Chrome Plating Services

Chrome plating remains an integral process within various industries, prominently in aerospace and manufacturing, providing both visual and functional benefits. Skilled service providers like Valence Surface Technologies are imperative, understanding not only the intricacies of the process but the significant role that chrome plating services play in the innovation and maintenance of aerospace technology.

Valence Surface Technologies enhances your products with top-notch surface finishing. Contact us to elevate your products now!

What Is Chrome Plating?

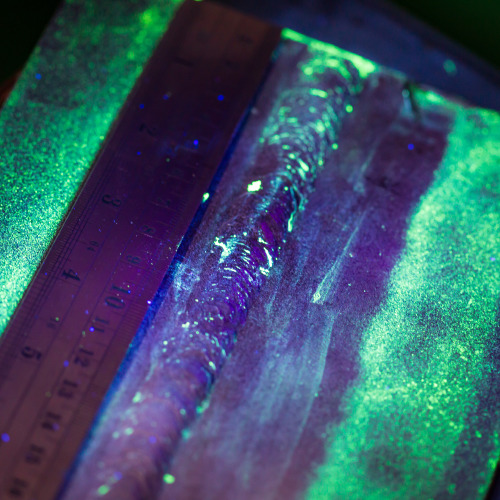

Chrome plating involves electroplating a thin layer of chromium onto an object, usually made of metal or plastic, to bestow a highly reflective finish and substantial resistance to corrosion and wear. This process is disproportionately crucial in the aerospace industry where the operational environment is unforgiving and the material integrity of components cannot be compromised.

Chromium plating doesn’t just protect; it enhances parts, ensuring they can withstand extreme conditions and perform consistently. In the world of aerospace, where precision and durability are non-negotiable, chrome plating transforms good components into outstanding, resilient ones. Valence Surface Tech excels in delivering this transformative service with impeccable precision and renowned expertise.

The Valence Edge In Chrome Plating

With a venerable history and a storied track record in chrome plating, Valence Surface Technologies exemplifies leadership through its commitment to quality, performance, and punctual delivery. Their extensive suite of services, including chrome plating, caters to the multifaceted needs of the aerospace and defense sectors, encompassing everything from intricate chemical processing to robust shot peening.

The breadth of Valence’s capabilities signifies their role as a comprehensive solutions provider, streamlining the supply chain for aerospace enterprises seeking reliability with a hint of simplicity. It is not just their services, but their extensive approval list—over 4,500 unique certifications—that further cement Valence as the preferred partner for industry leaders. In an industry where precision is paramount, Valence Surface Technologies’ chrome plating services are a beacon of assurance for customers who hold quality in the highest regard.

Chrome Plating Techniques And Technologies

When delving into chrome plating techniques and technologies, it’s important to understand the various methods and innovations in this field. Key areas to focus on include:

Techniques Advanced By Valence Surface Technologies

Innovation and continuous improvement underpin Valence’s approach to chrome plating. The company leverages state-of-the-art techniques and technologies to align with the stringent requirements and specifications inherent in aerospace and defense applications. It is their dedication to advancement that enables them to maintain an extensive list of approvals, each a testament to their competency and compliance with industry standards.

Valence’s expertise ensures that every chrome plating job, no matter how complex, adheres to the highest levels of precision and quality. Their unparalleled attention to detail is what instills confidence in clients who require nothing short of excellence in every plated component.

Embracing Green Processes

Valence Surface Technologies recognizes the importance of sustainability in plating processes, actively pursuing environmentally friendly practices without compromising quality. By minimizing waste and adhering to strict environmental standards, Valence aligns its operations with the growing demand for green technologies in industrial processes. Their commitment to environmental stewardship is an integral aspect of their service offering, resonating with clients who value responsible manufacturing practices.

As the aerospace industry leans towards sustainable innovation, Valence leads the way with chrome plating solutions that are as considerate of the planet as they are of performance. This progressive mindset towards environmental care secures Valence Surface Technologies role as a future-facing leader in the finishing services industry.

Types Of Metals Suitable For Chrome Plating

When considering the types of metals suitable for chrome plating, it’s important to recognize that not all metals are equally amenable to this process. Here are some commonly used metals and their suitability for chrome plating:

Steel

Steel, renowned for its robustness and remarkable structural integrity, is an exceptional choice for chrome plating. Its innate strength combines seamlessly with chrome layers, ensuring a steadfast and premium finish, thereby establishing itself as a reliable option for various applications across industries.

