Valence Seattle

Employees

Square Footage

Processes

Processes

Parts Per Year

Processing Capabilities

NDT

Magnetic Particle

Penetrant

Painting / Coatings

Dry Lube

Fuel Tank Coating

Prime and Topcoat

Sol Gel

Additional Services

Glass Bead

Part Mark

Plastic Bead Blast

Shot Peen

Chemical Processing Aluminum

Anodize – Type II Sulfuric

Chemical Conversion Coating- Type 1 (Bonderite 1200)

Chemical Conversion Coating- Type 1 (Bonderite 600)

Chemical Processing Hard Metals

Passivate Type VI

Phosphate Fluoride

Titanium Etch (Pickle)

Significant

Approvals

Customer Portal

Valence Seattle News

Thermal Control Coatings: A Necessary Component For Satellites

Discover why thermal control coatings are essential for safeguarding satellites against extreme temperatures and may guarantee their optimal performance…

Valence Seattle Operations Offers NEW Anodizing: Black Dye Capabilities

SEATTLE, WA, FEBRUARY 08, 2021 - Valence Seattle successfully completed its expansion and has been offering Hard (Type III) Anodizing services for the aerospace and defense supply chain in the Pacific Northwest in September 2020. Valence Seattle is now offering Type...

Valence Seattle Operations Completes Expansion for NEW Hard Anodizing Capabilities

SEATTLE, WA, October 1, 2020 - Valence Seattle has successfully completed its recent expansion and is now offering hard anodizing services for the aerospace and defense supply chain in the Pacific Northwest. Valence’s Seattle operations has a long history of offering...

Valence gains Boeing approval for a new titanium etch processing line in the Pacific Northwest

EVERETT, Wash., April 16, 2018 – Valence Surface Technologies (Valence), the world’s largest independent provider of aerospace product finishing services, announced today that it has received Boeing approval for a new, state of the art titanium etch line at its plant...

Key Takeaways:

- Aerospace Precision Parts Expertise: Valence Seattle, formerly known as MAPSCO since 1981, excels in processing small to medium-sized precision parts for the aerospace industry. Their 35 years of experience in the Pacific Northwest positions them as leaders in the region.

- Commitment To Quality: Valence Seattle stands out for its unwavering commitment to on-time delivery, top-notch customer service, and quality assurance. Their emphasis on transparent communication, competitive turnaround times, and technical expertise set the industry standard.

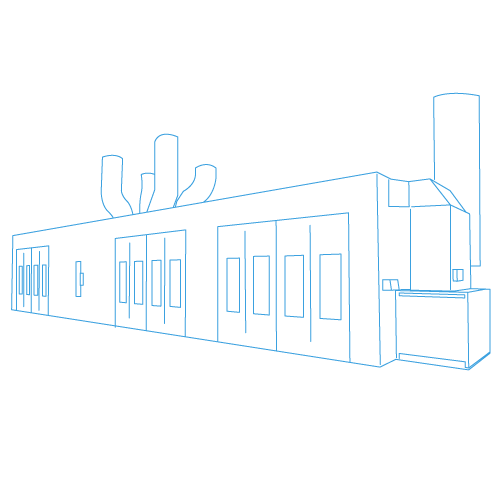

- Comprehensive Aerospace Services: Valence Seattle offers a 32,000-square-foot facility equipped with an array of services, including non-destructive testing (NDT), chemical processing, shot peening, and painting. It proudly supports leading aerospace manufacturers and processes over 4 million parts annually, showcasing its efficiency and state-of-the-art capabilities.

Welcome to Valence Surface Tech, your premier destination for aerospace finishing solutions in Seattle, Washington. As a full-service finishing company specializing in commercial aerospace, defense, space, and satellite industries, we understand the importance of precision and quality in aerospace finishing. In this article, we will delve into various aspects of aerospace finishing, offering technical insights and valuable information for companies seeking top-of-the-line surface finishing services.

Looking for precision and quality in aerospace finishing? Choose Valence Seattle, WA – your trusted partner in the Pacific Northwest! Contact us today for inquiries and a customized quote for your finishing solutions.

