Valence Springfield

West Springfield, MA 01089

Valence Eastman

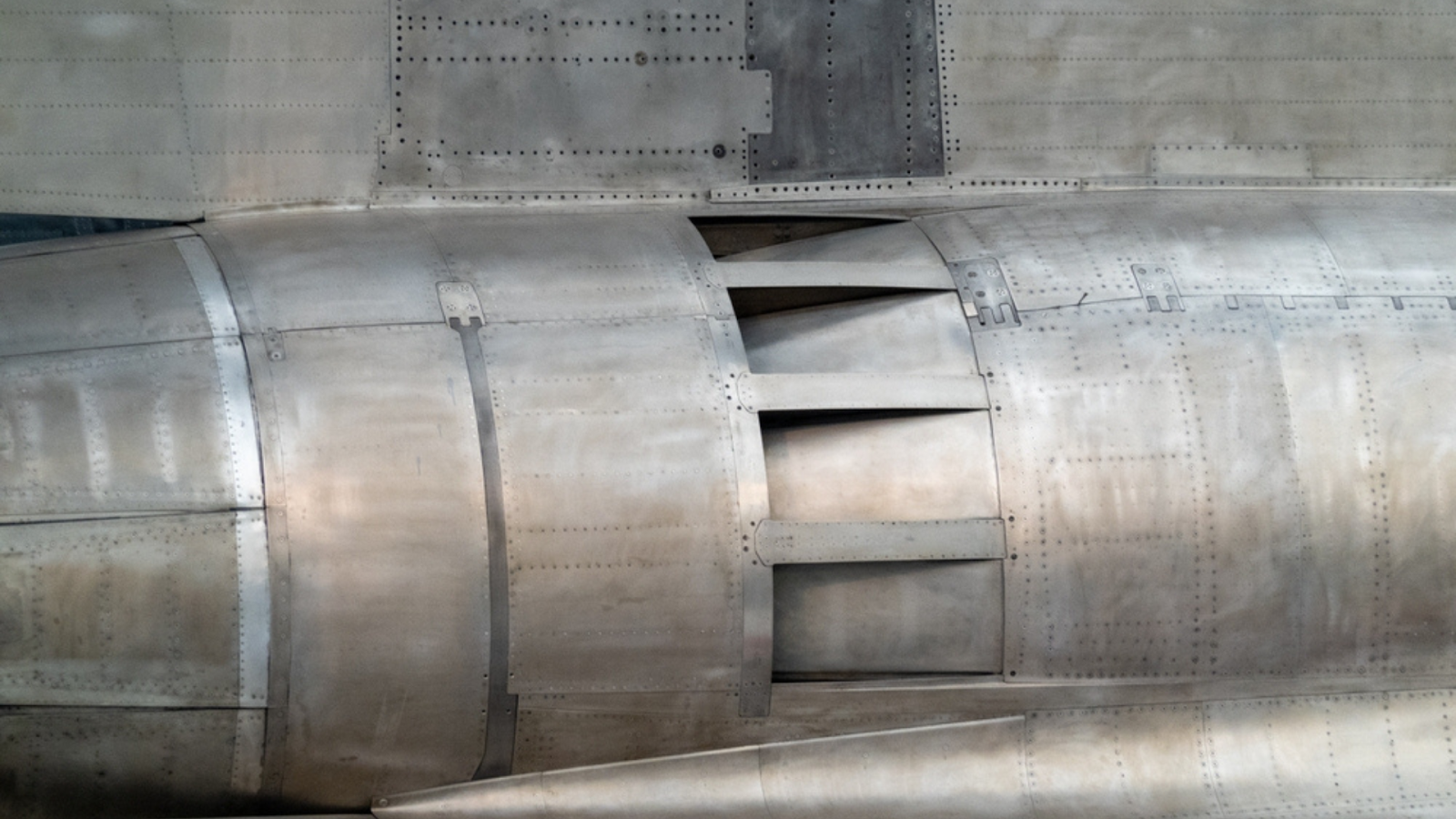

The Springfield location was founded in 1944 as the Fountain Plating Company and specializes in critical engine and air frame components. We are certified by Nadcap for chemical processing, NDT and composites and we have an AS9100 quality management system. The original test audit for Nadcap was performed at Fountain.

For more than 75 years, Valence Springfield has realized continual progress through advancement of knowledge and processing technology. Today, the site maintains a vision focused on providing the most effective plating and finishing solutions possible for customers around the world.

