Part Marking

As aircraft and defense systems rely on a myriad of parts, each with its specific function and importance, the ability to accurately identify and track each component is paramount. Part marking serves as the backbone for this process, facilitating maintenance and compliance with rigorous industry standards and also enhancing the reliability and safety of aerospace and defense operations.

Understanding Part Marking

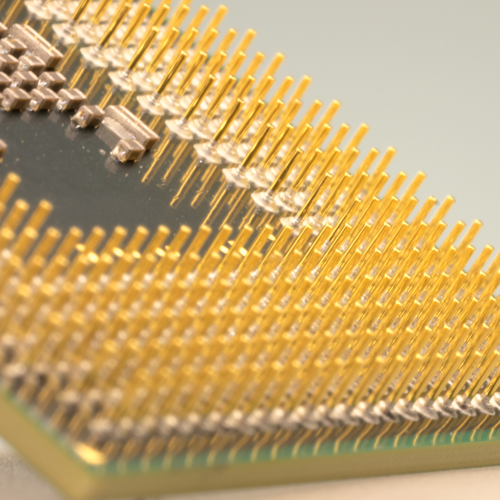

Part marking refers to the process of applying identification codes or markings to individual components of machinery or equipment. In the aerospace and defense industries, these markings are not merely for identification; they serve as critical data points for tracking the lifecycle of each part. This includes its origin, specifications, production date, and maintenance history.

Part marking extends beyond simple identification, encompassing aspects such as quality control, regulatory compliance, and ensuring the safety and reliability of the equipment. Markings must be durable and legible throughout the part’s lifecycle, capable of withstanding the harsh conditions often encountered in aerospace and defense applications.

The Importance Of Part Marking In Aerospace And Defense

Every component of an aircraft or defense system is integral to its overall performance and safety. Traceability, facilitated by precise part marking, allows for the meticulous tracking of each component’s history and performance, enabling quick responses to any issues that may arise. Compliance with industry standards and regulations is another cornerstone of part marking in these sectors. Regulatory bodies such as the FAA in the United States mandate strict adherence to part marking standards to ensure safety and reliability.

Part Marking Techniques

Among the methods we use are:

Tags

Tags provide a versatile and non-invasive option for part marking. These are typically made from durable materials such as metal or high-grade polymers and are attached to parts through adhesives, rivets, or ties. Tags can carry detailed information including serial numbers, manufacturing data, and QR codes, making them an excellent choice for items where direct marking may compromise the part’s integrity or where frequent updates to the information are needed.

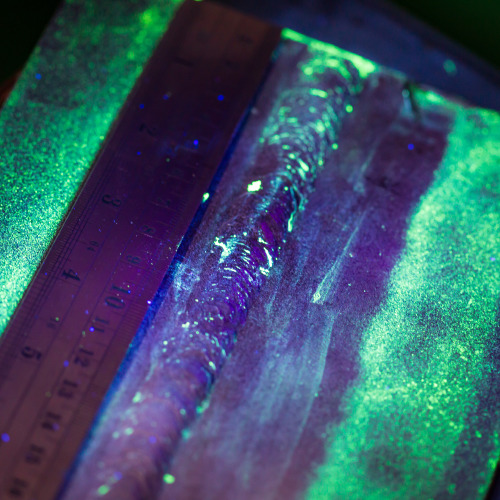

Laser Etching

Laser etching uses a laser to remove material from the surface of a part to create a visible mark. This method is similar to laser engraving but generally affects only the very surface of the material, making it ideal for thin-walled components or parts where depth penetration could be harmful.

Laser etching can produce highly detailed markings, including alphanumeric characters, barcodes, and logos, with excellent clarity and durability. It’s suitable for a wide range of materials, offering a permanent solution that can withstand harsh environmental conditions without fading or wearing away.

Digital Paint Marking

Digital paint marking is an innovative approach that uses digital technology to apply paint-based markings directly onto parts. This technique combines enhanced durability with the flexibility of ink jet marking, allowing for the application of complex images, detailed text, and precise color codes directly onto the surface of components.

Digital paint marking is particularly valuable for applications requiring color-coding, branding, or detailed instructional markings. The paint used in this process is formulated to adhere strongly to various substrates and resist environmental stressors, ensuring long-term legibility and adherence.

Ink Identify

Ink identify, or ink-based identification, involves the application of specialized inks to mark parts with necessary information. This method can range from simple stamping to sophisticated printing techniques that allow for the incorporation of variable data, barcodes, and even anti-counterfeit features.

The choice of ink and application technique can be customized to ensure optimal performance on different materials, including metals, plastics, and composites, providing a versatile solution for parts that require temporary or semi-permanent markings.

Valence Adheres To Industry Standards

When it comes to part marking, the accuracy, repeatability, and reliability of the procedure are all necessary to achieve the strict industry requirements and regulations.

These standards dictate everything from the size and depth of marks to their location on the part, ensuring that markings contribute to the part’s traceability and integrity without compromising its functionality or durability.

Traceability And Quality At Valence

Every marked part carries with it a history of its manufacture, usage, and maintenance, enabling a level of oversight and accountability that is vital in these sectors. We leverage advanced part marking technologies to ensure that every component can be traced back through its lifecycle.

