Military Plating

Key Takeaways

- Stringent Standards Compliance: Valence Surface Technologies is dedicated to meeting and exceeding the rigorous standards required for military plating, ensuring every component delivers exceptional performance and reliability.

- Advanced Plating Solutions: Through continuous innovation and the development of advanced plating technologies, Valence offers tailored solutions that address the unique challenges of military applications, enhancing durability and operational readiness.

- Commitment to Sustainability: Discover the latest advancements and insights in military plating by check out our industry news.

In the demanding realm of defense applications, the integrity and performance of every component can make a critical difference. At Valence Surface Technologies, we understand that military plating is not just about enhancing the surface of a material; it’s about ensuring the utmost reliability, durability, and performance of defense equipment under the most rigorous conditions.

Our commitment to excellence in military plating is driven by a deep understanding of its significance—from adhering to stringent military specifications and standards to overcoming the unique challenges of corrosion, wear, and environmental impacts.

Discover how Valence can enhance your military hardware. Contact us today to explore our advanced plating technologies and services designed for the defense industry’s needs.

Key Requirements For Military Plating

In the defense sector, the functionality and longevity of military equipment are paramount. We are acutely aware that the foundation of exceptional military hardware lies in meeting and exceeding the rigorous standards set for military plating.

These standards ensure that components can withstand the extreme conditions they will face, from the depths of the ocean to the expanse of space.

Military Specifications And Standards

Compliance with military specifications (mil-spec) is non-negotiable. These detailed requirements ensure that every plated component offers the highest degree of reliability and performance. Our processes are meticulously designed to meet these standards, ensuring that every project we undertake is aligned with the critical needs of defense applications.

Adherence To Standards For Reliability

Reliability in the field is a matter of life and death. Our commitment to adhering to mil-spec standards is unwavering. Through rigorous testing and quality control, we guarantee that our plating solutions not only meet but exceed the expectations for durability, resistance, and overall performance. This commitment ensures that the military equipment serviced by Valence is ready for any challenge it might face.

At Valence, we don’t just see ourselves as a service provider; we are a partner in the defense sector’s mission to maintain the highest equipment readiness and reliability standards.

Advanced Plating Technologies For Defense Applications

With defense, the margin for error is nonexistent. At Valence Surface Technologies, we understand the critical nature of our role in ensuring that military hardware performs flawlessly under the most extreme conditions.

Tailored Solutions For Enhanced Performance

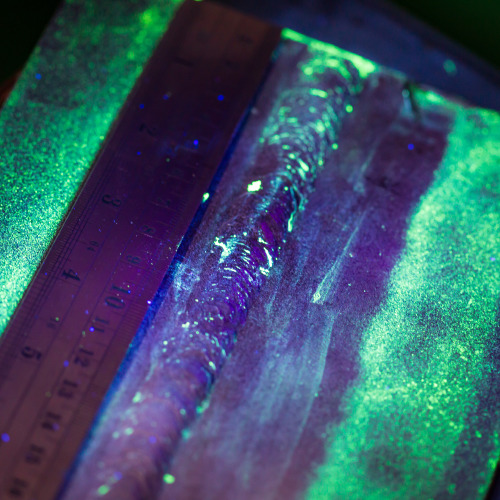

Our approach to military plating goes beyond conventional methods. We leverage a suite of advanced plating techniques, including but not limited to, proprietary electroplating processes, anodization for improved corrosion resistance, and specialized coatings that increase wear resistance and reduce friction. These tailored solutions are developed with one goal in mind: to enhance the performance and reliability of military components beyond the baseline requirements.

Meeting The Challenges Of Military Specifications

Compliance with military specifications is just the starting point. Our technologies are designed to address the unique challenges presented by defense applications, from environmental durability to operational longevity. Through continuous innovation and rigorous testing, we ensure that our plating services not only meet but exceed the stringent demands of the defense sector.

Our commitment to excellence ensures that the components we plate deliver unparalleled performance and reliability, ready to face the challenges of tomorrow’s defense landscape.