The West Springfield facility enables us to proudly boast of one of the largest custom and production plating sources in the Northeast, ideal for rendering an even greater range of service to our many customers in the electronics, aircraft and aerospace industries.

Full-Time Employees

Square Footage

Years Of Experience

Parts Shipped Per Year

Processing Capabilities

Plating & Finishes

Chromate Films

Chromic Acid Anodize

Chromium

Copper

Electroless Nickel Low-Phos. (1%-3%)

Electroless Nickel Mid-Phos. (5%-7%)

Electroless Nickel High-Phos. (10%-12%)

Gold

Hard Anodize

Nickel

Passivation

Phosphoric Acid Anodize

Platinum

Silver

Sulfuric Acid Anodize

Titanium (Caustic) Anodize

Specialty Processes

F-Kote II®

Electroless Nickel-Boron

(PTFE) Teflon®

Electroless Nickel Teflon®

Applied Coatings

Dry Film Lubricants

Anodize/Prime

for Adhesive Bond

Epoxy Coatings

Lacquer Coatings

Resin Coatings

Solid Film Lubricants

Inspection Methods

EIM – Etch Inspection Method

FPI – Fluorescent Penetrant Inspection

LPI – Liquid Penetrant Inspection

Mechanical Finishing

Burnishing (Dry Film Lube)

Scope of Services

On-Site Laboratory

Chemical & Metallurgical Laboratories

Atomic Absorption Unit

Hydrogen Embrittlement Rupture Bar Test

Truck Fleet for Pick Up & Deliveries

Nondestructive Testing

X-Ray Fluorescence

Baking in Vacuum & Inert Atmosphere

R&D Services Available Upon Request

Ultrasonic Cleaning

Salt Spray & Humidity Chambers

Dimensional Restoration of Base Materials

Specialty Plating

Customer Portal

Valence Springfield News

Valence Surface Technologies Acquires H&W Global Industries

EL SEGUNDO, CA, October 25th, 2021─ Valence Surface Technologies LLC (“Valence”) is pleased to announce the acquisition of H&W Global Industries, Inc. (“H&W” or the “Company”), a leading provider of surface treatment for highly engineered products in the...

Valence Surface Technologies Acquires Fountain Plating in Massachusetts

THE WOODLANDS, Texas, February 14, 2020─ Valence Surface Technologies LLC (“Valence”) is pleased to announce the acquisition of Fountain Plating Co., Inc. (“Fountain” or the “Company”), the leader in product finishing services for aircraft engine and critical...

Key Takeaways

- Valence Surface Technologies in Springfield, MA, specializes in critical engine and airframe components, offering chemical processing, NDT, and composites services certified by Nadcap and AS9100 quality management system.

- With over 75 years of experience, Valence Springfield is dedicated to providing effective plating and finishing solutions to customers worldwide, serving the electronics, aircraft, and aerospace industries.

- The West Springfield facility boasts one of the largest custom and production plating sources in the Northeast, equipped to handle various plating and finishing processes, including chromate films, anodizing, nickel plating, and more.

We will take you on an exciting voyage through the cutting-edge world of aircraft surface finishing at Valence Springfield, the top aerospace finishing firm in Springfield, Massachusetts. Find out how Springfield’s aerospace sector is influencing the future and what a crucial role it plays.

Learn more about the variety of finishing services we provide, supported by our Nadcap certifications for chemical processing, NDT, and composites. Stay engaged with the latest trends and innovations in finishing technologies that keep us ahead of the game. Learn how we are committed to sustainability, implementing eco-friendly processes for a greener tomorrow.

Ready to embark on an exploration of the endless opportunities and market potential in this ever-evolving field? Join us as we unravel the fascinating world of aerospace finishing and why Valence Springfield stands as your unrivaled partner in excellence.

Valence Springfield

Valence Springfield, founded in 1944 as the Fountain Plating Company, has become a prominent player in the aerospace and aviation industries. Specializing in critical engine and airframe components, we hold Nadcap certifications for chemical processing, NDT, and composites, reflecting its dedication to maintaining top-notch quality standards. With more than 75 years of experience, Valence Springfield continues to advance its knowledge and processing technology, ensuring the most effective plating and finishing solutions for customers worldwide. The West Springfield facility further enhances its capabilities, boasting one of the largest custom and production plating sources in the Northeast, catering to the electronics, aircraft, and aerospace sectors.

