Passivation of Stainless Steel

The passivation process involves the removal of iron or iron compounds from the surface of stainless steel by chemical dissolution, a treatment with an acid solution that will remove the surface contamination without significantly affecting the stainless steel itself. These contaminants are potential corrosion sites that result in premature corrosion, that ultimately result in deterioration of the component if not removed.

Metal passivation is the chemical treatment of stainless steel with a mild oxidant, such as a nitric acid solution, for the purpose of enhancing the spontaneous formation of the protective passive film. Ultimately, passivation is a combination of both

We provide passivation to a number of specifications. One of the most common is QQ-P-35C, but take a look at all of our approvals.

Request a quote today, or contact us to learn more about how the stainless steel passivation process can benefit your application

Cleaned part after passivation

Passivation Of Stainless Steel

From construction to automobiles and even cookware. You’ll find stainless steel everywhere. The material is a perfect choice for a variety of situations because of its apparent longevity, performance, and excellent strength.

However, stainless steel still undergoes corrosion very slowly. There are many inherent properties of the alloy that keep it protected from corrosion, but stainless steel passivation is one process that all types of stainless steel parts must go through.

This article will take a look at the passivation of stainless steel and discuss its process, advantages, and prevalent standards in the industry.

What Is Passivation Of Stainless Steel?

The process of treating or coating a metal with passivation lowers the surface reactivity of the metal to chemicals. In order to prevent rust on stainless steel, passivation entails removing any free iron from the metal’s surface using an acidic solution. The other alloy constituents (primarily chromium, but frequently nickel as well) are left behind as a surface layer over the underlying steel when the surface iron is removed.

These substances react with oxygen in the air to create an oxide layer that shields the rest of the steel from corrosion. The corrosion-resistant surface is susceptible to mechanical, thermal, and chemical damage.

When that occurs, iron is exposed, which makes the item once more susceptible to rusting. Passivation may therefore need to be carried out frequently. Exposure to substances like cleaning agents, bleach, or salt (oceanic environments) in both residential and commercial settings will increase the need for routine passivation of the stainless steel.

How Does It Work?

An iron-based alloy, stainless steel is typically made up of iron, nickel, and chromium. The presence of chromium in stainless steel is what gives it its ability to resist corrosion. Chromium reacts with oxygen (air) to form chromium oxide, which coats the surface of stainless steel and prevents the underlying iron from rusting. Passivation is used to speed up and improve the formation of the chromium oxide layer.

Free iron from the surface of stainless steel is dissolved while the chromium is left unaltered by immersion in an acid bath. The free iron is chemically removed by the acid, leaving behind a uniform surface with more chromium than the underlying substance.

Stainless steel is an iron-based alloy typically composed of iron, nickel, and chromium. Chromium is a metal that gives stainless steel its ability to resist corrosion. Chromium and oxygen (air) react to form chromium oxide, which coats the stainless steel’s surface and stops the iron below from rusting. The formation of the chromium oxide layer is sped up and improved through the use of passivation.

Stainless steel that has free iron on its surface is dissolved in an acid bath, but the chromium is unaffected. The acid chemically removes the free iron, leaving a uniform surface that contains more chromium than the underlying material.

What Passivation Is Not

Not Electrolytic: In contrast to electrolysis, passivation is a chemical process. In contrast to electropolishing or anodizing, passivation does not rely on electrochemical reactions.

Not for removing scale: After heat treating or welding, the oxide scale on machined parts cannot be removed by passivating.

Not a Coat Of Paint: Stainless steel’s color or surface appearance is not altered by passivation. Metals don’t need to be passivated before being painted or powder coated.

When Is Passivation Of Steel Required?

Passivation is a post-fabrication procedure used to manipulate stainless steel after welding, grinding, cutting, and other machining operations. Passivating might not be necessary because stainless steel naturally resists corrosion in the ideal environment.

However, any of the following can prevent the formation of the oxide film that prevents corrosion under typical, realistic circumstances:

- Foreign material in a manufacturing environment (shop dirt, grinding swarf)

- Sulfides added to the stainless steel for improved machinability

- Particles of iron from cutting tools are embedded in the surface of stainless steel parts.

To restore a consistently corrosion-resistant surface, such contaminants must be eliminated right down to the surface grain boundaries. These problems are resolved by the passivation process.

