Dry Film Lubricant

In the quest for smarter, safer, and more reliable machinery and components, the introduction of dry film lubricants has brought a revolutionary shift in various industries. Dry film lubricant is a critical element that facilitates the smooth functioning of machinery without the mess or environmental concern associated with traditional lubrication methods.

Valence Surface Technologies takes pride in leading the charge by providing state-of-the-art dry film lubricant solutions that ensure peak performance in some of the most demanding applications across aerospace, medical, defense, and more.

What Is Dry Film Lubricant?

Understanding the basics of dry film lubricant is essential in appreciating its value across various industries. Unlike traditional lubricants, dry film variants provide a layer of lubrication between surfaces without the need for a liquid medium. This solid film acts to reduce friction, prevent wear and tear, and enhance the durability of components in mechanisms that are subjected to extreme conditions.

Why Does The Aerospace Industry Rely On Dry Film Lubricants?

Aerospace applications demand the utmost reliability and safety. Dry film lubricants play a critical role here, maintaining their properties at extreme temperatures and pressures while being space and weight-efficient. For aerospace manufacturers and operators, Valence Surface Technologies precision-applied dry film lubricants mean enhanced performance and dependability of critical aerospace components.

The Role Of Dry Film Lubricant In Commercial Aviation Maintenance

Commercial aviation maintenance is a critical field where safety, reliability, and precision are not just desired but required. Dry film lubricants contribute significantly to meeting these requirements, through several key applications.

Ensuring Reliability In Harsh Conditions

The ability of dry film lubricants to withstand extreme temperatures and resist corrosion makes them essential for aircraft that routinely face harsh environmental conditions. Each product from Valence is thoughtfully engineered and rigorously tested to perform without compromise, ensuring that the most sensitive aircraft components are safeguarded against the varied threats posed by different environments and weather patterns.

Reducing Maintenance Frequency And Costs

By using Valence dry film lubricants, airlines can reduce the frequency of maintenance. The longevity provided by these specialist lubricants not only keeps components operational for longer periods but also translates into a lower total cost of ownership. This is highly appreciated in the competitive aviation industry where efficiency and cost-effectiveness are direct contributors to the bottom line.

Enhancing Component Lifetime And Safety

The application of dry film lubricants directly impacts the lifespans of vital components. Solutions by Valence leverage high-performance materials that integrate seamlessly with parts to reduce wear and tear. This protective layer effectively extends component lifespan, thereby safeguarding both the integrity of the aircraft and the safety of its passengers.

Streamlining Compliance With Aviation Standards

Compliance with aviation standards is non-negotiable, and Valence dry film lubricants help ensure that each treated component adheres to rigorous industry regulations. By aligning their products with the latest and most stringent aviation specifications, Valence bolsters clients’ confidence that their operations consistently uphold the unparalleled safety that air travel demands.

Securing Equipment With Dry Film Lubricant For Military And Defense

In the military and defense sector, equipment reliability can be a matter of national security. Dry film lubricants play an indispensable role in ensuring that defense equipment operates flawlessly.

Enhancing Operational Readiness

Valence dry film lubricants are specifically engineered to sustain the superior performance of defense equipment by remaining effective in diverse climates and harsh conditions. This adaptability is vital for maintaining consistent operational readiness and ensuring that military assets are always mission-capable, regardless of the environment they’re deployed in.

Supporting Equipment Longevity In The Field

When military equipment is deployed, prolonged sustainability in the field is imperative. Dry film lubricants from Valence are not only robust and reliable but also uniquely formulated to prevent the common causes of equipment degradation. As a result, they play an essential role in preserving the functionality and extending the operational life of vital defense tools and vehicles, reducing the need for frequent servicing even amidst the rigors of combat or remote deployment challenges.

Providing Non-Detectable Lubrication Solutions

Sometimes what cannot be seen or heard makes all the difference. Valence non-detectable lubrication solutions are crucial in scenarios where stealth and non-visibility are paramount. These lubricants are expertly developed to ensure that they leave no discernible signatures, thus enabling military equipment to perform covert operations without the risk of detection that can be associated with traditional lubrication products.