Valence Springfield’s rich history and commitment to progress make it a reliable and valuable partner for clients seeking high-quality aerospace components. Our AS9100 quality management system guarantees adherence to strict industry standards, ensuring customer satisfaction and fostering long-term relationships. Through continuous advancements and a vision focused on delivering top-tier services, Valence Springfield stands at the forefront of the industry, supporting technological advancements and meeting the diverse needs of the aerospace and aviation sectors.

Experience Aerospace Surface Finishing Excellence With Valence!At Valence Surface Technologies, we take pride in being the world’s largest independent aerospace product finishing company, providing a comprehensive and integrated solution for the aviation, defense, and space industries. Our mission is to be your most trusted partner in aerospace surface finishing. Why Choose Valence?

Discover the Valence advantage today! Experience the benefits of choosing the ONLY completely integrated solution for aerospace surface finishing. Partner with Valence and elevate the performance and reliability of your aerospace components. |

What Is Aerospace Finishing?

Aerospace finishing, sometimes referred to as surface finishing or aerospace surface treatment, is applying several procedures and coatings to aerospace components to enhance its functionality, toughness, and aesthetic appeal. To achieve strict safety, functionality, and aesthetics requirements, the aerospace industry demands premium surface treatments on parts of aircraft and spacecraft.

Processes used in aerospace finishing include plating, anodizing, painting, chemical treatments, and coatings. These procedures have a variety of uses, such as improving the components’ overall aesthetics and providing corrosion resistance, wear resistance, lubrication, electrical conductivity, and thermal protection.

As aerospace components are exposed to adverse circumstances such as high altitudes, temperature changes, humidity, and chemical exposure, aerospace finishing is essential to ensure durability and dependability. In order to meet the strict specifications of contemporary aircraft and spacecraft designs, the industry’s relentless quest for innovation and performance improvement has resulted in the development of advanced finishing technologies.

How Do Aerospace Finishing Work?

Aircraft finishing is the careful application of various procedures and techniques to aircraft components to achieve certain goals. Here is a description of the process of finishing in aerospace:

- Surface Preparation: Aerospace finishing starts with preparing the component’s surface for future processing. In order to ensure appropriate adhesion of the finishing materials, this may entail cleaning, degreasing, or removing any impurities.

- Plating and Coatings: Plating, which involves applying a thin layer of metal (such as nickel, chromium, or cadmium) to a component’s surface via an electrochemical process, is one of the main techniques used in aerospace finishing. The part’s corrosion resistance and wear qualities are improved as a result. Additionally, coatings can be added to provide particular functionality or enhance aesthetics. Examples of these coatings are heat barrier coatings and protective paints.

- Anodizing: Aluminum components are frequently treated using anodizing, a specialized electrochemical procedure, in the aerospace sector. It improves the performance and aesthetics of the metal by depositing an enduring and corrosion-resistant oxide layer on its surface.

- Chemical Treatments: Chemical processes like etching, passivation, or conversion coatings may be used in aerospace finishing. To improve adhesion, increase corrosion resistance, or get the components ready for following finishing procedures, these processes alter the surface qualities of the components.

- Non-Destructive Testing (NDT): Non-destructive testing techniques are frequently used in aerospace finishing to check the finished components for any flaws or anomalies. The components are checked to make sure they adhere to the necessary quality requirements using methods like eddy current testing, radiography, or ultrasonic testing.

- Quality Assurance: Strict quality control procedures are applied throughout the aircraft finishing process to guarantee that the components fulfill industry-specific standards and customer requirements. Audits may be conducted by certification organizations like Nadcap to verify adherence to aerospace industry standards.

- Sustainable and Eco-Friendly Practices: The aircraft industry has put more emphasis recently on adopting sustainable and ecologically friendly finishing techniques. This entails cutting back on the usage of dangerous chemicals, recycling waste, and researching eco-friendly coatings and treatments.

Benefits Of Aerospace Finishing Companies In Springfield, MA

Our dedication to excellence and use of cutting-edge technology guarantees that our clients acquire a competitive advantage and enjoy unmatched benefits. Utilizing Valence Springfield Aerospace Finishing Services has several major advantages, including:

High-Quality Finishing

Valence Springfield ensures top-notch quality in all our finishing procedures with to our more than 75 years of experience and Nadcap certifications for chemical processing, NDT, and composites. Aerospace components receive the greatest surface treatment thanks to our experience and strict quality control procedures, which improves their functionality, robustness, and overall dependability.