Ensuring Reliability And Performance

In defense, reliability isn’t just a goal; it’s a fundamental requirement. At Valence Surface Technologies, we’re not just meeting the expectations for military plating; we’re setting new standards for excellence.

Rigorous Testing And Quality Assurance

Every component that undergoes plating at Valence is subject to rigorous testing and quality assurance measures. Our processes are designed to ensure that each piece not only meets but exceeds the operational requirements it will face in the field. From stress tests to simulate extreme conditions to meticulous inspections for even the smallest imperfections, our commitment to quality is second to none.

Adapting To Evolving Defense Needs

The defense landscape is constantly evolving, and so are we. Our proactive approach to innovation means that the components we plate today are ready for the challenges of tomorrow, ensuring ongoing reliability and performance for critical defense missions.

Final Thoughts On Military Plating

As we’ve explored the critical role of military plating in ensuring the reliability and performance of defense equipment, it’s clear that the stakes could not be higher.

In the rapidly evolving landscape of defense technology, we remain committed to staying at the forefront of plating innovation. We understand that our work is crucial to the success of military operations, and we take this responsibility seriously. By continuously advancing our technologies and processes, we are proud to contribute to the enhanced performance and reliability of military hardware, supporting the critical missions of our defense partners.

Our solutions are designed to meet the stringent standards required for military applications, ensuring your equipment is mission-ready under any conditions.

Ready to enhance the durability and performance of your military hardware with advanced plating solutions? Contact us today to discover how our expertise can support your defense objectives.

Read Also:

- Chrome Coating: A Necessary Investment for Aerospace Components

- Amazon Kuiper: Everything You Need To Know

- Choosing The Right Finish: Anodizing Vs. Powder Coating

Frequently Asked Questions

What differentiates military plating from commercial plating?

Military plating adheres to more stringent standards for durability, corrosion resistance, and performance, as required by defense applications, whereas commercial plating may prioritize cost-efficiency and aesthetic qualities.

How does Valence ensure compliance with military specifications?

We employ rigorous testing, quality assurance processes, and adherence to the latest military specifications and standards to ensure every plating project meets the required compliance.

Can Valence handle high-volume military plating projects?

Yes, we are equipped with state-of-the-art facilities and a skilled team capable of handling high-volume projects without compromising on quality or adherence to specifications.

Does Valence provide solutions for corrosion resistance in marine environments?

Absolutely! We specialize in advanced plating techniques designed to enhance corrosion resistance, making them ideal for military hardware used in marine and coastal environments.

What is the turnaround time for a military plating project?

Turnaround times vary based on the project’s complexity and volume, but we are dedicated to meeting client timelines with efficient processes and project management.

Plating Services

Cadmium Plating

Cadmium plating is a tough and versatile coating. The soft, attractive coating provides a favorable bonding surface for adhesions. It is also the preferred plating for salt-water environments due to its resistance to mold and bacteria.

Chrome Plating

Chromium plating is effective at providing excellent hardness and lubricity, reducing friction, minimizing wear, and preventing galling. In environments with corrosion or abrasion, chrome plating can withstand negative consequences on wear and tear.

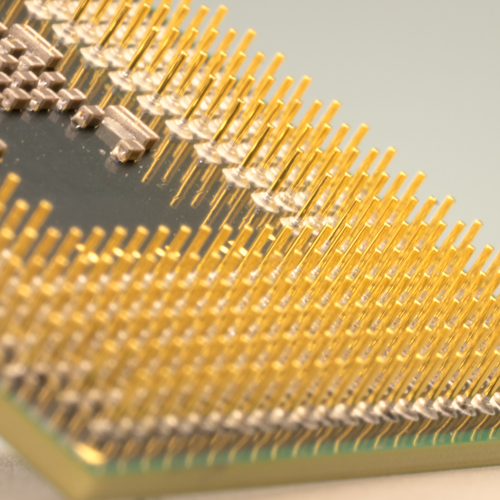

Gold Plating

Gold plating advantages include good corrosion resistance, good solderability, and, when alloyed with cobalt, it has very good wear resistance. Gold is commonly used in electrical switch contacts, connector pins and barrels, and other applications where intermittent electrical contact occurs. It is also used as a radiation shield, in infrared reflectors and satellite electronic housings. Valence also offers immersion gold plating.

