or sulfuric.

Type II

- Sulfuric Anodize – Sulfuric Acid Anodize (SAA) is used when hardness and abrasion resistance is required on a

part, and creates a surface that is harder than traditional chromic anodizing.

Type III

- Hard Anodize – Hardcoat anodize is created is a sulfuric acid bath, but results in a much thicker surface anode coating than traditional sulfuric acid anodizing.

Phosphoric Acid Anodize

- Phosphoric Acid Anodize – Phosphoric Acid Anodize (PAA) is most commonly used in bonding applications, as it provides a superior porous surface for bonding to composites.

Please contact us with any questions about our anodizing process or request a quote today.

What Is Anodizing?

Anodizing is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. It is called anodizing because what is being treated forms the ‘anode electrode’ which is a type of electrical conductor, or electrode, of a polarized electrical device that a conventional current enters through.

This is done to increase resistance to traditional wear and tear as well as corrosion. It also provides better adhesion for paint primers and glues than bare metal does. Interestingly enough, anodic films (a type of coating over aluminum or other substrates) are used for a cosmetic effect over materials like aluminum.

Metals like aluminum, magnesium, titanium, etc., have found applications in various industries ranging from automotive to aerospace, to electronics, etc., because of their desirable properties.

How Does It Work?

This process works by immersing a metal substrate into an acid electrolyte bath which then – through electrifying the substrate and solution – into a piece that is durable thanks to the anodic oxide finish. Below is a breakdown of the steps involved:

Anodizing Process Steps

The anodizing process requires a few steps including:

Pre-Treatment

Before you anodize a part, you have to prepare its surface through mechanical and chemical means. To give your part the desired aesthetic, polish or bead blast the surface first. While brushing will give your part a brushed appearance, bead blasting will give it a natural matte finish.

The chemicals you employ before anodizing will affect how glossy your product turns out. For instance, etching will give your item a satin finish that is smooth. You should choose bright dipping or chemical polishing for a glossy finish.

Rinsing

Remove contaminants, such as machining waste like lubricants and coolant, from the item by rinsing it in deionized water and other solvents. To remove the metal’s surface layer, submerge the washed components in a solution of sodium hydroxide (NaOH) and nitric acid (HNO3). This procedure is not necessarily required if the item has already been mechanically treated.

To stop an anodizing surface from forming in certain sections of a part, you can mask such areas.

Etching (Chemical Milling)

Sodium hydroxide solution is often used for alkaline etching.It gives the metal’s surface a light-gray satin gloss (through a diffuse reflection of the incident light). This pre-treatment method is used for the vast bulk of jobs.

The amount of sodium hydroxide solution present, the temperature, and the number of aluminum ions discharged into the solution all affect how quickly an object etches. The solution becomes ineffective when aluminum ions are present in large proportions. Other ions may be present, some of which may be an alloy component, interfering with the process and leaving flaws on the work’s surface.

By using etching solutions that inhibit the action of the released Al3+ and other metal ions, the issue of ion contamination is solved. These solutions’ ingredients are proprietary to the businesses that create them, although they typically include sequestering agents that contain complex metal ions. These solutions don’t have an endless capacity to do this, but because the etched work “carries over” the solution and is periodically replaced by a new etch solution, the etching batch is kept in an efficient condition.

The etching solution also contains foaming agents, which work to lessen the strong fumes and mists that emerge from the intense reactions. It’s vital to remember that at this point, the final product’s appearance is decided. No matter how well the piece is anodized or tinted, improperly etched work will show scratches or flaws.

Acid Desmutting

The aluminum develops a “smut” coating as a result of etching. The grey-to-black smut is the insoluble alloy residue left over after the aluminum has been etched away. A nitric acid solution is most frequently used to remove this smut, leaving a prepared surface ready for anodizing.

Anodizing

Place the component(s) in the anodization bath while the electrical circuit still powers it. The solution’s composition, temperature, current density, voltage, and time are just a few examples of the parameters that can change depending on the desired attributes mentioned above.

Coloring

During anodizing, you can regulate the color of the component. Depending on the oxide coating’s thickness, the visible spectrum’s nanometer-sized wavelengths can reflect light in various ways. Various colors are produced using various parameters.

