TiCad Services: Elevating Aerospace Surfaces With Titanium Cadmium Plating

The aerospace industry consistently seeks the zenith of surface engineering. Titanium cadmium plating emerges as a cornerstone technique, indispensable for components that must withstand extreme conditions. TiCad Services by Valence Surface Technology reflects decades of specialization, granting aerospace clients access to top-tier surface solutions. Our approach intertwines cutting-edge technology with robust industry experience, ensuring each project achieves new heights of excellence. With an unwavering commitment, Valence is the preferred choice for titanium cadmium plating services.

Valence offers expert surface finishing for industries like aerospace and automotive, enhancing your products. Contact us to discuss your needs and elevate your products.

What Is Titanium Cadmium Plating?

Titanium cadmium plating is a surface treatment that remarkably improves the lifespan and function of aerospace components. The electrochemical process accurately deposits cadmium and titanium uniformly across metal surfaces, forming a protective barrier. It is an intricate process, demanding precise control and deep understanding, which Valence offers with ease.

Our facilities are equipped with state-of-the-art tools ensuring the consistent application of this innovative coating. The proficiency with which we deliver titanium cadmium plating is a hallmark of Valence’s TiCad Services.

Applications Of Titanium Cadmium Plating In Aerospace

Titanium cadmium plating, a specialty of TiCad Services by Valence, has been a game-changer in the aviation industry, particularly in addressing wear and corrosion issues on aircraft. Numerous case studies showcase its successful application, notably on landing gear, where it has significantly extended life expectancy.

These success stories underscore Valence’s ability to meet the demanding challenges of the aerospace sector, offering durability and reliability that clients depend on. Furthermore, the superior corrosion resistance and reduced fretting provided by titanium cadmium plating have been instrumental in enhancing aviation safety. This improvement is well recognized by aerospace engineers, as it contributes to more reliable flights and extends the service life of aircraft. Valence’s commitment to meticulous plating techniques not only reinforces these safety improvements but also reflects their dedication to maintaining high standards and excellence within the industry.

The Role Of Titanium Cadmium Plating In Lifecycle Extension

Titanium cadmium plating, as offered by Valence Surface Tech, significantly impacts the total cost of ownership in the aerospace sector by reducing maintenance needs and prolonging component lifespan, thereby delivering enhanced long-term value to clients. Valence’s use of advanced plating techniques plays a crucial role in boosting the reliability of aerospace components. This dedication to excellence in titanium cadmium plating correlates with improved performance and fosters increased trust from their clientele.

Additionally, the extended life of components achieved through this plating process not only presents economic benefits but also supports sustainable industry practices. Valence Surface Technologies is committed to this environmentally beneficial approach, providing surface treatments that are designed to endure, thereby aligning with both economic and ecological objectives.

Technical Aspects Of Titanium Cadmium Plating

When exploring the technical aspects of titanium cadmium plating, several key factors come into play, each crucial for understanding this specialized process:

Surface Preparation And Pre-Treatment Processes

Prior to applying the titanium cadmium coating, thorough surface preparation is indispensable. This involves cleaning, stripping previous finishes, and perhaps etching to ensure proper coating adhesion. Valence Surface Tech systematically executes these critical steps, recognizing that immaculate pre-treatment is foundational for the plating’s success.

Detailed Explanation Of The Plating Procedure

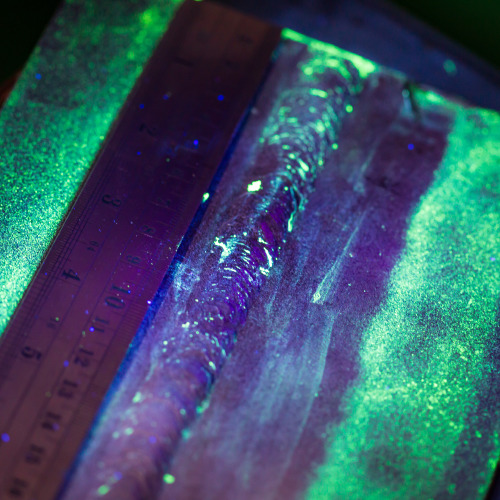

The titanium cadmium plating process requires precision. At Valence, components are submerged in a specially formulated electroplating bath where a controlled electric current deposits the metals onto the base material. This meticulous procedure ensures optimal coating characteristics for each unique aerospace application.

