Hard Anodizing

Valence Surface Technologies provides Hard Anodize in

The most common specification is MIL-A-8625 Type

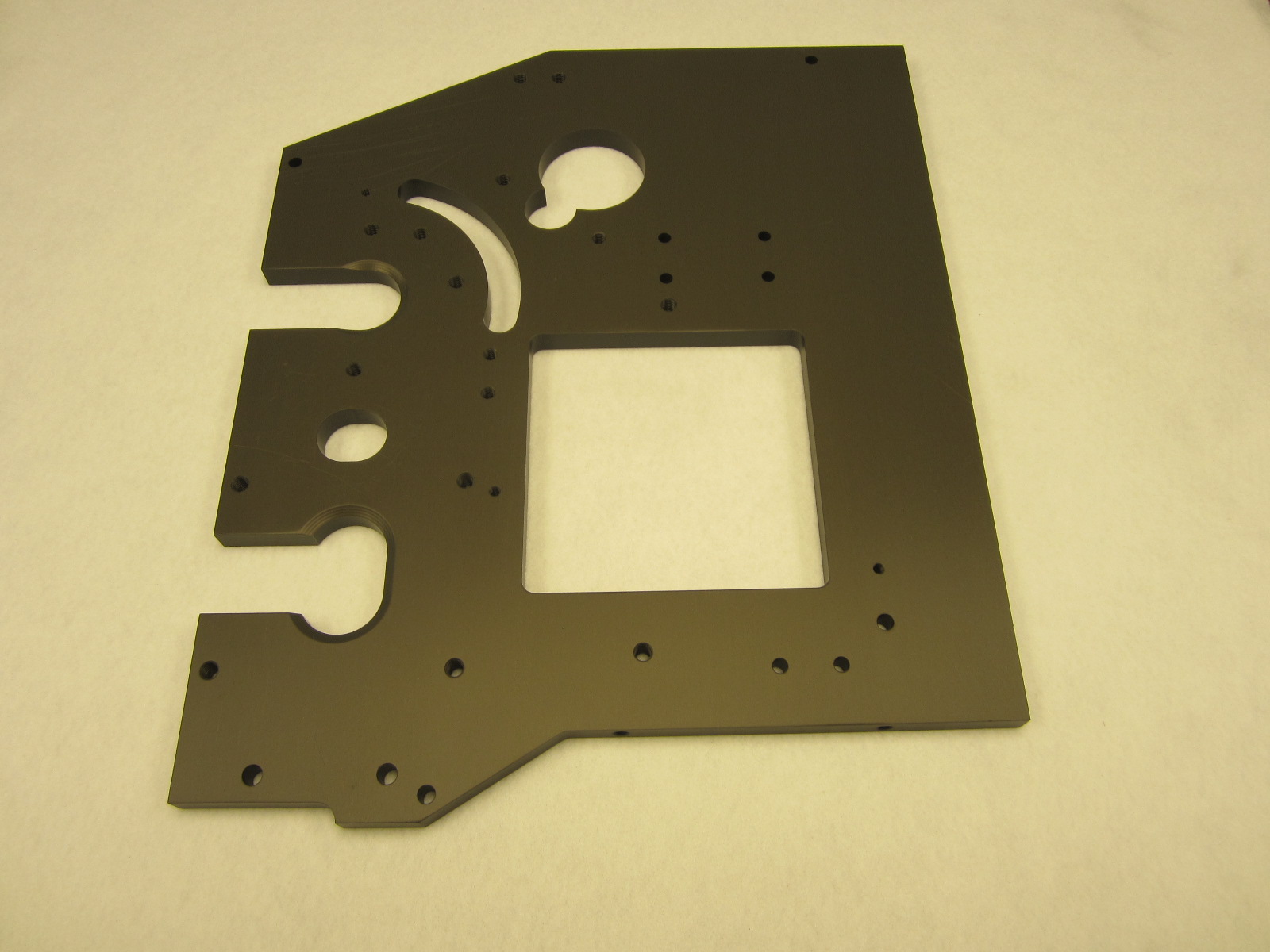

Hard anodizing is typically applied to heavy wear industrial parts intended for use in aggressive or highly corrosive applications. These coatings are typically far thicker and harder than decorative ones, and

