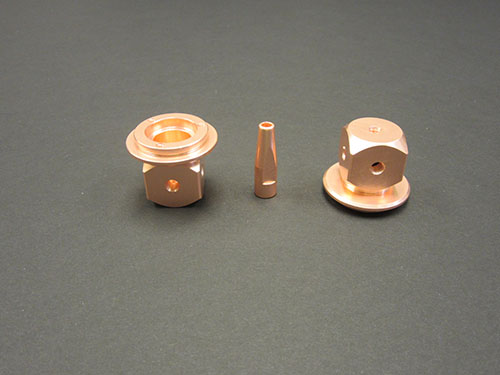

Copper Plating

Copper electroplating at Valence is applied as an undercoat or strike between the substrate and final deposit. We offer a tarnish inhibitor (anti-tarnish) application for those applications that require copper as a final finish.

Our plating methods include Barrel plating, Rack plating, and Brush plating. Barrel and Rack plating are immersion copper plating methods; brush plating is applied outside the tank

Valence Surface Technologies can apply copper plate on aluminum, stainless steel alloys, inconel, monel, copper alloys, steel alloys, and many other substrates.

Copper plating thickness measuring is performed using the X-Ray Fluorescence method in accordance with ASTM B 568. Instruments used to determine copper plating thickness are Fischercope X-Ray units, accomplishing a margin of error less than 1% using certified thickness foil standards.

Custom masking is available for plating selective areas and applying multiple processes to one part.

Request a quote on copper plating for your application, or contact us to learn more.

Copper Plating Process