Controlling The Thickness And Uniformity Of The Coating

The integrity of titanium cadmium plating relies on maintaining specific thickness and uniformity. Utilizing cutting-edge technology, Valence Surface Tech meticulously controls these parameters, ensuring consistent protection across the entire component surface.

Post-Plating Treatments And Finishes

After plating, several treatments may follow to enhance the plating’s properties, such as chromate conversion coatings for additional corrosion resistance or sealants to minimize friction. Valence Surface Tech experts tailor these post-treatment processes to meet precise aerospace specifications.

Benefits Of Titanium Cadmium Plating

Titanium cadmium plating offers several benefits, particularly in industries like aerospace where material performance is critical:

Excellent corrosion resistance: Titanium cadmium plating is highly resistant to corrosion, even in harsh environments such as salt water and industrial chemicals. This makes it an ideal choice for protecting steel components in a variety of applications.

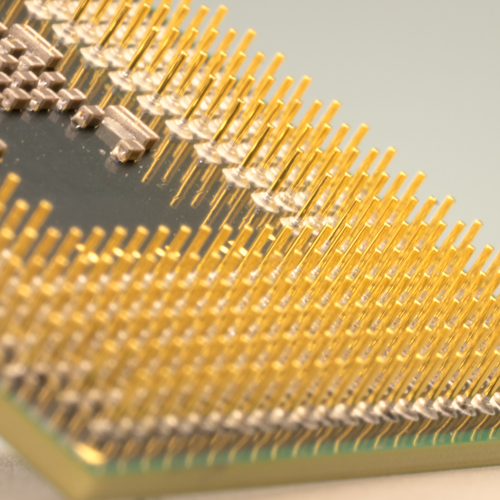

Low electrical resistance: Titanium cadmium plating has low electrical resistance, making it a good conductor of electricity. This is important for applications where electrical conductivity is critical, such as in electronics and aerospace.

Good solderability: Titanium cadmium plating has good solderability, meaning that it can be easily soldered to other metals. This is important for applications where components need to be joined together using solder.

Sacrificial protection: Titanium cadmium plating provides sacrificial protection for steel components. This means that the cadmium plating will corrode first, protecting the underlying steel from corrosion.

Ease of application: Titanium cadmium plating can be applied to a variety of base metals, including steel, copper, brass, and aluminum. It can be applied using a variety of methods, including electroplating, immersion plating, and brush plating.

Elevate aerospace technology with Valence Surface Technologies high-emissivity coatings, specialized finishes, and more. We’re committed to delivering excellence in surface finishing solutions.

Titanium Cadmium Plating And Industry Compliance

Valence Surface Tech adeptly meets the stringent Aerospace Material Specifications (AMS) with its TiCad Services, leveraging extensive knowledge and experience to ensure the highest compliance levels in the aerospace industry. Concurrently, the company is deeply committed to environmental, health, and safety (EHS) considerations.

Despite the effectiveness of titanium cadmium plating, Valence prioritizes managing its environmental and health impacts, employing best practices, and seeking continuous advancements to reduce environmental impact. This proactive approach to EHS standards reflects their dedication to responsible and sustainable operations.

Navigating Environmental Regulations For Titanium Cadmium Plating

Valence Surface Tech demonstrates its proficiency in adhering to complex environmental regulations related to titanium cadmium plating, ensuring compliance and protecting both clients and the environment. Committed to environmental responsibility, the company actively invests in research and development to discover greener alternatives to traditional plating methods, striving to balance sustainability with the high performance required in aerospace components.

Meticulous in the handling and disposal of plating materials, Valence’s processes are carefully designed to minimize environmental impact while strictly adhering to regulations. Furthermore, the company takes a leadership role in the industry, educating peers about sustainable plating practices, with the goal of promoting environmental stewardship throughout the aerospace finishing sector.