Passivation Methods

Below is a list of passivation methods to consider:

Nitric Acid

As the traditional passivation technique, nitric acid on stainless steel has the benefit of being a tried-and-true method. For those who are determined to use nitric passivation, there are numerous options to enhance performance with the specific grade of stainless steel.

Less corrosion-resistant stainless steel grades are more susceptible to etching, also known as flash attack, during nitric acid passivation. The following strategies could be applied to lessen that risk:

- Addition of sodium dichromate to the nitric acid

- Higher nitric acid concentration

- Higher temperature of nitric acid.

Be aware that while these options lessen the risk of etching, they do raise the dangers that hazardous chemicals pose to worker safety. Hexavalent chromium compound sodium dichromate is a known carcinogen.

Since nitric acid is a dangerous chemical that releases toxic and corrosive fumes, ventilation and safe chemical handling must be given extra consideration. Nitric acid has a rapid ability to produce severe chemical burns despite not being a known carcinogen. Nitric acid emissions have an impact on the ozone layer and contribute to acid rain and smog when they are released into the atmosphere. All of this explains why there are strict regulations regarding worker safety and environmental protection for the industrial use of nitric acid.

Nitric Acid With Sodium Dichromate

Nitric acid passivation is accelerated or improved with the addition of sodium dichromate to some specific alloys. Nitric acid bathing is more dangerous when combined with sodium dichromate, making it a less popular choice.

Citric Acid

Nitric acid passivation can be substituted with citric acid passivation for safety and environmental reasons. Because it is an organic acid derived from citrus fruits like oranges, handling citric acid by workers is safe. Citric acid fumes do not pose a threat to human health or the environment. With almost all grades of stainless steel, citric passivation is effective and complies with all industry standards.

Citric acid was once avoided by some manufacturers because of possible organic growth and molding problems. Citric acid has improved thanks to new biocide formulations that stop organic growth in solutions. These new developments have made it possible for smaller manufacturers to bring their passivation process in-house, even though they had little to no prior experience with chemical handling.

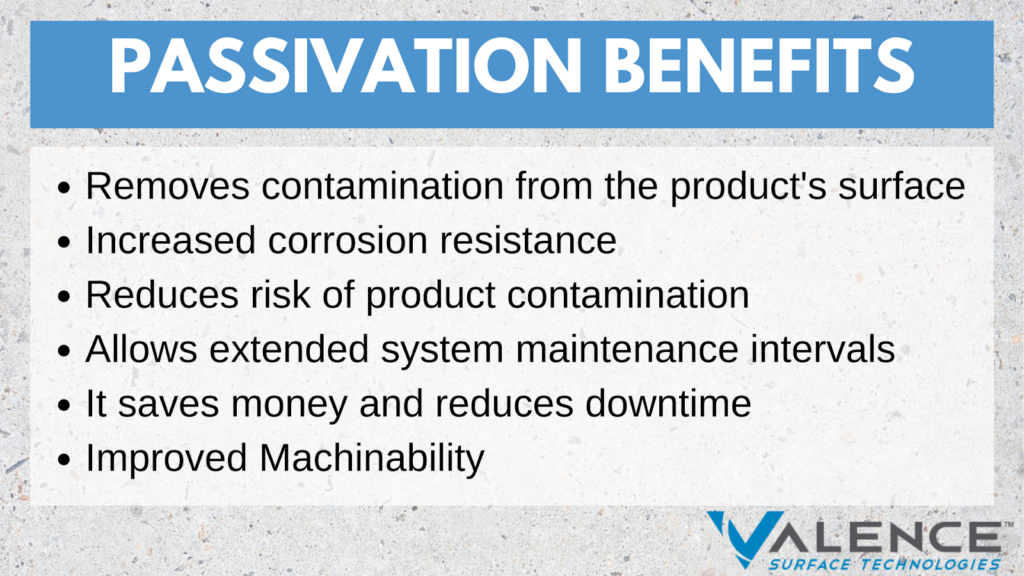

Benefits of Passivate Stainless Steel

The benefits of passivate stainless steel include:

Removes Contamination From The Product’s Surface

The simplicity of cleaning stainless steel is one of its benefits, as was already mentioned. However, the cleaning procedure itself may produce risks that could harm the item’s performance in the future. The passive layer can be harmed by abrasive chemical cleaners because it is only a few Angstroms (or molecular levels) thick.