What Are Aerospace Finishing Companies?

Aerospace finishing companies in Seattle, Washington, are specialized businesses that offer comprehensive surface finishing solutions tailored to the needs of the aerospace, defense, space, and satellite industries. These companies provide a range of services aimed at enhancing the performance, durability, and safety of aerospace components and structures. Their expertise lies in applying various finishing techniques and coatings to aerospace materials, ensuring they meet industry-specific quality standards.

Unlock The Future Of Aerospace Excellence With Valence Surface TechnologiesExperience aerospace finishing like never before with Valence, the world’s leading independent aerospace product finishing company. We’re the only complete integrated solution serving the aviation, defense, and space industries.

Your journey to aerospace excellence begins with Valence. Contact us today for a comprehensive assessment of your finishing requirements. |

Importance Of Aerospace Finishing Companies

Aerospace finishing companies in Seattle play a crucial role in ensuring the reliability and safety of aerospace equipment. Their importance stems from several key factors:

- Enhanced Performance: Aerospace finishing enhances the performance of critical components, ensuring they can withstand extreme conditions and function optimally.

- Safety: Finishing processes improve the durability and reliability of aerospace parts, contributing to the safety of aircraft, spacecraft, and defense systems.

How Do Aerospace Finishing Companies Work?

Aerospace finishing companies in Seattle employ a systematic approach to enhance the quality and functionality of aerospace components.

- Surface Preparation: Thorough cleaning and preparation of the component’s surface to ensure proper adhesion of finishing materials.

- Coating Application: Applying specialized coatings, such as paints, primers, or platings, to protect against corrosion, abrasion, or other environmental factors.

- Quality Control: Rigorous quality control measures to verify the precision and consistency of finishing processes.

Benefits Of Aerospace Finishing Companies

Aerospace finishing companies in Seattle offer several benefits, including:

Improved Durability

Aerospace finishing processes enhance the lifespan of aerospace components by applying specialized coatings and treatments that protect against corrosion, abrasion, and environmental factors.

Enhanced Performance

Aerospace finishing optimizes the performance of components by improving aerodynamics, thermal properties, and functionality, leading to increased efficiency and effectiveness.

Compliance

Aerospace finishing companies adhere to industry-specific quality and safety standards, ensuring that finished products meet or exceed regulatory requirements, and instilling confidence in their reliability.

Cost-Efficiency

While aerospace finishing incurs initial costs, it ultimately reduces long-term expenses by preventing premature component failure, extending operational lifespans, optimizing performance, and minimizing the risk of defects or recalls.

Certifications Needed In Aerospace Finishing Companies

When it comes to aerospace finishing, certifications play a crucial role. Companies operating in this industry need to meet stringent quality and safety standards.

- AS9100 Certification: This quality management system certification is specific to the aerospace industry, ensuring compliance with industry-specific standards.

- NADCAP Certification: The National Aerospace and Defense Contractors Accreditation Program (NADCAP) ensures that aerospace finishing processes adhere to the highest quality and consistency standards.1

- ISO 9001 Certification: This globally recognized certification emphasizes quality management and continuous improvement in aerospace finishing processes.

Industries That Depend On Aerospace Finishing Services In Seattle

Aerospace finishing services in Seattle cater to a wide range of industries, including:

Commercial Aerospace

Commercial aerospace refers to the industry involved in the design, manufacturing, and operation of aircraft and related systems for non-military purposes. This sector includes the production of commercial airplanes, such as passenger and cargo aircraft, and services related to their maintenance and operation.

Defense

Defense, in the context of aerospace, pertains to the military and national security applications of aerospace technology. It encompasses the development and deployment of military aircraft, unmanned drones, and aerospace systems for purposes like surveillance, defense, and combat.

Space Exploration

Space exploration involves the scientific investigation and exploration of outer space beyond Earth’s atmosphere. This field encompasses missions to study celestial bodies, launch satellites, conduct research on space phenomena, and explore the potential for human presence in space, including missions to other planets and celestial bodies.