Aluminum

Aluminum, despite its non-ferrous nature, undergoes a transformative process with chrome plating. With an initial zincate step, it embraces chrome plating’s advantages, shielding itself against oxidation and elevating its overall aesthetic appeal. This fusion not only safeguards aluminum but also enhances its visual allure.

Copper

The allure of copper lies in its natural conductivity, rendering it a captivating choice for chrome plating. This becomes particularly evident in applications necessitating both electrical conductivity and the protective attributes of chrome. The melding of these qualities makes copper an ideal substrate for diverse industrial purposes.

Brass

Brass fixtures find a harmonious union with chrome plating, not solely for the purpose of enhancing their resilience against corrosion, but also for the contemporary charm it imparts. This amalgamation of durability, corrosion resistance, and modern aesthetics makes chrome-plated brass fixtures a sought-after choice in both commercial and residential settings.

Stainless Steel

Stainless steel, revered for its inherent corrosion-resistant properties, experiences an added layer of defense through chrome plating. This augmentation further fortifies its surface against corrosive elements, while concurrently providing a visually appealing, reflective sheen that enhances its allure in various applications and environments.

Applications And Industries Utilizing Chrome Plating

Chrome plating is widely used across various applications and industries due to its aesthetic appeal and protective qualities. Here are some of the key areas where chrome plating is extensively utilized:

Automotive Industry

The automotive industry has long capitalized on chrome plating for its dual ability to provide parts with a decorative finish and a durable, long-lasting surface. From trim and bumpers to engine components and exhaust pipes, chrome plating serves to enhance both the performance and the aesthetic of vehicles.

Automotive manufacturers value chrome for its corrosion resistance, contributing to the longevity of exterior and under-the-hood components alike. The lustrous appeal of chrome-plated elements on vehicles continues to be in demand, signifying luxury and attention to detail. Consequently, chrome plating has become a staple in automotive design and functionality.

Aerospace And Defense

The aerospace and defense industries demand that components can withstand extreme stresses and environmental conditions, which is precisely where chrome plating excels. It serves not only to fortify parts against wear and corrosion but also to improve their performance and ensure their reliability.

These attributes are essential in applications that range from aircraft engines to satellite components, where failure is not an option. Chrome plating contributes to the innovation and advancement of technology within these fields by extending the operational lifespan of critical components. The protective qualities provided by chrome plating assure consistent performance in some of the most demanding contexts found in aerospace and defense.

Home And Consumer Products

Beyond industrial applications, chrome plating finds considerable use in consumer products, enhancing the durability and visual appeal of items ranging from kitchen faucets to electronics. Its resistance to wear and ease of cleaning make it a favorite in the manufacturing of household items that see frequent use.

The luxurious sheen of chrome is synonymous with high-quality craftsmanship, increasing the value perception among consumers. Manufacturers across various sectors choose chrome plating for its blend of practical benefits and aesthetic elegance. Thus, chrome-plated consumer products are prevalent in homes, enhancing both the functionality and style quotient of everyday objects.

Benefits Of Chrome Plating

The benefits of chrome plating are numerous, making it a popular choice across various industries. Here are some of the key advantages:

Durability: Chrome plating adds a protective layer to the substrate that is capable of withstanding corrosion, wear, and tear, thus extending the lifespan of the component.

Aesthetic Appeal: The mirror-like finish that chrome plating achieves is highly desirable for both consumer goods and industrial components, enhancing the visual appeal of the object.

Increased Hardness: The hard chrome plating process increases the hardness of the substrate, making it more resistant to abrasion and wear.

Ease of Cleaning: Chrome’s smooth surface is easier to clean and less likely to harbor bacteria and dirt, making it ideal for applications requiring sanitary conditions.

Maintenance And Care For Chrome-Plated Surfaces

Maintaining and caring for chrome-plated surfaces is essential to preserve their appearance and longevity. Here are some effective steps to ensure proper upkeep:

Regular Cleaning: To maintain the integrity and appearance of chrome-plated surfaces, regular cleaning with a soft cloth and mild cleaning agents is recommended while avoiding harsh chemicals that could damage the finish.