Additionally, it is extremely vulnerable to mechanical damage from both abrasive cleaners and the cleaning tools themselves. The impact and movement of dry parts inside the vessel or piping itself can cause additional damage by abrading the chromium oxide and removing or weakening it.

Increased Corrosion Resistance

Along with cleaning up contamination, the chemical passivation process also renews and enhances the chromium oxide layer, which increases the steel’s corrosion resistance. Beyond surface iron, the alloy of stainless steel itself also poses a risk of corrosion. Metallic ions in the metal, including iron, will gradually move through the spaces between its crystals.

Eventually, iron can emerge in the passive layer from the bulk alloy through the middle, nickel-rich transition layer, providing fresh opportunities for iron oxide to form. Frequently occurring passivation procedures eliminate those iron atoms before they can do any harm.

Passivation Reduces The Risk Of Product Contamination

Contrary to chrome and chromium oxide, iron is a very chemically reactive substance that can combine with water or other ingredients to form undesirable compounds that can lessen, if not completely ruin, a product’s effectiveness.

Additionally, passivation binds (chelates) with other contaminants, enabling them to be removed with the passivating solution and flushed out of the system along with any free iron that may still be present.

Passivation Allows Extended System Maintenance Intervals

The amount of time between such intervals is increased by renewing the chemically passive layer through a routine schedule of passivation treatment, which eliminates the need for a complete system shutdown to clean and restore the stainless steel components.

As a result, it is crucial to start routine passivation treatments before commissioning a new vessel or system because passivation will clear away any debris from the building process.

It Saves Money And Reduces Downtime

Regular passivation helps lower the possibility of unplanned system shutdowns in addition to lengthening the intervals between the necessary but expensive planned system maintenance intervals. Passivation lowers the risk of contamination from the system itself while also lowering the possibility that such contamination will result in the loss of an entire production lot.

The unplanned cost of taking the system offline in terms of rescheduling and other logistical considerations is frequently equal to the costs in lost material. The “additional” cost of routine passivation becomes a worthwhile investment when you factor in the cost of identifying and removing the contamination source, as well as the associated cleaning before reactivating the system.

Improved Machinability

As was mentioned, in addition to iron, carbon, and chromium, stainless steel contains a variety of other elements. It’s important to choose materials carefully and take into account the impact of each component.

To better understand it, think about the example of carbon content. All steels contain some carbon, and the amount affects the material’s physical characteristics. Typically, materials with more carbon have harder and higher tensile strengths. However, it also entails reduced ductility and more challenging machining. Similar results are produced by chromium, which is also primarily in charge of giving steel its corrosion-resistant qualities.

Passivation of stainless steel does not alter the composition of the metal, thereby maintaining its machinability. Instead, it makes the most of the alloy’s chromium content to maximize corrosion resistance and improve overall durability.

Steps Of Passivation Of Stainless Steel

The steps of passivation of stainless steel include:

Clean

Every time, cleaning should come first. To achieve the highest level of corrosion resistance, the surface must be thoroughly cleaned of any grease, coolant, or other shop debris. You can carefully wipe away any shop dust or machining chips from the part. To remove machining oils or coolants, use a commercial degreaser or cleanser. It might be necessary to grind away foreign material, such as thermal oxides, or use techniques like acid pickling.

Sometimes a machine operator will omit the fundamental cleaning, believing falsely that cleaning and passivating will both occur as soon as the grease-covered part is submerged in an acid bath. That never occurs. Instead, the acid and contaminating grease combine to create gas bubbles. These bubbles assemble on the workpiece’s surface and obstruct passivation.

A “flash attack” is made even worse by contamination of the passivating solution, which can occasionally contain high levels of chlorides. The flash attack results in a heavily etched or darkened surface rather than the desired oxide film with a shiny, clean, corrosion-resistant surface—a deterioration of the very surface that passivation is intended to enhance.

To achieve the desired hardness and mechanical properties, parts made of martensitic stainless steels—which are magnetic, have a moderate level of corrosion resistance, and have yield strengths of up to about 280 ksi [1930 MPa]—are heated to a high temperature and then tempered. Precipitation hardenable alloys can be solution treated, partially machined, aged at lower temperatures, and then finished machined. These alloys offer a better balance of strength and corrosion resistance than the martensitic grades.