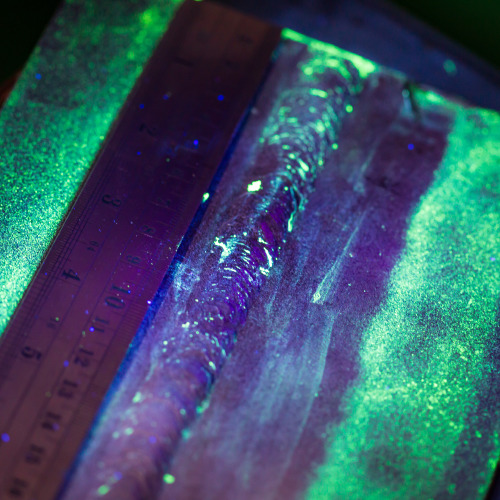

The Benefits Of Choosing Dry Film Lubricants For Surface Finishing

Dry film lubricants aren’t just about reducing friction; they also play an important role in surface finishing by providing a clean, durable, and often aesthetic coating that protects and improves the surface quality of parts.

Superior Protection Against Corrosion

Dry film lubricants from Valence provide superior protection against corrosion, creating a formidable barrier that shields components from moisture, chemicals, and other corrosive elements. This advanced level of protection significantly prolongs the functional integrity and aesthetic appeal of parts, ensuring they can withstand harsh operational environments without succumbing to the damaging effects of corrosion.

Consistency In Coating Application

Achieving a uniform coat is critical, and Valence has perfected the application process to deliver consistent and even layers of dry film lubricants. This meticulous approach guarantees that every surface finished by Valence has the same high-quality standards, reflecting a commitment to excellence that resonates across all provided services.

Maintaining Environmental Safety Standards

In today’s eco-conscious industrial landscape, Valence environmentally friendly formulations of dry film lubricants stand out. Complying with the strictest environmental safety standards, these lubricants support the sustainable initiatives of our clients, offering peace of mind that their environmental footprint is minimized without ever sacrificing the lubricant’s effectiveness or the component’s performance.

Aesthetic Versatility In Finishes

Valence understands that the visual aspect of a component can be just as important as its functionality. Therefore, they offer dry film lubricants with a range of finish options to suit various aesthetic preferences. Whether the requirement is for a glossy, matte, or textured finish, Valence has the capability to customize solutions to align with the product’s design and customer expectations, adding a finishing touch that complements both form and function.

Custom Dry Film Lubricant Solutions For Unique Aerospace Needs

Every aerospace application has unique requirements, and sometimes, a one-size-fits-all solution doesn’t cut it. Valence is equipped to tailor dry film lubricant formulations that align precisely with specific operational needs, ensuring that performance, compliance, and durability are at the forefront of every custom solution.

Valence Expertise In Dry Film Lubricant Services

With years of experience and a dedicated team of specialists, Valence stands at the forefront of dry film lubricant services. Their expertise is evident in the comprehensive range of services they offer.

Industry-Leading Application Techniques

Valence forward-thinking approach includes pioneering application methods that not only fulfill industry demands but set new standards for quality. By harnessing the latest in surface technology, Valence ensures each application of dry film lubricant is performed with the utmost accuracy, resulting in unparalleled surface treatments that serve as benchmarks within the industry.

Precision-Driven Results

The dedicated team at Valence operates with a mindset where precision is not just an outcome; it’s a guiding principle. This attention to detail is reflected in how they expertly manage lubricant applications, thus ensuring that components in the most critical sectors, such as aerospace and medical devices, achieve the high level of performance expected of them, down to the minutest detail.

Scalable Solutions For Businesses Of All Sizes

Recognizing that each client has unique needs, Valence offers scalable dry film lubricant solutions, adapting effortlessly from small customized batches to large-volume runs with unwavering quality. This adaptability proves essential for businesses looking to grow, as they can rely on Valence to meet their evolving lubricant requirements without skipping a beat.