Comprehensive Range Of Services

Among the many finishing services provided by Valence Springfield are electroplating, anodizing, painting, coatings, and non-destructive testing (NDT). This one-stop-shop strategy streamlines our clients’ supply chains and makes project management easier by enabling them to access a wide variety of surface treatments under one roof.

Expert Technical Support

Our team of highly qualified specialists is committed to offering our clients unique solutions and competent technical assistance. Our experts are available to help at each stage of the finishing process, whether it be choosing the best finishing method or attending to particular aerospace industry requirements.

Aerospace Industry Expertise

Serving the satellite, aerospace, and defense industries is a specialty of Valence Springfield. We are able to create specialized solutions that adhere to the exacting standards of the aerospace industry because we are familiar with the special difficulties and demands that these industries face.

Cutting-Edge Technologies

As a pioneer in its area, Valence Springfield consistently makes purchases of cutting-edge tools and technology. Our cutting-edge facilities guarantee that our customers receive the most recent innovations in aerospace finishing, enhancing component performance and market competitiveness.

Environmental Responsibility

Sustainable living and environmentally friendly practices are important to Valence Springfield. In order to develop a greener aerospace industry, we work to implement environmentally friendly finishing procedures that minimize waste and hazardous materials and reduce waste.

On-Time Delivery

We are aware of how crucial on-time delivery is to the aerospace industry. We guarantee that our clients receive their finished components on time, enabling them to achieve important project deadlines, through effective project management and production procedures.

Range Of Finishing Services Offered By Valence Springfield

We take pleasure in offering a broad range of finishing services at Valence Springfield to satisfy the unique needs of the aircraft sector. Some of the main services we provide are as follows:

Electroplating

We specialize in electroplating processes, which involve depositing a thin layer of metal onto the surface of aerospace components.1 Our electroplating services include Nickel Plating, and Chrome Plating. These processes enhance the components’ corrosion resistance and wear properties, ensuring they withstand the demanding aerospace environment.

Anodizing

Our anodizing services include Sulfuric Acid Anodizing (SAA), Hardcoat Anodizing, and Chromic Acid Anodizing. Anodizing is commonly used for aluminum components to create a durable and corrosion-resistant oxide layer, adding to their performance and longevity.2

Painting and Coatings

We offer primer and topcoat application services to protect aerospace components from environmental factors and enhance their appearance. Additionally, we provide Dry Film Lubricants and High-Performance Coatings to improve the components’ functionality and performance in extreme conditions.

Non-Destructive Testing (NDT)

Our NDT services include Fluorescent Penetrant Inspection (FPI) and Boroscope Inspection. These techniques allow us to inspect aerospace components for defects or irregularities without causing damage, ensuring the highest quality standards are met.3

Trends And Innovations In Finishing Technologies

The aerospace industry is continuously evolving, and surface finishing technologies are no exception. Valence Springfield stays at the forefront of these advancements to deliver cutting-edge solutions to our clients. Some notable trends and innovations include:

Advanced Coating Materials

- High-temperature resistant coatings

- Corrosion-resistant nanocoatings

- Conductive polymers for electromagnetic shielding

Digitalization And Automation

- Computer-aided finishing process design

- Automated robotic finishing systems

Surface Analysis And Quality Control

- Advanced spectroscopy and microscopy techniques

- 3D surface profilometry

Environmental Impact Of Finishing Processes

Valence Springfield is dedicated to reducing its environmental impact as a conscientious aerospace finishing firm. We place a higher priority on environmentally friendly procedures even if surface finishing procedures are crucial for improving the performance and longevity of aeronautical components. Important projects we work on include:

Waste Reduction And Recycling

- Efficient chemical management and recycling programs

- Proper disposal of hazardous waste in compliance with environmental regulations

Energy Efficiency

- Optimized finishing process parameters to reduce energy consumption

- Adoption of energy-efficient equipment and technologies

Green Certifications

- Pursuing environmentally focused certifications and accreditations

Emerging Opportunities And Market Potential

The aerospace sector is expanding quickly, opening up new prospects and expanding the market. The requirement for trustworthy surface finishing services grows along with the demand for aeronautical components. Valence Springfield is in a good position to take advantage of these new opportunities because of:

Expanding Our Technological Capabilities

- Investing in advanced finishing equipment and technologies

- Research and development to stay ahead of industry demands

Forging Strategic Partnerships

- Collaborating with aerospace manufacturers, suppliers, and research institutions

- Exploring joint ventures and alliances to expand our reach

Enhancing Customer Satisfaction

- Continuous improvement in our service offerings

- Delivering quality finishing solutions that exceed customer expectations

Current State Of The Aerospace Industry In The City

The aerospace industry is centered on Springfield, Massachusetts, which has a thriving ecosystem of aerospace businesses and organizations. The city, which has a long history in aviation, has emerged as a center for cutting-edge aerospace technology development, manufacture, and research. As a result, Springfield draws businesses from around the globe looking for top-tier surface finishing solutions to satisfy the high standards of the aerospace industry.

