Manganese Phosphate

Manganese phosphate is an advanced surface coating often used in industries seeking to improve the durability and longevity of components. It’s a conversation that is as much about chemistry as it is about practical benefits for numerous applications, and at Valence we understand just how transformative this process can be. Let’s explore the intricacies and advantages of manganese phosphate, and how Valence harnesses its properties to deliver unparalleled service.

Elevate the performance and longevity of your critical components with Valence Surface Tech’s superior manganese phosphate coatings. Our precision-engineered solutions maximize corrosion resistance, wear reduction, and adhesion, laying the foundation for your industry success. Connect with Valence today to discuss how our expertise in advanced surface coatings can transform your operations and give you the competitive edge you need.

What Is Manganese Phosphate?

Manganese phosphate is a type of conversion coating that provides outstanding protection against corrosion and reduces friction in moving parts. It forms a dark gray to black finish that is non-reflective and absorbs oil, which enhances the lubricating properties of the base metal.

The History Of Manganese Phosphate in Surface Treatment

The roots of manganese phosphating trace back over a century, with developments in surface treatments for arms and automotive manufacturing prompting its adoption. As with many technological stories, the history of manganese phosphate is marked by continual improvements and tailored solutions, developing from a niche-specific procedure to a broad application service.

The Manganese Phosphate Coating Process Explained

Preparation And Pre-Treatment

The path to an effective manganese phosphate coating begins with a rigorous preparation process. Here, Valence meticulously cleans the metal parts, getting rid of oils, previous coatings, and rust—a crucial step that ensures a strong bond between the metal surface and the chemical coating.

Bath Composition And Control

The bath’s precise composition is a critical factor in the coating process, where manganese and phosphate compounds are carefully blended with specific conditioners and accelerators. Valence’s expertise lies in fine-tuning this mixture and maintaining the exact conditions needed to produce a superior, consistent finish.

Coating Application And Formation

This stage sees the prepared components submerged into the phosphate bath, triggering a precise chemical reaction overseen by Valence’s specialists. The result is a uniform conversion of the surface to manganese phosphate, providing the exemplary protection and finish that Valence’s customers have come to trust.

Post-Coating Treatment

After the main coating process, additional treatments, such as oiling or wax sealing, are applied by Valence to further protect against corrosion and to imbue the surface with improved lubricative properties, ensuring the parts meet the functional and aesthetic demands of various industrial applications.

Regulations And Compliance In Manganese Phosphate Coating Operations

Navigating the web of industry standards, environmental regulations, and compliance certifications can be complex. Here’s how these aspects influence manganese phosphate coating operations.

Industry Standards

Adherence to specific industry standards is non-negotiable in the manganese phosphate coating process. These standards stipulate precise specifications to which Valence meticulously aligns, ensuring each coating meets or exceeds the strict criteria set out for safety and performance.

Environmental Regulations

Valence echoes the global call for sustainability by rigorously following environmental regulations. They strive to minimize ecological impact, reflecting their dedication to environmental stewardship in every aspect of the manganese phosphate coating procedure.

Compliance Certifications

Certifications are a badge of honor for Valence, demonstrating their manganese phosphate coatings meet and surpass recognized quality benchmarks. Constantly updating their practices to stay in line with these certifications exhibits their unwavering commitment to top-tier service.

Handling And Safety Protocols

At Valence, safety protocols are paramount, ensuring the welfare of both their workforce and the environment. They implement stringent handling procedures and safety measures throughout the manganese phosphate coating process, upholding their reputation as a conscientious and responsible service provider.

Industrial Applications Of Manganese Phosphate Coatings

Offering superb protection, manganese phosphate coats are crucial for several applications. Let’s delve into the range of industries reliant on this outstanding finishing process.

Aerospace And Defense

In the demanding realms of aerospace and defense, manganese phosphate coatings deliver essential durability and resistance to ensure component longevity and reliability. Valence accurately tailors these finishes to endure the extreme conditions faced by equipment and vehicles in these sectors.

Automotive Industry

The automotive sector relies on manganese phosphate coatings to reduce wear on gears, pistons, and bearings, directly enhancing the performance and extending the operational life of vehicles. Valence’s coatings serve to protect these components against the harsh conditions of the road and under-the-hood environments.

Oil And Gas Exploration

For the oil and gas industry, where machinery faces some of the harshest conditions, the protective capabilities of manganese phosphate coatings are indispensable. Applying Valence’s expertly crafted coatings can significantly increase the corrosion resistance of exploration and drilling equipment, ensuring more robust performance and safety.

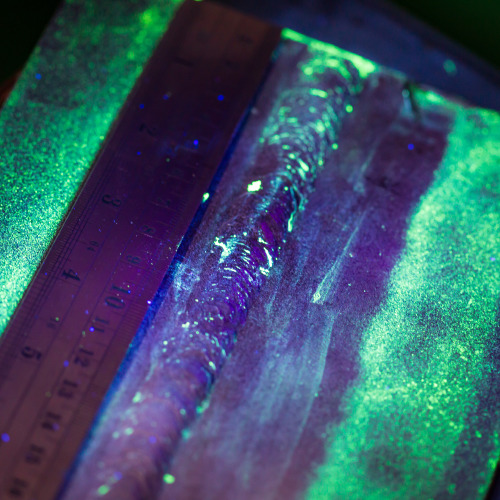

Firearm Manufacturing

In firearm manufacturing, the anti-corrosive and abrasion-resistant properties of manganese phosphate coatings are key to the longevity and reliability of the products. Valence applies its specialty finishes to firearms, enhancing performance and ensuring that they meet the exacting standards expected by military, law enforcement, and recreational users.