Continuous Research And Development

Unsatisfied with the status quo, Valence ongoing investment in research and development places them at the forefront of innovative surface treatments. Their relentless pursuit of the next breakthrough in dry film lubricant capabilities not only advances the field but ensures their clients have access to the most cutting-edge solutions on the market. With a finger always on the pulse of the latest surface technology trends, Valence is equipped to push boundaries in lubrication science, offering smarter and more effective solutions day by day.

How Valence Leads With Dry Film Lubricant Innovations

Innovation drives progress, and at Valence, it’s the heartbeat of their strategy in redefining the capabilities of dry film lubricants.

Pioneering New Formulations

At Valence, the exploration for next-level dry film lubricant formulations never ceases. Each new blend is an opportunity to enhance performance, overcome previous limitations, and unlock new applications. These efforts ensure that their clients are equipped with the most advanced lubrication solutions that the industry has to offer, reaffirming Valence’s position as a trailblazing force in technological advancements.

Customization For Next-Gen Applications

Aligning with the ever-shifting landscape of technological advancements, Valence stands ready to modify and adapt its lubricants for the cutting-edge requirements of next-generation applications. From creating specialized coatings that integrate with the latest aerospace designs to formulating lubricants that meet the precise demands of modern defense systems and medical devices, Valence is at the vanguard of custom solutions.

Setting Industry Benchmarks

By persistently raising the bar for what dry film lubricants can achieve, Valence not only meets industry benchmarks – it creates them. Their relentless drive to provide top-tier performance and quality assurance places their clients ahead of the curve, affording them unparalleled confidence in the reliability and superiority of their equipment and machinery, across all fields where precision is pivotal.

Why Choose Valence For Your Dry Film Lubricant Services?

When it comes to selecting a partner for dry film lubricant services, there are several key reasons to consider Valence.

A Proven Track Record Of Excellence

Valence’s longstanding reputation for excellence is rooted in a track record of success, reflecting their unwavering commitment to quality in the surface technology industry. With each project, Valence has consistently surpassed industry expectations, earning the trust of clients by delivering exceptional results that speak to their comprehensive understanding of surface treatment requirements and challenges.

Cutting-Edge Facilities And Processes

Through investment in cutting-edge facilities and the adoption of advanced processes, Valence provides services that are at the forefront of the industry, ensuring that clients receive nothing short of the best. These state-of-the-art resources enable Valence to maintain precise control over the application of dry film lubricants, resulting in consistent, high-quality outcomes that are tailored to clients’ specific needs.

A Commitment To Customer Satisfaction

At Valence, customer satisfaction forms the cornerstone of their business strategy. This commitment is evident in their proactive approach to customer service, where they work diligently to ensure a positive and fulfilling experience for each client, from the initial inquiry through to the completion of the service and beyond. This dedication to client contentment builds lasting relationships and establishes Valence as a reliable and trusted partner in the industry.

Leading With A Vision For The Future

Forward-thinking and future-ready, Valence not only meets the current needs of their clients but also positions them for success with forward-looking solutions that anticipate future industry developments. Their vision for the future is informed by a clear understanding of emerging trends, allowing Valence to lead the way in providing innovative solutions that address both present and imminent challenges. This foresight ensures that clients are always one step ahead, equipped with dry film lubricant services that evolve in tandem with the progressive landscape of their respective industries.

Final Thoughts

Dry film lubricants are the silent guardians within critical industries, essential for optimizing performance and extending the lifespan of vital machinery. Valence stands out as an industry leader, bringing innovative solutions that keep clients at the forefront of their fields. Their expertise in dry film lubricants is not just about supplying a product—it’s about crafting a competitive edge that propels businesses forward.

In a market that demands nothing less than excellence, choosing Valence for your dry film lubricant needs is a strategic move towards future success. Elevate your operations with their tailored solutions, where cutting-edge technology meets unwavering quality. Connect with Valence and embrace the next generation of surface innovation today.