Maintenance And Care For Titanium Cadmium-Plated Components

Maintaining your titanium cadmium-plated components is essential for ensuring their longevity and optimal performance. To properly care for these specialized parts, follow these comprehensive steps:

Best Practices For Longevity

To maximize the lifespan of titanium cadmium-plated components, routine maintenance following the best industry practices is critical. Valence educates clients on proper care techniques, ensuring extended durability and performance of the plated parts.

Inspection And Quality Assurance Methods

Regular inspections and thorough quality assurance protocols are key to maintaining the integrity of titanium cadmium plating. Valence Surface Tech employs rigorous inspection techniques to detect any issues early, guaranteeing the plating’s long-term performance and safety.

Troubleshooting Common Issues With Plated Surfaces

Issues such as uneven wear or corrosion spots can compromise the effectiveness of titanium cadmium plating. Valence offers troubleshooting guidance, helping clients resolve these common issues swiftly to prevent component failure.

Choosing TiCad Services By Valence

Choosing TiCad Services by Valence involves a strategic decision-making process to ensure you are selecting the right service for your needs. Here’s a guide to help you make an informed choice:

Industry-Leading Expertise

Valence Surface Tech not only offers titanium cadmium plating but imbues each project with a deep-seated expertise unique to us. Our reputation is built on the foundation of thousands of service approvals and a vast processing capacity unparalleled in the industry. We diligently monitor every aspect of the TiCad process, ensuring adherence to rigorous industry standards. Aerospace clients can trust in our breadth of experience to navigate the complexities of regulatory requirements. Hence, when it comes to titanium cadmium plating, Valence is not just a provider but an authoritative industry leader.

Client-Centric Approach

We consciously tailor our TiCad Services to fit the distinct needs of our clients, making them active participants in the finishing process. Communication and education are at the forefront of our operations, fostering a relationship based on trust and transparency. Our team walks you through each step, guaranteeing a comprehensive understanding of the benefits and procedures involved. We empathize with the precision required by aerospace clients and match their ambition with our meticulous attention to detail. Valence Surface Technologies’ TiCad Services are more than transactions; they are enduring partnerships built on shared success.

A Focus On Quality And Delivery

Our TiCad Services are synonymous with reliability, ensuring clients receive finished components that exceed expectations. Adherence to schedules is non-negotiable, and we commit to delivering on or before the promised deadline. Each project is an opportunity to demonstrate the meticulous craft and unwavering quality control that is Valence.

Our delivery promises are not mere estimations but solid commitments upheld by our industry-leading logistics. Aerospace clients can rest assured that TiCad Services by Valence Surface Tech signify a true alignment with their quest for aerospace excellence.

Final Thoughts On Titanium Cadmium Plating

Our TiCad Services are meticulously designed to boost the performance of aerospace components to their maximum potential. Valence Surface Tech stands as a beacon of innovation and quality in the aerospace industry. Clients who choose Valence for titanium cadmium plating invest in a future of enduring excellence and unparalleled performance.

Our mission is not simply to meet industry standards but to elevate them through our dedicated efforts. Invite us to partake in your aerospace ventures, and allow Valence Surface Tech’s TiCad Services to reveal what it truly means to soar above the rest.

Enhance your aerospace, defense, medical, or space products with our advanced surface finishing solutions, improving performance, durability, and aesthetics.

Frequently Asked Questions About Titanium Cadmium Plating

What is TiCad Services?

TiCad Services is a company that specializes in cadmium plating services. They offer a variety of cadmium plating services, including:

- Rack and barrel cadmium plating

- Brush cadmium plating

- Electroless nickel plating

- Passivation

- Zinc plating

- Nickel plating

What are the benefits of cadmium plating?

Cadmium plating offers a number of benefits, including:

- Excellent corrosion resistance

- Wear resistance

- Electrical conductivity

- Lubricity

- Solderability

What are the applications of cadmium plating?

Cadmium plating is used in a variety of applications, including:

- Aerospace

- Automotive

- Electronics

- Medical

- Military

What are the environmental concerns associated with cadmium plating?

Cadmium is a toxic metal that can be harmful to human health and the environment. Cadmium plating is a regulated process, and there are a number of environmental controls that must be in place to minimize the risk of exposure.