Put your part in a solution of metallic salts to give it a bronze or black polish. These interact with the surface to fill the pores with a chemical substance that is either black or bronze. It is known as electrolytic coloring.

Dip coloring, which fills the pores with a dye solution, might be used if you desire a different color. Place your component after dipping it in the dye in warm DI water to stop any additional reactions. Dip coloring is the least resilient of the coloring techniques described here since the color may deteriorate over time if exposed to UV light.

Sealing

To stop future corrosion and boost performance, you must seal the tiny pores on the component’s surface after anodizing. Anodized parts may feel tacky to the touch if the pores are not sealed. Additionally, dirt, pollutants, and stains can gather in open pores.

There are three common processes for sealing pores:

Hot DI Sealing

With this technique, you submerge the component in deionized water that has been heated to nearly boiling. Boehmite, or hydrated aluminum oxide, is created when the water reacts with the component. Compared to aluminum oxide, boehmite fills the pores and takes up more space.

It is straightforward to standardize this procedure. It can, however, result in dye bleed and color leakage on dyed materials and has a significant energy cost.

Mid-Temperature Sealing

This technique, which uses metal salts in a solution like salts of nickel, magnesium, or cobalt to react with the surface and fill the pores, requires less energy than heat sealing.

This technique lessens sealing smut or surface mineral deposits and is preferable for colored components. However, it’s more challenging to control and challenging to repeat with the same accuracy.

Cold or Room-Temperature Sealing

Cold sealing chemistries frequently use nickel-fluoride formulations that interact with the porous aluminum oxide layer to generate a sealed fluoro-aluminate layer that is then deposited on the surface.

The surface is etched during this process to improve performance and adherence. Additionally, it complies with a few automotive and military standards. It can be slow, though, and may need a hot water bath to hasten the curing process, making it more difficult to manage.

What Materials Can Be Anodized?

Anodizing is most common with aluminum, but aluminum alloys, magnesium, titanium, and even stainless steel can be anodized as well. Aluminum is commonly used due the high strength, availability, and low weight. While it is considered to be a soft conductive, anodized aluminum is able to achieve a variety of colors.

However, something like titanium or even stainless steel may not be as vibrant or diverse as with anodized aluminum.

How To Anodize Aluminum

Aluminum is anodized by dipping it into an acid electrolyte bath and then running an electric current through it. The anodizing tank has a cathode mounted inside of it; aluminum serves as the anode, causing oxygen ions to be released from the electrolyte and combined with aluminum atoms on the surface of the component being anodized.

Therefore, anodizing is the enhancement of a naturally occurring phenomenon through carefully controlled oxidation.

Parameters And Properties Of Anodizing

Anodizing increases corrosion resistance and wear resistance, and provides better adhesion for paint primers and glues than does bare metal. Anodic films can also be used for some cosmetic effects with thinner transparent coatings or thicker porous coatings that can absorb dyes.

The anodizing process changes the microscopic texture of the surface and changes the crystal structure of the metal near the surface. Thick coatings are porous, so a sealing process is often needed to achieve corrosion resistance.

Anodized aluminum surfaces, for example, are harder than aluminum, but can have good wear resistance that can be improved with increasing thickness or by applying suitable sealing substances. Anodic films are generally much stronger and more adherent than most types of paint and metal plating, but also more brittle. This makes them less likely to crack and peel from aging and wear, but more susceptible to cracking from thermal stress.

Is Anodizing Aluminum Conductive?

Once the aluminum substrate goes through the electrochemical process, the result (anodized film) is considered electrically non-conductive. This is then what protects the aluminum against normal wear and tear and corrosion.

Benefits Of Anodizing Aluminum

The benefits of anodizing aluminum include:

Lower Cost – This is an inexpensive lower finishing cost type and provides greater long-term value as a result.

Non-toxic – Anodized finishes are non-toxic and can withstand high temperatures (around 1,200 degrees F).

Vibrant Color – Aluminum can be anodized well with a vast array of color and even gloss options.

Long-Lasting – The upkeep of this is quite easy as there is hardly ever any wear from fabrication or use. Anodized material can often be cleaned with mild soap and water.