If this is the case, any remaining cutting fluid must be thoroughly removed from the parts before heat treating them. Otherwise, the parts will oxidize too quickly from cutting fluid residue. After the scale is removed using acidic or abrasive techniques, this condition may produce undersized parts with a pitted finish. Cutting fluids may cause surface carburization, which decreases corrosion resistance, if they are left on bright-hardened parts, such as those that have been in a vacuum furnace or protective atmosphere.

Passivate

The next step is to use an acid bath to completely remove all traces of iron from the surface. You can use two stainless steel passivators for that purpose. Citric acid is the first option, followed by nitric acid, which can also be used with sodium dichromate.

The passivation process can be started in a safe and affordable manner using citric acid passivation. It doesn’t release any toxic gas and doesn’t endanger the environment or the people operating it. Citric acid is not very well-liked, though, due to its propensity to encourage the growth of organic substances like mold. Even though recent technological developments have reduced this issue, it still exists.

The other option, nitric acid passivation, is a typical alternative that has historically been well-liked in the sector. You get more durability and a more efficient molecular distribution. However, the processing time suffers as a result of these qualities. Nitric acid also has a hazardous classification and emits poisonous fumes that are bad for the environment.

You have the option of combining nitric acid with sodium dichromate to address the lengthy processing time. But keep in mind that doing so would increase the toxicity and cause you more issues.

Whatever method you decide to use. Immersion would cause stainless steel to passivate, which would form a shield around the surface and shield your steel part from corrosion and contamination for an extended period of time.

Testing

The surface of passivated parts is frequently subjected to tests. The query is: “Did passivation optimize the corrosion resistance of the free-machining grades and remove free iron?”

It’s crucial that the test design matches the grade being assessed. Perfectly acceptable material will fail a test that is too strict, while unsatisfactory material will pass one that is too lenient.

The best evaluation environment for the 400 series precipitation-hardening and free-machining stainless steels is a cabinet that can sustain 100% humidity (samples wet) at 95°F (35°C) for 24 hours. Usually, the most important surface is the cross-section, especially for grades that can be freely machined. The sulfides’ intersection with this surface, which is elongated in the working direction, is one explanation for this.

To allow any moisture to run off, critical surfaces should be positioned upward but at an angle of 15 to 20 degrees from the vertical. The material will be virtually rust-free if it has been passivated properly, though it might exhibit some light staining.

An evaluation of austenitic non-free-machining stainless grades using a humidity test is also possible.

When tested in this way, liquid water droplets should be visible on the surface of the samples, revealing free iron through the development of rust.

The “Standard Recommended Practice for Cleaning and Descaling Stainless Steel Parts, Equipment and Systems,” ASTM A380, offers a quicker method. This test involves swabbing the component with a copper sulfate/sulfuric acid solution, keeping it wet for six minutes, and then checking for copper plating.

The part can also be submerged in the solution for six minutes as an alternative. Iron dissolving causes copper plating. Surfaces of parts intended for use in the processing of food should not be subjected to this test. Additionally, it should not be applied to the 400 series martensitic or lower-chromium ferritic stainless steels due to the possibility of false-positive results.

Historically, passivated samples have also been evaluated using the 5% salt spray test at 95°F (35°C). In general, it is unnecessary to perform this test, which is too demanding for some grades, to determine whether passivation was successful.

Do’s And Don’ts Of Steel Passivation

Here are some do’s and don’ts that may help you passivate successfully:

- Before passivating, DO clean first, removing all oxide or heat tint particles.

- DO avoid chlorides, which when used in excess can lead to dangerous flash attacks. Use only high-quality water with a chloride content of no more than 50 parts per million (ppm) whenever possible. The majority of the time, tap water suffices, and up to several hundred ppm of chlorides may occasionally be tolerated.

- To prevent a loss in passivation potential that could cause a flash attack and damaged parts, DO replace baths on a regular basis. Baths should be kept at the proper temperature because an attack could be localized if the temperature is out of control.

- DO keep strict replacement schedules for solutions during high-volume production runs to reduce the chance of contamination. To evaluate the effectiveness of the bath, use a control sample. Change the bath if the sample is being attacked.

- DO designate specific machines to fabricate stainless steels only; continue to cut stainless steels with your preferred coolant at the expense of all other metals.

- DO treat each piece separately to prevent metal-to-metal contact. This is particularly crucial when free-machining stainless steels because it’s important for passivating and rinse solutions to flow freely in order to diffuse corrosion products from sulfides and prevent acidic pockets.