Protect from Extreme Conditions: Chrome-plated items should be shielded from extreme temperatures and environmental conditions that could compromise the plating, meaning outdoor applications may require additional protective measures.

Use Appropriate Polishing Techniques: Maintaining the bright sheen of chrome can be achieved with approved non-abrasive polishes and polishing techniques suited for chrome, ensuring a lasting luster without scratching the surface.

Address Damage Promptly: Any damage to the chrome plating should be promptly attended to by a professional, as neglected blemishes can lead to peeling or further corrosion of the underlying metal.

Follow Manufacturer Guidelines: Adherence to the care instructions provided by the manufacturer of the chrome-plated product will ensure the best maintenance approach, tailored to the specific type of chrome plating and its intended use.

Why Choose Valence Surface Tech For Chrome Plating?

Choosing Valence Surface Technologies for chrome plating involves considering several key factors that distinguish their services in the industry. Here are compelling reasons to opt for Valence Surface Tech for your chrome plating needs:

Quality And Capacity Unmatched

Valence offers an unmatched level of expertise with a large capacity for processing and significant investments in its facilities and equipment. Their commitment to quality service and timely delivery is woven into the fabric of their operation, satisfying customers across commercial aviation, space communications, medical/life sciences, and more.

Customized Solutions For Your Unique Needs

Understanding that each project has its distinct challenges, Valence prides itself on providing scalable, custom solutions. They grow alongside their clients’ businesses, ensuring that as the demands and complexities evolve, so do the services and support offered by Valence.

A Partner In Progress

Choosing Valence Surface Technologies for your chrome plating needs means more than just acquiring a service—it’s about creating a partnership with a leader in aerospace product finishing. Their assured, confident, and professional delivery, coupled with an inspirational vision for the future of technology, positions them not just as a provider, but as a partner in the ever-expanding universe of aerospace and technology.

Final Thoughts On Chrome Plating

Chrome plating transcends being a mere surface enhancement; it serves as a linchpin in fortifying and propelling the industries integral to our daily lives. Valence Surface Tech isn’t just a service provider; it’s a committed partner dedicated to pioneering excellence, fostering innovation, and envisioning a future where impeccable finishing touches redefine the boundaries of every aerospace endeavor.

With an unwavering dedication to pushing industry standards, Valence embodies a relentless pursuit of excellence, constantly innovating with cutting-edge techniques and technologies to elevate chrome plating, catalyzing advancements across diverse industries. Embracing this vision, we strive for a future where meticulous attention to detail and unparalleled finishing optimize the performance, longevity, and reliability of every aerospace component, igniting progress and innovation across the spectrum of industries we serve.

Frequently Asked Questions About Chrome Plating

What is chrome plating?

Chrome plating is a technique of electroplating a thin layer of chromium onto a metal object. Chromium is a hard, durable, and corrosion-resistant metal that can give a product a bright, shiny finish. Chrome plating is used for both decorative and functional purposes.

What are the benefits of chrome plating?

There are many benefits to chrome plating, including:

- Improved appearance: Chrome plating can give a product a bright, shiny finish that is pleasing to the eye.

- Increased durability: Chrome plating can make a product more durable and resistant to wear and tear.

- Enhanced corrosion resistance: Chrome plating can protect a product from corrosion, rust, and other forms of oxidation.

- Reduced friction: Chrome plating can reduce friction, making a product smoother and easier to use.

- Easier cleaning: Chrome plating can make a product easier to clean and maintain.

What are the applications of chrome plating?

Chrome plating is used in a wide variety of applications, including:

- Automotive industry: Chrome plating is used on many automotive parts, such as bumpers, wheels, and trim.

- Household appliances: Chrome plating is used on many household appliances, such as stoves, refrigerators, and toasters.

- Furniture: Chrome plating is used on some furniture, such as lamps, tables, and chairs.

- Machinery: Chrome plating is used on some machinery parts, such as gears, shafts, and bearings.

- Aerospace: Chrome plating is used on some aerospace parts, such as landing gear and engine components.

How much does chrome plating cost?

The cost of chrome plating depends on a number of factors, including the size and shape of the item being plated, the type of chrome plating being used, and the desired finish. In general, chrome plating is a relatively inexpensive process.

Where can I find chrome plating services?

There are many chrome plating services available. You can find a chrome plating service in your area by searching online or asking for recommendations from friends or family.