Disadvantages Of Anodizing Aluminum

The disadvantages of anodizing aluminum include:

- Only certain grades of aluminum are suitable for this technique,

- Stainless steel, which is resistant to mortar, salt, chlorine, and marine environments, cannot be utilized with this product.

- This process draws from the base metal, allowing for color changes.

- In low-grade metals, no match is achievable across batches, making consistency between batches more difficult to recreate than in high-grade metals where a 95% match is possible.

Types Of Anodizing Process

Below is a list of the types of anodizing processes including:

Type I Anodize

This is typically known as chromic acid anodizing, and it is a popular method that coats the metal substrate with an oxide layer. However, chromic acid anodizing is considered to be the thinnest of the anodic coating types.

Boric Anodize – Boric-Sulfuric Acid Anodize (BSAA) is an alternative to chromic acid anodize (CAA). It builds a thin-film anodic coating and provides corrosion protection and a mechanical bond.

Features – Environmentally-friendly solution

Tartaric Anodize – Tartaric-Sulfuric Anodize (TSA) is also an alternative to CAA and also builds a thin-film anodic coating and provides corrosion protection and a mechanical bond. This is a chromated, environmentally friendly solution – typically specified in Airbus programs like the A350.

Features – Non-chromated, environmentally friendly solution

Chromic Anodize – Chromic Acid Anodize (CAA) creates the thinnest anodic while providing the same corrosion resistance as other types of anodization, such as boric or sulfuric.

Features – Includes corrosion protection, it non-conductive (provides electrical insulation), and lesser absorption of pigmentation

Type II Anodize

Sulfuric Anodize – Sulfuric Acid Anodize (SAA) is used when hardness and abrasion resistance is required on a part, and creates a surface that is harder than traditional chromic anodizing.

Type III Anodize

Hardcoat Anodize – Hardcoat anodize is created as a sulfuric acid bath, but results in a much thicker surface anode coating than traditional sulfuric acid anodizing.

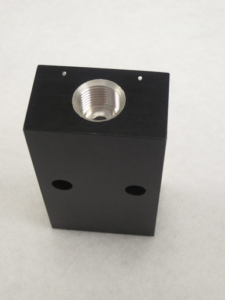

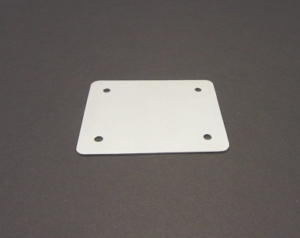

Alodine/ Chemical Film

Chemical film or chem-film is also known as conversion coating. These coatings are used to repair anodized surfaces and prevent parts from corrosion.

Which Type Of Anodizing Is The Best For You?

This really depends on what you’re looking for. For example, the thickness of the coating depends on the type. Type III anodizing has a thicker and denser coating than with Type II. Type II is a versatile coating option because of the various dye potentials in a variety of colors. This makes it a desirable choice for aluminum substrates and additionally for electronics, hardware, and even military grade weapons.

On the other hand, Type III is also used for valves, electronics, and gears but it is much thicker to help with wear-resistance purposes. Again, aluminum is a great item to use in this case because with Type III anodizing you can expect exposure to extreme wear. However, this addition makes the substrate non-conductive, abrasion-resistant, and protects against corrosion.

How To Know If The Anodizing Process Was Successful

There are many ways to tell if a part has undergone anodizing. Below are some useful ways to evaluate the success of the anodizing process:

Examine For A Matte Finish

The matte sheen that anodizing produces usually makes it clear.

Make Use Of A Basic Scratch Test

Scratch the aluminum component’s surface with a coin. If a scratch is apparent, the component was probably merely polished rather than anodized. An anodized component will have complete scratch resistance.

Dispersal Of Color

An even surface with color dispersion is the product of a successful anodizing procedure. Watch out for anodizing burns brought on by high current densities and insufficient agitation during the anodizing process as anodizing faults on your finished product.

Anodizing Aluminum Services

At Valence, we understand that you’re looking for solutions and services that save time and money. As the world’ largest independent aerospace finishing company, we are the only completely integrated solution in the supply chain.

So whether you’re looking for anodizing services, or any other finishes for your company, we have the variety and means to handle it.

Contact us today with any questions or to request a quote on your next project.