How much does cadmium plating cost?

The cost of cadmium plating depends on a number of factors, including the size and complexity of the part, the type of plating required, and the desired thickness of the plating.

How can I find a cadmium plating service provider?

There are a number of cadmium plating service providers available. You can find a list of providers in the Thomas Register of American Manufacturers.

What is the difference between cadmium plating and zinc plating?

Cadmium plating and zinc plating are both types of protective coatings that can be applied to metal surfaces to improve their corrosion resistance. However, there are some key differences between the two processes.

What is the difference between rack and barrel cadmium plating?

Rack and barrel cadmium plating are two different methods of cadmium plating.

- Rack plating: Rack plating is used for large or irregularly shaped parts. The parts are placed on racks that are then immersed in the plating solution.

- Barrel plating: Barrel plating is used for small parts that can be tumbled together. The parts are placed in a barrel that is then rotated in the plating solution.

What is the difference between brush cadmium plating and electroless nickel plating?

Brush cadmium plating and electroless nickel plating are two different methods of selective plating.

- Brush plating: Brush plating is used to selectively plate small areas or hard-to-reach areas. A brush is dipped in the plating solution and then applied to the surface of the part.

- Electroless nickel plating: Electroless nickel plating is a non-electrolytic process that can be used to plate non-conductive surfaces. The part is immersed in a solution that contains the nickel ions and a reducing agent. The reducing agent causes the nickel ions to deposit on the surface of the part.

What is passivation?

Passivation is a process that forms a protective film on the surface of the cadmium plating to improve its corrosion resistance. The passivation film is typically formed by immersing the plated part in a solution of acid or chromate.

Sources:

- American Electroplaters and Surface Finishers Society (AESF). (2019). Cadmium plating handbook. AESF. https://www.scribd.com/document/374982852/Metal-Finishing-Guidebook

- Barbalio, M., & Balzer, T. (Eds.). (2010). Handbook of surface plating technology. Taylor & Francis. https://www.amazon.com/Advanced-Surface-Technology-Authoritative-Reference/dp/8792765238

- Bureau of Labor Statistics, U.S. Department of Labor. (2023). Occupational Outlook Handbook, Cadmium platers. Occupational Outlook Handbook. https://www.bls.gov/ooh/

- Environmental Protection Agency, U.S. Department of the Interior. (2023). Cadmium plating wastewater treatment. EPA.gov. https://www.epa.gov/stationary-sources-air-pollution/plating-and-polishing-national-emission-standards-hazardous-air

- Federal Register, Vol. 87, No. 165. (2022). Environmental Protection Agency: National Emission Standards for Hazardous Air Pollutants; Amendments for Cadmium Plating and Stripping Operations. Federal Register. https://www.gpo.gov/how-to-work-with-us/agency/services-for-agencies/ofr-publishing-services

- National Institute for Occupational Safety and Health, U.S. Department of Health and Human Services. (2023). Cadmium at work. NIOSH.gov. https://www.cdc.gov/niosh/topics/cadmium/default.html

- O’Mara, W. M., Barnes, J. A., & Koutsky, K. J. (Eds.). (2011). Handbook of nickel and nickel plating. Marcel Dekker. https://www.amazon.com/nickel-plating-kit/s?k=nickel+plating+kit

- Porter, F. C. (Ed.). (1995). Corrosion resistance of cadmium plating. Marcel Dekker. https://www.amazon.com/amsoil-metal-protector/s?k=amsoil+metal+protector

- Schlesinger, M., & Paunovic, M. (2016). Modern electroplating (5th ed.). Academic Press. https://www.sciencedirect.com/science/article/abs/pii/S0268005X22004805

- Society for Protective Coatings (SSPC). (2023). Cadmium plating. SSPC.org. https://sspc.org/

Plating Services

Cadmium Plating

Cadmium plating is a tough and versatile coating. The soft, attractive coating provides a favorable bonding surface for adhesions. It is also the preferred plating for salt-water environments due to its resistance to mold and bacteria.