What is the process of chrome plating?

The process of chrome plating involves several steps, including:

- Cleaning: The item to be plated is cleaned to remove any dirt, grease, or other contaminants.

- Pickling: The item is pickled in an acid solution to remove any rust or oxidation.

- Rinsing: The item is rinsed with water to remove the acid solution.

- Electroless nickel plating: The item is plated with a thin layer of nickel to provide a base for the chrome plating.

- Rinsing: The item is rinsed with water to remove the nickel plating solution.

- Chrome plating: The item is plated with a thin layer of chromium.

- Rinsing: The item is rinsed with water to remove the chromium plating solution.

- Drying: The item is dried to remove any moisture.

What materials can be chrome plated?

Chrome plating can be applied to a variety of materials, including:

- Steel: Steel is the most common material that is chrome plated.

- Aluminum: Aluminum can also be chrome plated, but it requires a special pretreatment.

- Plastic: Some plastics can be chrome plated, but it is a more difficult process than plating metal.

- Copper alloys: Copper alloys, such as brass and bronze, can be chrome plated.

- Zinc alloys: Zinc alloys, such as pot metal, can be chrome plated.

What are the different types of chrome plating?

There are two main types of chrome plating:

- Decorative chrome plating: Decorative chrome plating is used to improve the appearance of a product. It is typically a thin layer of chromium that is applied over a nickel base.

- Hard chrome plating: Hard chrome plating is used to increase the durability of a product. It is a thicker layer of chromium that is applied without a nickel base.

How long does chrome plating take?

The amount of time it takes to chrome plate an item depends on the size and shape of the item and the desired finish. In general, the process can take anywhere from a few hours to a few days.

What is the difference between hard chrome plating and decorative chrome plating?

Hard chrome plating is a thicker layer of chromium that is applied without a nickel base. It is used to increase the durability of a product. Decorative chrome plating is a thin layer of chromium that is applied over a nickel base. It is used to improve the appearance of a product.

Sources:

- American Electroplaters and Surface Finishers Society (AESF). (2023). Chrome plating. Retrieved from https://www.finishing.com/aesf/

- ASM International. (2023). Electroplating. Retrieved from https://www.asminternational.org/self-study-courses/results/-/journal_content/56/10192/1961586/CLASS/

- Chrome Plating Services. (2023). What is chrome plating? Retrieved from https://www.uschrome.com/finishes/

- Chrome Plating Solutions. (2023). Benefits of chrome plating. Retrieved from https://drgalva.net/Chrome-plating-solution-chrome-plating-for-home

- Chrome Pro Plating. (2023). Applications of chrome plating. Retrieved from https://chromeprosplating.com/

- Chrome X Plating. (2023). Chrome plating process. Retrieved from https://www.finishing.com/faqs/chrome.shtml

- Industrial Chrome Plating. (2023). Materials that can be chrome plated. Retrieved from https://www.industrialchrome.com/index.php/company

- National Center for Manufacturing Sciences (NCMS). (2023). Chrome plating. Retrieved from https://www.ncms.org/

- Precision Chrome Plating. (2023). Types of chrome plating. Retrieved from https://www.crcchrome.com/home.htm

- Surface Technology, Inc. (2023). Chrome plating FAQs. Retrieved from https://www.surfacetechnology.com/

Plating Services

Cadmium Plating

Cadmium plating is a tough and versatile coating. The soft, attractive coating provides a favorable bonding surface for adhesions. It is also the preferred plating for salt-water environments due to its resistance to mold and bacteria.

Chrome Plating

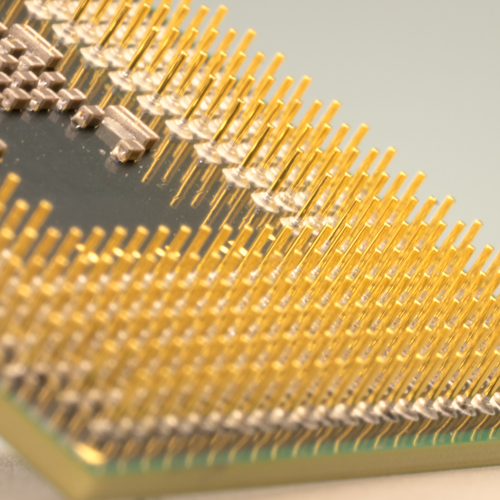

Chromium plating is effective at providing excellent hardness and lubricity, reducing friction, minimizing wear, and preventing galling. In environments with corrosion or abrasion, chrome plating can withstand negative consequences on wear and tear.