Satellite Communications

Satellite communications involve the use of artificial satellites orbiting Earth to transmit and receive signals for various purposes. This technology enables global communication, including television broadcasting, internet connectivity, navigation systems (GPS), and data transmission for businesses, governments, and individuals.

Quality Standards For Choosing An Aerospace Finishing Company

Selecting the right aerospace finishing company in Seattle is paramount. Consider the following quality standards:

- Experience: Aerospace finishing companies with a wealth of experience possess a deep understanding of the industry’s intricacies and have a proven track record in delivering high-quality finishing solutions. Their expertise is invaluable in ensuring precise and reliable finishing processes.

- Technical Capabilities: Technical capabilities refer to advanced equipment, state-of-the-art technology, and specialized techniques employed by aerospace finishing companies. These capabilities enable them to execute finishing tasks with precision, efficiency, and in compliance with industry standards.

- Quality Control Measures: Quality control measures involve rigorous processes and inspections implemented by aerospace finishing companies. These measures encompass testing, inspection, and documentation to ensure finished products meet or exceed specified quality criteria.

Got aerospace parts that need VIP treatment? We have you covered. Connect with us for inquiries and receive a quick, hassle-free quote tailored to your requirements.

Valence Surface Tech Distinctions In Seattle’s Aerospace Finishing Industry

At Valence Surface Tech, we pride ourselves on being a leader in Seattle’s aerospace finishing sector. Our distinctions include:

NADCAP And AS9100 Certifications

NADCAP (National Aerospace and Defense Contractors Accreditation Program) and AS9100 are critical certifications in aerospace finishing. NADCAP ensures that a company meets stringent industry-specific quality and performance standards, while AS9100 is a quality management system standard specific to the aerospace industry.2 These certifications demonstrate a company’s commitment to maintaining high-quality aerospace finishing processes.

Cutting-Edge Technology

Cutting-edge technology in aerospace finishing refers to the use of advanced and state-of-the-art machinery, materials, and techniques. This technology enables precision, efficiency, and the ability to meet the demanding requirements of aerospace projects, resulting in superior finishing outcomes.

Experienced Team

An experienced team in aerospace finishing comprises professionals with a deep understanding of the industry and a track record of successfully completing complex projects. These experts bring invaluable knowledge, skills, and insights to ensure the highest quality and consistency in finishing processes.

Customized Solutions

Customized solutions in aerospace finishing involve tailoring the finishing processes and techniques to meet the unique needs and specifications of each client or project. This approach ensures that the finishing services align perfectly with the client’s goals, resulting in optimized performance and quality.

Types Of Aerospace Companies In Seattle

While it’s challenging to provide an exact count due to the industry’s dynamic nature, the presence of major aerospace companies like Boeing, along with a robust supply chain, makes Seattle a hub for aerospace finishing expertise.

- Aircraft Manufacturers: Seattle is known for Boeing, one of the world’s leading aircraft manufacturers, which designs and manufactures commercial and military aircraft.3

- Aerospace Suppliers: The region hosts numerous aerospace suppliers that provide components, materials, and systems for aircraft production. These suppliers support both Boeing and other aerospace companies.

- Aerospace Maintenance, Repair, And Overhaul (MRO) Providers: Seattle houses MRO facilities that specialize in maintaining and repairing aircraft, ensuring they meet safety and performance standards.

- Aerospace Research And Development (R&D) Centers: Seattle is a hub for aerospace R&D activities, with institutions and companies working on cutting-edge technologies, materials, and designs for future aerospace systems.

- Space Exploration Companies: Some companies in Seattle focus on space exploration and satellite technology, contributing to the growing space industry.

- Aviation Service Providers: Seattle has aviation service companies offering services such as pilot training, air traffic control, and aviation consulting.

- Aerospace Finishing Companies: These companies specialize in surface treatment and finishing of aerospace components to enhance their durability, performance, and safety.