Chrome Plating

Chromium plating is effective at providing excellent hardness and lubricity, reducing friction, minimizing wear, and preventing galling. In environments with corrosion or abrasion, chrome plating can withstand negative consequences on wear and tear.

Gold Plating

Gold plating advantages include good corrosion resistance, good solderability, and, when alloyed with cobalt, it has very good wear resistance. Gold is commonly used in electrical switch contacts, connector pins and barrels, and other applications where intermittent electrical contact occurs. It is also used as a radiation shield, in infrared reflectors and satellite electronic housings. Valence also offers immersion gold plating.

Manganese Phosphate

Manganese phosphate coating is a conversion coating, the formulation of which contains a manganese salt, phosphoric acid and an accelerator. This process is done under high temperature, and produces a surface that has good corrosion and wear resistance. Manganese phosphate coatings can retain oil and other lubricants.

Nickel Sulfamate

Nickel sulfamate is a plating process that provides a highly ductile plating surface with low internal stress. The versatility of the coating resists high temperatures, maintains high tensile strength, and provides ductility and elongation.

Ti-Cad Plating

Ti-Cad or titanium cadmium plating is a titanium cadmium combination plating that provides corrosion resistance on high strength steel applications. It significantly reduces the negative consequences of hydrogen embrittlement.

Tin Plating

Tin plating is used extensively to protect both ferrous and nonferrous surfaces. Tin is also widely used in the electronics industry because of its ability to protect the base metal from oxidation and corrosion. Depending on the base material, tin is used as a metal plating to maintain or impart solderability. Valence also offers tin lead plating.

Valence performs all of these services to the highest degree of care, with approvals for most prime, aerospace, and military specifications. Our products and services significantly enhance safety, long-term use, and consistency in the aerospace industry. View our specs here.

Plating Tank Sizes

| Valence Wichita | L | Valence Garden Grove | L |

|---|---|---|---|

| Cadmium Types I, II, III | 4′ | Copper Plate | 2′ |

| Electroless Ni-Mid | 4′ | Electroless Ni- Hi Phos | 6′ |

| Electroless Ni-Hi Phos | 2.5′ | Electroless Ni- Low phos | 3′ |

| Hard Chrome | 14′ | Electroless Ni- Mid phos | 7.5′ |

| Hard Chrome | 7′ | Gold Immersion | 2′ |

| TiCad | 4′ | Gold Plate – Grade A Type lll | 2′ |

| Gold Plate – Grade C, Type II | 3.5′ | ||

| Gold Plate – Grade D, Type I, Type II | 1.5′ | ||

| Gold Strike | 3′ | ||

| Nickel Plate – Bright /Semi Bright | 4.5′ | ||

| Nickel Plate – Semi Bright | 4.5′ | ||

| Nickel Sulfamate | 4.5′ | ||

| Silver Plate – Semi Bright | 3.5′ | ||

| Sliver Plate – Matte | 5′ | ||

| Tin Plate | 4.5′ | ||

| Tin/Lead Plate (60/40) | 3′ | ||

| Tin/Lead Plate (90/10-95/5) | 2.5′ |

Plating News

Chrome Coating: A Necessary Investment for Aerospace Components

Chrome coating is not just a crucial investment, it's a necessity for aerospace components that are exposed to harsh conditions during flight. It offers a range of benefits, including enhanced durability, corrosion resistance, and improved performance. If you want to...

Gold Plating: The Best Way To Protect Aerospace Components From Tarnish

In the aerospace industry, the significance of gold plating cannot be overstated. This process plays a crucial role in safeguarding vital components against the detrimental effects of tarnish and corrosion. Unlike alternative plating techniques, gold plating stands...

Understanding The Different Types Of Gold Plating

Gold plating serves as a renowned metal finishing strategy that incorporates a delicate gold layer onto a metal object's surface. This gold veneer delivers an array of advantages such as augmented corrosion resistance, superior electrical conductivity, enhanced heat...

Choosing The Right Finish: Anodizing Vs. Powder Coating

Choosing the appropriate finish for a project, such as anodizing or powder coating, can present quite a challenge. Both of these finishes have distinct advantages and considerations, making it crucial to fully grasp their unique characteristics to guide your...