Frequently Asked Questions About Dry Film Lubricant

How does dry film lubricant differ from traditional lubricants?

Dry film lubricants provide lubrication without the need for a liquid, offering reduced mess and environmental concerns compared to traditional lubrication methods.

What are the environmental benefits of Valence dry film lubricants?

They comply with strict environmental safety standards, minimizing environmental footprints without compromising effectiveness.

How customizable are the finishes offered by Valence dry film lubricants?

Valence offers a range of finish options, from glossy to matte or textured, catering to various aesthetic preferences.

How does Valence cater to unique aerospace needs with their lubricant solutions?

They provide custom formulations tailored precisely to specific operational requirements in aerospace applications.

What distinguishes Valence application techniques from others in the industry?

Valence employs industry-leading application methods that ensure accuracy and high-quality surface treatments.

Are Valence lubricant solutions scalable for different business sizes?

Yes, their solutions can adapt from small customized batches to large-volume runs without compromising quality.

What sets Valence apart in terms of continuous research and development?

They invest consistently in R&D, ensuring access to cutting-edge solutions and advancements in lubrication science.

How does Valence innovate in dry film lubricant formulations?

They continually develop new formulations to enhance performance, overcome limitations, and unlock new applications.

What differentiates Valence approach to customer satisfaction?

Their commitment to proactive customer service ensures a positive experience from inquiry to service completion.

What makes Valence a future-ready partner in dry film lubricant services?

Their understanding of emerging trends equips them to offer innovative solutions that address both present and future challenges.

Sources:

- Adhikari, S., & Sharma, M. M. (2021). Recent advancements in dry film lubricant coatings: A review. Progress in Organic Coatings, 153, 106150. https://link.springer.com/10.1007/978-3-642-22647-2_43

- Cao, Z., Zhao, H., Zhou, W., Zhang, X., & Li, L. (2022). Recent advances in environmentally friendly dry film lubricants: A review. Friction, 10(4), 665-697. https://link.springer.com/article/10.1007/s10853-012-7038-2

- Garg, A. K., Goyal, S., & Chauhan, R. M. (2020). Applications of dry film lubricants: A review. Materials Science for Engineering C, 110, 110684. https://www.sciencedirect.com/science/article/pii/0041267870902794

- Gupta, S., Bahadur, S., & Kapoor, S. (2018). Tribological properties of molybdenum disulfide based dry film lubricants: A review. Friction, 6(3), 251-282. https://www.sciencedirect.com/science/article/pii/0041267870902794

- Holmberg, K., & Erdemir, A. (2017). Influence of tribological films on friction and wear. Tribology International, 113, 163-174. https://www.sciencedirect.com/science/article/pii/B9780323907484000042

- Kapoor, A., & Kumar, S. (2021). Recent advancements in solid lubricant coatings for extreme environment applications: A review. Progress in Organic Coatings, 150, 106007. https://www.sciencedirect.com/journal/progress-in-organic-coatings

- Mishra, A., & Bahadur, S. (2016). Tribological performance of inorganic fullerene-like tungsten disulfide (IF-WS2) based dry film lubricants at elevated temperatures: A review. Tribology Letters, 62(3), 1-15. https://www.springer.com/journal/11249

- Neale, M. J., & Smith, J. H. (2016). Tribological properties of hexagonal boron nitride (hBN) films and coatings. Tribology Letters, 63(3), 1-13. https://www.springer.com/journal/11249

- Pawar, P., & Harsha, S. P. (2019). Recent advances in solid lubricant coatings for aerospace applications: A review. Progress in Aerospace Sciences, 108, 100527. https://www.sciencedirect.com/journal/progress-in-aerospace-sciences

- Wu, J., Wang, W., Zhang, H., & Xue, Q. (2018). Recent progress on the design and fabrication of superlubricity surfaces. Friction, 6(3), 123-140. https://www.sciencedirect.com/science/article/abs/pii/S016943322100458X

Painting Services

Primer

Primer, also known as undercoat, is the preparatory coating that can be used to enhance the bond strength of a topcoat and/or improve the corrosion resistance of a part. Applying primer is a crucial first step to the lasting results.