This commitment to traceability not only helps our clients meet their regulatory obligations but also enhances the overall reliability and safety of the equipment and systems in which these parts are used. By integrating state-of-the-art technologies and adhering to stringent quality control measures, we provide part marking solutions that ensure each component’s performance and reliability are never compromised.

Valence’s Approach To Part Marking

State-Of-The-Art Technology

Our facilities feature state-of-the-art equipment for digital paint marking, ink identification, laser etching, and more. This enables us to provide adaptable solutions that span a wide range of material types and part configurations.

We ensure high precision and efficiency in our marking processes, capable of producing marks that are not only compliant with industry standards but also optimized for legibility, durability, and minimal impact on the part’s integrity. Our technology-driven approach enables us to handle projects of any scale, from small, custom orders to large production runs, with consistent quality and turnaround times that meet our clients’ demanding schedules.

Custom Solutions For Unique Requirements

Our team of experts works closely with clients to understand their specific requirements, including material considerations, part geometry, and compliance needs. This collaborative approach allows us to develop and implement marking solutions that are precisely tailored to each project’s specifications.

Our ability to customize our services not only sets us apart but also ensures that we can adapt to the evolving needs of the aerospace and defense industries.

Frequently Asked Questions

What standards govern part marking in aerospace and defense?

Key standards include SAE AS9132 (Aerospace Industry Standard), MIL-STD-130 (U.S. Military Standard for Marking of U.S. Military Property), and ISO 9001 for quality management systems.

What are the benefits of RFID tags in part marking?

RFID tags allow for non-contact reading, store more data than traditional marking methods, and can be updated with lifecycle information, improving inventory and maintenance tracking.

How do regulations impact part marking in aerospace and defense?

Regulations ensure that part marking methods meet safety, traceability, and quality standards, requiring durable, legible, and permanent marks to support the identification and tracking of components.

Can part marking withstand harsh environments?

Yes, methods like laser engraving and chemical etching are designed to produce marks that withstand extreme temperatures, corrosion, and wear typical in aerospace and defense environments.

How is part traceability ensured in aerospace and defense?

Through unique identifiers and databases that log the history, production, and deployment of each part, ensuring that any component can be traced back to its origin.

What is a UID (Unique Identification) in part marking?

A UID is a system of marking parts with unique identifiers that meet specific standards (like MIL-STD-130) to support lifecycle management and traceability.

What are the challenges in aerospace and defense part marking?

Challenges include ensuring durability of marks, compliance with international standards, adapting to new materials and technologies, and maintaining readability in harsh conditions.

How do companies ensure compliance with part marking standards?

By adhering to relevant industry and military standards, conducting regular audits, and using approved marking methods and technologies.

What role does part marking play in maintenance and repairs?

It enables precise identification of parts for efficient maintenance, repairs, and replacements, and helps in managing inventory and ensuring the use of genuine components.

What future trends are expected in part marking for aerospace and defense?

Trends include increased use of RFID and other digital technologies for dynamic data storage, integration with blockchain for secure traceability, and adoption of more environmentally friendly marking methods.

Other Services and Custom Solutions

Sub-Assembly

Valence offers simple assembly such as nutplates, fasteners, and bushing installations, and post assembly paint. Valence offers intermediate assembly operations prior to topcoat application.

Grinding

Grinding is an abrasive machining process that uses a grinding wheel to improve the surface finish of a part. This is often used as a finishing operation post plating.

Honing

Honing is an abrasive machining process that uses an abrasive stone to create a precision surface on a metal part.

Lab Testing

Valence provides a variety of lab testing procedures and types, including hardness and conductivity, corrosion, mechanical, metallurgical and much more. We also offer additional testing such as solderability, and purity.

Part Marking

Part marking is an identification process used to serialize a part for traceability purposes, methods include tags, laser etching, digital paint marking, ink identify and more. Valence offers a variety of different part marking types to suit your application.

Vendor Managed Inventory

Valence can partner with you to manage your entire outside processing spend, including inventory management and the ability to drop ship parts directly to your customer. We can work to manage your spend with us, or even other metal finishing suppliers.

Masking

Masking is the process of covering holes and surfaces before finishing so that the treatment only affects a designated area. Valence employees have extensive experience with complex masking using various materials such as tape, glue etc.

Clean & Etch

Titanium part manufacturing results in a surface that cannot bond, and does not accept bonding primers. An alkaline peroxide etching process, also known as clean and etch, leaves a surface texture well suited to adhesive bonding and the application of bonding primers.

Stress Relief Baking

Stress relief baking minimizes stresses caused by the machining and cutting of a part during manufacture. This reduces the likelihood of unwanted dimension changes in parts that often require tight tolerances.

View our specs here.

Custom Services News

What Is A Low Earth Orbit Satellite (LEO)?

In an era where connectivity and data exchange have become fundamental pillars of our society, LEO communication satellites emerge as a game-changer. These remarkable technological marvels have revolutionized our interconnected world, delivering many services and...

The Benefits Of Precision Finishing For The Aerospace Industry

Explore the importance of precision finishing in the aerospace industry. Discover key technologies and techniques used for optimal safety and…

Magnetic Particle Inspection (NDT)

Read on to learn about magnetic particle inspection in order to detect defects and prevent any improper manufacturing before you…