Final Thoughts On Aerospace Finishing Companies In Springfield, MA

As a pioneer in the industry, Valence Springfield takes great satisfaction in offering innovative solutions that address the various requirements of the aerospace, defense, and space industries.Because they provide specific surface treatments that have a big impact on the functionality, durability, and general quality of aerospace components, aerospace finishing businesses in Springfield, Massachusetts, are essential actors in the aerospace industry.

Springfield, Massachusetts, has developed into a significant hub for aerospace activity thanks to its long history in aviation and strong emphasis on research, development, and innovation. The value of precise surface finishing is increasing along with the need for high-quality aerospace components. Valence Springfield stands out as the leading option for businesses looking for top-notch surface finishing services because we are committed to delivering results that are extraordinary and surpass industry standards.

At Valence Surface Technologies, we take our role as the world’s largest independent aerospace product finishing company very seriously. With a deep understanding of the critical nature of surface treatments in the aerospace sector, we have tailored our services to meet the most stringent requirements and adhere to the highest quality standards.

Are you looking to elevate your aerospace experience with the cutting-edge technology that Valence provides? Reach out to us and reach new heights in aerospace industry!

You may check out our other related articles:

- Chrome Coating: A Necessary Investment for Aerospace Components

- Gold Plating: The Best Way To Protect Aerospace Components From Tarnish

- Explaining the Differences Between Hardcoat and Other Anodizing Methods

Frequently Asked Questions About Aerospace Finishing Companies In Springfield, MA

What industries does Valence Springfield cater to?

Valence Springfield specializes in providing surface finishing solutions for the commercial aerospace, defense, space, and satellite industries.

How does Valence Springfield ensure the confidentiality of sensitive project information?

Valence Springfield takes data security and confidentiality seriously. We have strict protocols in place to protect sensitive project information, and all our employees sign non-disclosure agreements (NDAs) to maintain confidentiality.

What types of coatings do you offer for aerospace components?

We offer a wide range of coatings, including nickel plating, chrome plating, anodizing (SAA, hardcoat, and chromic acid), chemical film coatings, and high-performance paints and coatings.

How does Valence Springfield ensure the quality of finishing services?

Valence Springfield maintains strict quality control measures, utilizing advanced surface analysis techniques and adhering to industry standards to ensure the highest quality of finishing services.

Can Valence Springfield handle large-scale finishing projects?

Absolutely, Valence Springfield has the capacity and expertise to handle projects of all sizes, from small components to large-scale aerospace structures.

How do I request a quote for finishing services?

To request a quote or inquire about our services, you can visit our website and fill out the contact form or call our customer support team directly.

Is Valence Springfield certified in the aerospace industry?

Yes, Valence Springfield holds various certifications and approvals from aerospace industry authorities, demonstrating our commitment to quality and compliance.

What is the typical turnaround time for finishing projects?

The turnaround time for finishing projects can vary depending on the complexity and scope of the project. We strive to provide efficient and timely services to meet our customers’ requirements.

Does Valence Springfield offer non-destructive testing services?

Yes, Valence Springfield provides non-destructive testing services, including fluorescent penetrant inspection (FPI) and boroscope inspection for detecting surface defects.

Can Valence Springfield handle custom finishing requirements?

Absolutely, Valence Springfield is experienced in handling custom finishing requirements. Our technical team can work with you to develop tailored solutions to meet your specific needs.

Sources:

- Electroplating – an overview | ScienceDirect Topics. (n.d.). Www.sciencedirect.com. https://www.sciencedirect.com/topics/materials-science/electroplating

- What is Anodizing? The Finish of Choice | AAC. (2018). Anodizing.org. https://www.anodizing.org/page/what-is-anodizing

- Discover Nondestructive Testing. (2021). Asnt.org. https://www.asnt.org/MajorSiteSections/About/Discover_Nondestructive_Testing.aspx