Manganese Phosphate

Manganese phosphate coating is a conversion coating, the formulation of which contains a manganese salt, phosphoric acid and an accelerator. This process is done under high temperature, and produces a surface that has good corrosion and wear resistance. Manganese phosphate coatings can retain oil and other lubricants.

Nickel Sulfamate

Nickel sulfamate is a plating process that provides a highly ductile plating surface with low internal stress. The versatility of the coating resists high temperatures, maintains high tensile strength, and provides ductility and elongation.

Ti-Cad Plating

Ti-Cad or titanium cadmium plating is a titanium cadmium combination plating that provides corrosion resistance on high strength steel applications. It significantly reduces the negative consequences of hydrogen embrittlement.

Tin Plating

Tin plating is used extensively to protect both ferrous and nonferrous surfaces. Tin is also widely used in the electronics industry because of its ability to protect the base metal from oxidation and corrosion. Depending on the base material, tin is used as a metal plating to maintain or impart solderability. Valence also offers tin lead plating.

Valence performs all of these services to the highest degree of care, with approvals for most prime, aerospace, and military specifications. Our products and services significantly enhance safety, long-term use, and consistency in the aerospace industry. View our specs here.

Plating Tank Sizes

| Valence Wichita | L | Valence Garden Grove | L |

|---|---|---|---|

| Cadmium Types I, II, III | 4′ | Copper Plate | 2′ |

| Electroless Ni-Mid | 4′ | Electroless Ni- Hi Phos | 6′ |

| Electroless Ni-Hi Phos | 2.5′ | Electroless Ni- Low phos | 3′ |

| Hard Chrome | 14′ | Electroless Ni- Mid phos | 7.5′ |

| Hard Chrome | 7′ | Gold Immersion | 2′ |

| TiCad | 4′ | Gold Plate – Grade A Type lll | 2′ |

| Gold Plate – Grade C, Type II | 3.5′ | ||

| Gold Plate – Grade D, Type I, Type II | 1.5′ | ||

| Gold Strike | 3′ | ||

| Nickel Plate – Bright /Semi Bright | 4.5′ | ||

| Nickel Plate – Semi Bright | 4.5′ | ||

| Nickel Sulfamate | 4.5′ | ||

| Silver Plate – Semi Bright | 3.5′ | ||

| Sliver Plate – Matte | 5′ | ||

| Tin Plate | 4.5′ | ||

| Tin/Lead Plate (60/40) | 3′ | ||

| Tin/Lead Plate (90/10-95/5) | 2.5′ |

Plating News

Chrome Coating: A Necessary Investment for Aerospace Components

Chrome coating is not just a crucial investment, it's a necessity for aerospace components that are exposed to harsh conditions during flight. It offers a range of benefits, including enhanced durability, corrosion resistance, and improved performance. If you want to...

Gold Plating: The Best Way To Protect Aerospace Components From Tarnish

In the aerospace industry, the significance of gold plating cannot be overstated. This process plays a crucial role in safeguarding vital components against the detrimental effects of tarnish and corrosion. Unlike alternative plating techniques, gold plating stands...

Understanding The Different Types Of Gold Plating

Gold plating serves as a renowned metal finishing strategy that incorporates a delicate gold layer onto a metal object's surface. This gold veneer delivers an array of advantages such as augmented corrosion resistance, superior electrical conductivity, enhanced heat...

Choosing The Right Finish: Anodizing Vs. Powder Coating

Choosing the appropriate finish for a project, such as anodizing or powder coating, can present quite a challenge. Both of these finishes have distinct advantages and considerations, making it crucial to fully grasp their unique characteristics to guide your...