Fuel Tank Coating

Fuel tank coating is a specialty coating applied to the interior of aircraft fuel tanks that protects against corrosion from fuel contaminants. The coating allows fuel tanks to meet industry standards for longer durations.

Adhesive Bond Primer

Topcoat

Topcoat is the final coating on a part often used for cosmetic purposes. However, it often has application specific properties, such as reflectivity, conductivity, etc. The topcoat provides durability and resistance to harmful materials that will cause parts to deteriorate.

Anti-Chafe

Anti-Chafe topcoats are specific coatings that are primarily used on surfaces where abrasion resistance, low friction and impact resistance are required to reduce chafing and wear. This specific topcoat serves as a defense in harmful environments.

Dry Film Lube

Dry film lube is a dry lubricant coating that reduces friction on surfaces sliding against each other. It offers operation at higher temperatures than other lubricants.

Sol-Gel

Sol-Gel is a process of creating metal oxides when applied to a part using metal alkoxides. The sol-gel is in high demand as it allows adhesive bonding of titanium and corrosion resistant alloys.

Zinc Spray

Zinc spray, or zinc chromate spray is a primer with corrosion inhibiting properties, commonly used on aluminum aircraft or spacecraft components. It is a high quality aerospace plating technique.

Digital Masking

Valence performs all of these services to the highest degree of care, with approvals for most prime and military specifications. Our products and services significantly enhance safety, long-term use, and consistency in the aerospace industry. View our specs here.

Painting Capability Sizes

| Valence Eastman | L | Valence Wichita | L | Valence Grove | L | Valence Los Angeles | L | Valence Seattle | L | Valence Everett | L | Valence Garden Grove | L |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bond Primer | 20' | Bond Primer | 16' | Bond Primer | 24' | Bond Primer | 27' | Bond Primer | 6' | Bond Primer | 30' | Bond Primer | 10' |

| Dry Lube | 20' | Dry Lube | 16' | Dry Lube | 10' | Dry Lube | 27' | Dry Lube | 2.5' | Dry Lube | 30' | Paint | 10' |

| Fuel Tank Coating | 20' | Fuel Tank Coating | 16' | Fuel Tank Coating | 24' | Fuel Tank Coating | 27' | Fuel Tank Coating | 6' | Fuel Tank Coating | 30' | ||

| Primer | 20' | Primer | 16' | Primer | 24' | Primer | 27' | Prime and Topcoat | 6' | Primer | 30' | ||

| Topcoat | 20' | Sol Gel | 16' | Topcoat | 24' | Topcoat | 27' | Sol Gel | 4' | Topcoat | 30' | ||

| Sol Gel | 20' | Topcoat | 24' | Sol Gel | 24' | Sol Gel | 27' | Sol Gel | 30' | ||||

| Zinc Spray | 12' |

Painting & Spray Coating News

What Are Thermal Control Coatings (TCC) For Satellites?

As satellites venture through the unforgiving expanse of space, they face a formidable challenge: the extreme temperatures that fluctuate between scorching heat and icy cold. To conquer this cosmic thermal battleground, satellites enlist the aid of a remarkable ally:...

Thermal Control Coatings: A Necessary Component For Satellites

Discover why thermal control coatings are essential for safeguarding satellites against extreme temperatures and may guarantee their optimal performance…

Passivation Standards ASTM A967

Stainless steel, having found applications in different industries is an important part of our daily lives. In the aerospace and even many manufacturing industries, stainless steel has found application and is a very important material. It is known to have better...

What Is Passivation: The Secret To Long-Lasting Metal Protection

Understand the ABCs of passivation and learn how it extends the life of metal components by protecting them from corrosion and oxidation …