- DON’T passivate parts made of stainless steel that have undergone carburization or nitriding. The corrosion resistance of parts treated in this way may be reduced to the point where they are vulnerable to attack in the passivating tank.

- DON’T use iron-containing tooling in an unexceptionally clean shop (floor, equipment, coolant, etc.). Using carbide or ceramic tools will help you avoid steel grit.

- DON’T forget that if parts are improperly heat treated, an attack can happen in a passivating bath. To become corrosion-resistant, high-carbon, high-chromium martensitic grades must be hardened. After a subsequent temper, passivation is frequently carried out at a temperature that preserves corrosion resistance.

- DON’T overlook the nitric acid concentration in the passivating bath. It should be checked periodically using a simple titration procedure.

- DON’T passivate more than one stainless steel at a time. This discipline can prevent costly mixups and avoid galvanic reactions.

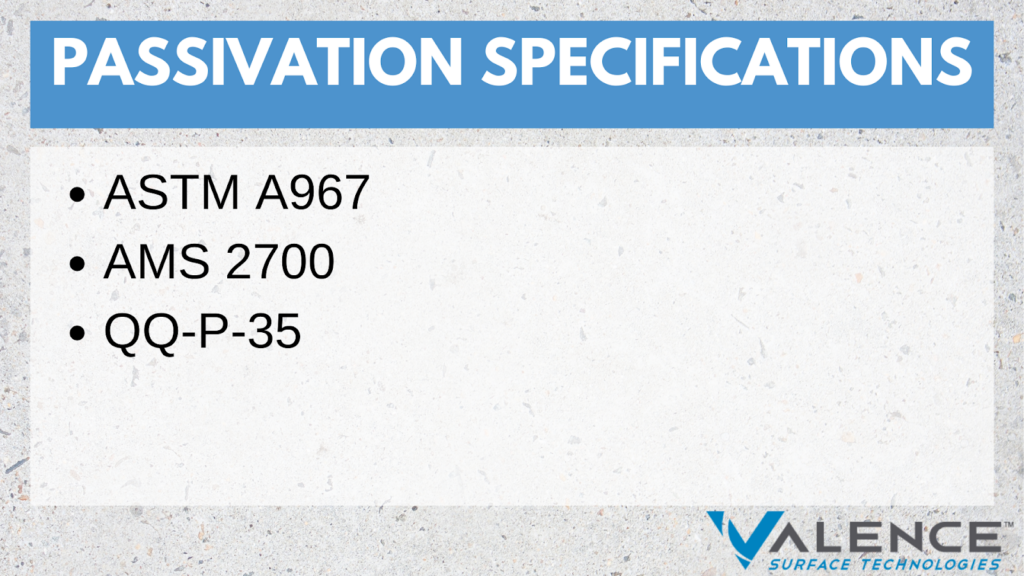

Passivate Stainless Steel Specifications

All of the passivation techniques listed in ASTM A967, AMS 2700, and QQ-P-35 are available at Valence Surface Technologies. We can also satisfy the needs of any nitric or citric acid stainless steel passivation techniques that are company-specific. Additionally, our business offers Carpenter stainless steel passivation.

A-A-A process to passivate difficult stainless steel alloys, such as 303 or 416 alloys that are high-sulfur free machining and 440 stainless that is high in chromium (reference: A-A-A Passivation Methods article in our Metal Finishing White Papers section). For the purpose of maintaining the bright surfaces of stainless components like machined faces and centerless ground 303 or 416 stainless steel shafts, inhibited passivation solutions are available.

Unfortunately, very few part prints specify the precise approach to take. As a result, finishing job shops are free to use any practical technique they have access to, producing parts that have been passivated but are not truly passive.

Our wealth of passivation experience guarantees that the appropriate passivation technique will be chosen to match the particular stainless steel grade. Advanced Plating Technologies offers complete in-house testing services, such as high humidity, salt spray in accordance with ASTM B117, and potassium ferricyanide, to certify the effectiveness of our stainless steel passivation.