- Drone And Unmanned Aerial Vehicle (UAV) Manufacturers: Seattle has seen growth in companies developing drones and UAVs for various applications, including surveillance, research, and commercial use.

- Aerospace Software And Technology Developers: Businesses in Seattle work on software solutions, data analytics, and technology innovations that improve aerospace operations and safety.

- Aerospace Startups: The city fosters a dynamic startup ecosystem, with emerging companies focusing on disruptive technologies and solutions in the aerospace sector.

Alternatives To Aerospace Finishing Companies

Alternatives to aerospace finishing companies in Seattle include:

In-House Finishing

In-house finishing refers to the practice of aerospace companies developing their own internal capabilities for surface finishing. This approach allows companies to have direct control over the finishing process, from preparation to application, ensuring it aligns with their specific needs and quality standards.

Outsourcing

Outsourcing in aerospace finishing involves contracting specialized finishing services from external providers. Aerospace companies may choose this option to benefit from the expertise and resources of established finishing companies, allowing them to focus on their core competencies while ensuring high-quality finishing.

Research And Development

Research and development in aerospace finishing involves investing in the exploration and creation of novel finishing solutions. Aerospace companies may engage in R&D to develop proprietary finishing techniques or materials tailored to their unique requirements, fostering innovation and gaining a competitive edge in the industry.

Final Thoughts

Aerospace finishing is an essential component of the aviation, defense, and space industries, contributing to enhanced durability, performance, and compliance. At Valence Surface Technologies, we are proud to be the world’s largest independent aerospace product finishing company. With our commitment to excellence and cutting-edge technology, we ensure that your aerospace components receive the highest quality finishing.

Ready to soar with Seattle’s best? Choose Valence Surface Tech for aerospace excellence! Get in touch for inquiries and request a quote today!

Read also:

- Los Angeles Aerospace Companies

- Blue Origin: History, Achievements, And Future

- SpaceX: History, Achievements, And Future

Frequently Asked Questions

Are there any downsides to aerospace finishing?

Potential drawbacks may include costs, complexity, lead times, and environmental considerations.

How can I find aerospace finishing companies?

You can search online, consult industry directories, or seek recommendations from peers and industry associations.

Can I perform aerospace finishing in-house in Seattle?

Yes, some companies choose to develop in-house finishing capabilities to have direct control over the process.

What services does Valence Surface Technologies offer in Seattle?

Valence offers a completely integrated solution serving the aviation, defense, and space industries, providing comprehensive aerospace finishing services.

What specific aerospace components are typically finished in Seattle?

Aerospace finishing in Seattle covers a wide range of components, including aircraft structures, engine parts, avionics, satellite components, and more.

How can aerospace finishing contribute to sustainability in Seattle?

Aerospace finishing can include eco-friendly coatings and processes that minimize environmental impact, supporting sustainability efforts.

Can aerospace finishing companies in Seattle handle large-scale projects?

Yes, many Seattle-based aerospace finishing companies are equipped to handle projects of various sizes, from small components to large structures.

What is the role of automation in aerospace finishing?

Automation is increasingly used in aerospace finishing to improve efficiency, precision, and consistency in processes such as coating application and quality control.

How do aerospace finishing companies stay up-to-date with industry advancements in Seattle?

Companies invest in ongoing training, research, and collaboration with industry experts to stay current with aerospace finishing innovations.

Can aerospace finishing be applied to both metallic and non-metallic materials in Seattle?

Yes, aerospace finishing can be applied to a variety of materials, including metals, composites, and polymers, to meet specific needs.

Sources:

- Nadcap Consulting. (n.d.). American Quality Management. https://aqmauditing.com/nadcap-consulting/

- Hammar, M. (n.d.). What is AS9100? Easy-to-understand explanation. Advisera.com. https://advisera.com/9100academy/what-is-as9100/#:~:text=The%20AS9100%20standard%20is%20a

- Beers, B. (2022, April 5). Who are the major airplane manufacturing companies? Investopedia. https://www.investopedia.com/ask/answers/050415/what-companies-are-major-players-airline-supply-business.asp