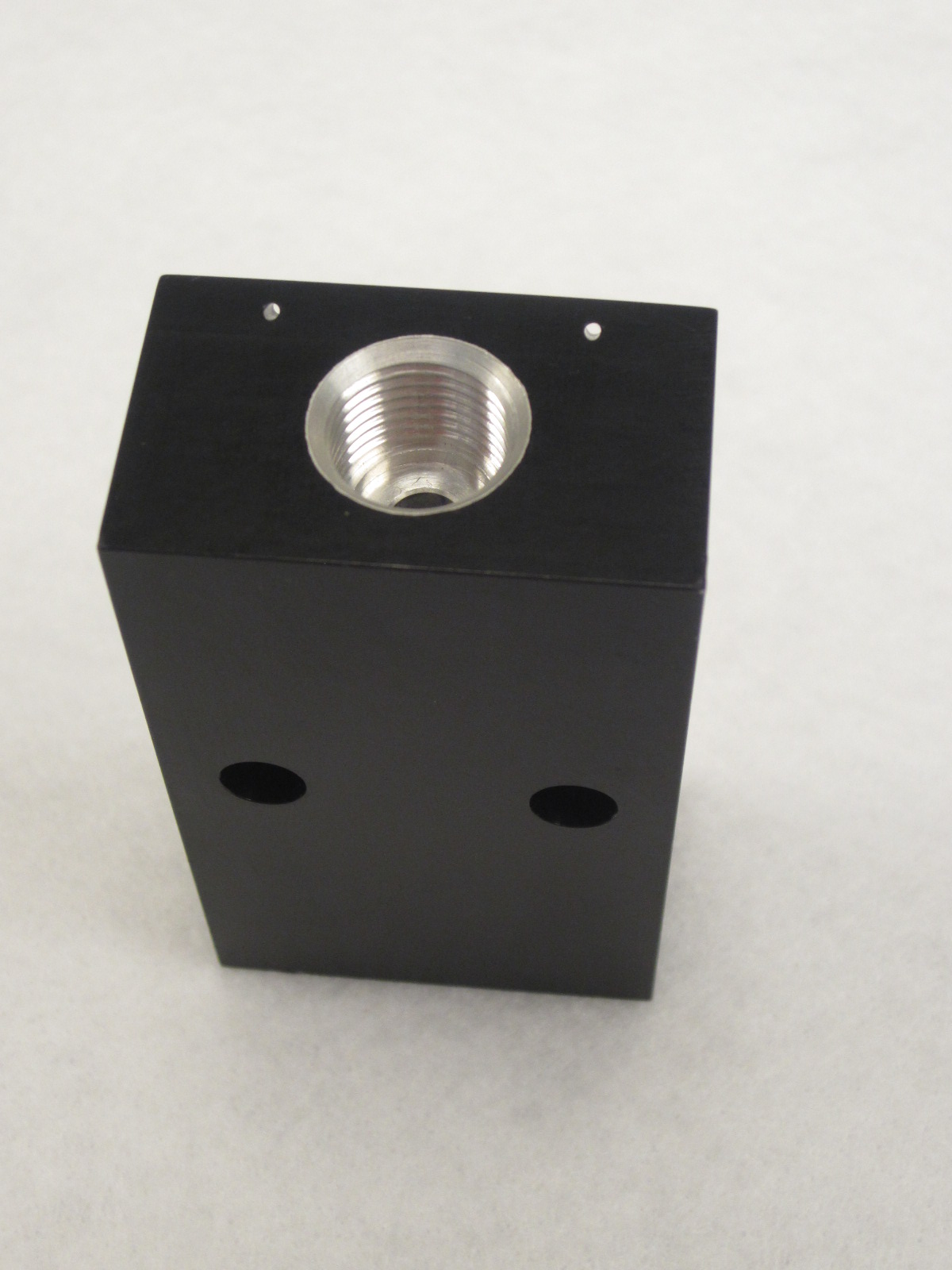

Hard coated items usually have a dark gray to a black finish. This can vary depending on the aluminum alloy.

Benefits of Hard Anodizing in Aerospace

One of the main purposes of hard anodizing is to make the aluminum more resistant to corrosion. The thicker oxidized layer protects the finished part from being exposed to moisture, oxygen, and other factors. Sealed items are even more corrosion resistant.

The outer coating is also extremely hard, typically much harder than the original metal. In many cases, a thick hard anodized coating can be as hard as tool steel.

The oxide layer is part of the metal, it won’t peel off, and the surface finish will increase. Hard anodized metals are usually very well insulated they don’t conduct heat or electricity well.

This is especially useful for applications that require the part be used at high temperatures.

Request a quote on sulfuric anodizing for your application, or contact us with any questions.

Hard

Black Hard Anodize Type