Gold Plating

Gold plating advantages include good corrosion resistance, good solderability, and, when alloyed with cobalt, it has very good wear resistance. Gold is commonly used in electrical switch contacts, connector pins and barrels, and other applications where intermittent electrical contact occurs. It is also used as a radiation shield, in infrared reflectors and satellite electronic housings. Valence also offers immersion gold plating.

Manganese Phosphate

Manganese phosphate coating is a conversion coating, the formulation of which contains a manganese salt, phosphoric acid and an accelerator. This process is done under high temperature, and produces a surface that has good corrosion and wear resistance. Manganese phosphate coatings can retain oil and other lubricants.

Nickel Sulfamate

Nickel sulfamate is a plating process that provides a highly ductile plating surface with low internal stress. The versatility of the coating resists high temperatures, maintains high tensile strength, and provides ductility and elongation.

Ti-Cad Plating

Ti-Cad or titanium cadmium plating is a titanium cadmium combination plating that provides corrosion resistance on high strength steel applications. It significantly reduces the negative consequences of hydrogen embrittlement.

Tin Plating

Tin plating is used extensively to protect both ferrous and nonferrous surfaces. Tin is also widely used in the electronics industry because of its ability to protect the base metal from oxidation and corrosion. Depending on the base material, tin is used as a metal plating to maintain or impart solderability. Valence also offers tin lead plating.

Valence performs all of these services to the highest degree of care, with approvals for most prime, aerospace, and military specifications. Our products and services significantly enhance safety, long-term use, and consistency in the aerospace industry. View our specs here.

Plating Tank Sizes

| Valence Wichita | L | Valence Garden Grove | L |

|---|---|---|---|

| Cadmium Types I, II, III | 4′ | Copper Plate | 2′ |

| Electroless Ni-Mid | 4′ | Electroless Ni- Hi Phos | 6′ |

| Electroless Ni-Hi Phos | 2.5′ | Electroless Ni- Low phos | 3′ |

| Hard Chrome | 14′ | Electroless Ni- Mid phos | 7.5′ |

| Hard Chrome | 7′ | Gold Immersion | 2′ |

| TiCad | 4′ | Gold Plate – Grade A Type lll | 2′ |

| Gold Plate – Grade C, Type II | 3.5′ | ||

| Gold Plate – Grade D, Type I, Type II | 1.5′ | ||

| Gold Strike | 3′ | ||

| Nickel Plate – Bright /Semi Bright | 4.5′ | ||

| Nickel Plate – Semi Bright | 4.5′ | ||

| Nickel Sulfamate | 4.5′ | ||

| Silver Plate – Semi Bright | 3.5′ | ||

| Sliver Plate – Matte | 5′ | ||

| Tin Plate | 4.5′ | ||

| Tin/Lead Plate (60/40) | 3′ | ||

| Tin/Lead Plate (90/10-95/5) | 2.5′ |

Plating News

Chrome Coating: A Necessary Investment for Aerospace Components

Chrome coating is not just a crucial investment, it's a necessity for aerospace components that are exposed to harsh conditions during flight. It offers a range of benefits, including enhanced durability, corrosion resistance, and improved performance. If you want to...

Gold Plating: The Best Way To Protect Aerospace Components From Tarnish

In the aerospace industry, the significance of gold plating cannot be overstated. This process plays a crucial role in safeguarding vital components against the detrimental effects of tarnish and corrosion. Unlike alternative plating techniques, gold plating stands...

Understanding The Different Types Of Gold Plating

Gold plating serves as a renowned metal finishing strategy that incorporates a delicate gold layer onto a metal object's surface. This gold veneer delivers an array of advantages such as augmented corrosion resistance, superior electrical conductivity, enhanced heat...

Choosing The Right Finish: Anodizing Vs. Powder Coating

Choosing the appropriate finish for a project, such as anodizing or powder coating, can present quite a challenge. Both of these finishes have distinct advantages and considerations, making it crucial to fully grasp their unique characteristics to guide your...