The three specifications that Valence Surface Technologies most frequently certifies for stainless steel passivation are ASTM A967, AMS 2700, and QQ-P-35. In addition, we can certify passivation to the majority of company-specific passivation requirements as well as ASTM A380, ASTM F86, AMS 2700C, and ISO 16048. The following is a summary of stainless steel passivation methods in accordance with typical ASTM, AMS, and Mil specifications:

Passivation of Stainless Steel to ASTM A967

Five nitric and citric methods are listed as follows:

Nitric 1: 20-25 v% Nitric Acid, 2.5 w% Sodium Dichromate, 120-130F, 20 Mins minimum

Nitric 2: 20-45 v% Nitric Acid, 70-90F, 30 Mins minimum

Nitric 3: 20-25 v% Nitric Acid, 120-140F, 20 Mins minimum

Nitric 4: 45-55 v% Nitric Acid, 120-130F, 30 Mins minimum

Nitric 5: Other combinations of temperature, time, and acid with or without accelerants, inhibitors or proprietary solutions capable of producing parts that pass the specified test requirements

Citric 4: Other temperature, time, and citric acid concentration combinations, with or without chemicals to improve cleaning, accelerants, or inhibitors, may be able to produce parts that are capable of passing the required test requirements.

Citric 5: Other temperature, time, and citric acid concentration combinations, with or without chemicals to improve cleaning, accelerants, or inhibitors, may be able to produce parts that are capable of passing the required test requirements. The pH of the immersion bath will be kept between 1.8 and 2.2.

Passivation Of Stainless Steel To AMS 2700

AMS 2700 covers passivation for both the nitric and citric methods.

Method 1 – Passivation in Nitric Acid (see types below)

Method 2- Passivation in Citric Acid (4-10w% Citric Acid, various temperature/time ratios are offered and additional wetting agents and inhibitors are acceptable)

The following types may be specified for Method 1:

Type 1 – Low temperature nitric acid with sodium dichromate (20-25v% nitric, 2-3w% sodium dichromate, 70-90F, 30 mins min)

Type 2 – Medium temperature nitric acid with sodium dichromate (20-25v% nitric, 2-3w% sodium dichromate, 120-130F, 20 mins min)

Type 3 – High temperature nitric acid with sodium dichromate (20-25v% nitric, 2-3w% sodium dichromate, 145-155F, 10 mins min)

Type 4 – 40v% nitric acid for free machining steels (38-42v% nitric, 2-3w% sodium dichromate, 70-120F, 30 mins min)

Type 5 – Anodic, for high carbon martensitic steels (20-25v% nitric, 2-3w% sodium dichromate, 70-90F, 2 mins min, part anodic at 3-5 volts)

Type 6 – Low temperature nitric acid (25-45v% nitric, 70-90F, 30 mins min)

Type 7 – Medium temperature nitric acid (20-25v% nitric, 120-140F, 20 mins min)

Type 8 – Medium temperature, high nitric acid concentration (45-55v% nitric, 120-130F, 30 mins min)

Passivation of Stainless Steel To QQ-P-35

QQ-P-35 does not cover citric acid passivation services. Four active nitric acid passivation services are covered as follows (four inactive methods have been withdrawn):

Type I – Withdrawn

Type II – 20-25 v% Nitric, 2-2.5 w% Sodium Dichromate, 120-130F, 20 Mins minimum

Type III – Withdrawn

Type IV – Withdrawn

Type V – Withdrawn

Type VI – 25-45 v% Nitric, 70-90F, 30 Mins minimum

Type VII – 20-25 v% Nitric, 120-150F, 20 Mins minimum

Type VIII – 45-55 v% Nitric, 120-130F, 30 Mins minimum

FAQs

Is passivation the same as pickling?

No. Passivation and pickling are two distinct techniques. To prepare stainless steel parts for passivation, the pickling procedure cleans the surface of welded parts of all debris, flux, and other contaminants. Steel cannot be protected from corrosion by pickling; pickling merely prepares the surface for the formation and functioning of the passivation layer.

Does passivation make stainless steel corrosion-proof?

A product cannot be completely corrosion-proof. The passivation process, however, gives stainless steel components an exceptionally long lifespan. Even though it is thin, the protective chromium layer can provide long-lasting protection, which you can even increase by giving the metal part regular maintenance and shielding it from oxidizing substances.

Is the passivation of stainless steel optional?

No, passivation is a necessary step for parts made of stainless steel. Without the procedure, your part will be vulnerable to corrosion attack in a very short amount of time.

Final Thoughts

Passivation is a crucial procedure that keeps stainless steel from corroding and keeps it looking brand new. Therefore, it is unquestionably an effective way to increase productivity and service quality.

Even though the procedure is straightforward, common passivation can be completed at home with a basic kit. You must work with a reputable business if you want production-grade stainless steel passivated parts.