Quality Control In Manganese Phosphate Coating

Quality control is pivotal in ensuring the uniformity and resilience of the manganese phosphate finish. A series of checks and balances throughout the coating process guarantees that the highest standards are consistently upheld, a protocol that Valence integrates into every phase of its finishing services.

Valence Surface Technologies Precision In Manganese Phosphate Coating Services

With a history of excellence in surface finishing, Valence stands out as your quintessential partner for manganese phosphate coating services.

State-Of-The-Art Facilities

Valence’s investment in the latest facilities ensures the provision of top-tier manganese phosphate coatings, essential for clients demanding the utmost in surface treatment quality. Their commitment to technological advancements translates into a reliable, premier finish for every component handled.

Customized Solutions

Recognizing the diversity in component designs and functions, Valence extends customized manganese phosphate solutions, meticulously engineered to enhance the specific qualities of each unique piece. This tailored approach not only meets but often exceeds the performance expectations of their clients’ mission-critical applications.

Unmatched Expertise

The expertise that Valence brings to the table is underpinned by a vast array of over 4,500 unique approvals, showcasing their ability to consistently deliver manganese phosphate coatings of exceptional quality. Every team member at Valence is a specialist, contributing their skills to set a benchmark in finishing excellence.

Scalable Operations

Valence’s operations are designed to be as dynamic as the industries they serve, offering scalable solutions that efficiently manage both high-volume production runs and smaller, specialized batches. This adaptability ensures that every client’s demand is met with the same attention to detail and quality, regardless of project scale.

The Environmental Impact Of Manganese Phosphating

An intentional focus on minimizing the environmental impact is critical in today’s industry landscape. Here’s how sustainability comes into play with manganese phosphate coating.

Waste Management

Valence has implemented rigorous waste management protocols to ensure the responsible disposal and recycling of byproducts resulting from the manganese phosphate coating process. Their proactive strategies not only comply with regulatory standards but also minimize the ecological footprint of their operations.

Resource Conservation

Conscious of their environmental responsibilities, Valence actively conserves water and energy, optimizing their manganese phosphate coating operations to achieve more with less. Their initiatives in resource conservation reflect a dedication to preserving our planet’s natural reserves and showcase their role as environmental stewards.

Compliance And Innovations

By embracing compliance as a cornerstone of its values, Valence consistently meets and often exceeds environmental regulations. Their embrace of innovation drives the adoption of cleaner, more sustainable technologies, confirming Valence’s stature as an environmentally conscious leader in the surface treatment industry.

Benefit Analysis Of Manganese Phosphate Coatings

The benefits of manganese phosphate coatings are diverse and substantial, impacting various aspects of the manufacturing and operational process.

Corrosion Resistance

Valence’s manganese phosphate coatings are particularly esteemed for their significant enhancement of corrosion resistance. This critical attribute serves to notably extend the service life of parts and components, a testament to Valence’s dedication to longevity and durability.

Wear Reduction

The company’s expertise in applying manganese phosphate coatings is instrumental in diminishing surface-on-surface wear. This is especially crucial for the functionality of moving parts, where Valence’s precision coating reduces friction and prevents premature wear and tear.

Enhanced Adhesion

Valence ensures that surfaces treated with their manganese phosphate coating exhibit superior adhesion qualities, providing an optimal foundation for paints and other finishes. The result is a synergistic enhancement of protective layers that clients depend on for increased performance and protection.

Lubricity And Aesthetics

Valence further enhances the value of their manganese phosphate coatings by ensuring they contribute to the lubrication of the parts, reducing maintenance needs and improving operation smoothness. Moreover, the coatings contribute to the aesthetics, presenting a professional and visually appealing finish that suits high-standard industry requirements.

Adopting manganese phosphate coatings can be transformative for your business. Valence is proud to be a partner in progress, ensuring that your components are safeguarded with best-in-class service and expertise. Reach out to explore how we can elevate your surface finishing needs.

Final Thoughts

Valence is an embodiment of excellence in manganese phosphate surface finishing, providing aerospace, military, and defense industries with top-tier services that include unmatched expertise, a commitment to quality, and innovative, scalable solutions. They are not just service providers—they are long-term partners in the success of each client’s mission.

Frequently Asked Questions About Manganese Phosphate

What makes manganese phosphate a preferred choice over other surface coatings for industrial applications?

Manganese phosphate provides excellent corrosion resistance and reduces friction in moving parts, enhancing durability.

How long has manganese phosphate been used in surface treatments?

Manganese phosphate’s use dates back over a century, particularly in arms and automotive manufacturing.

Can manganese phosphate coatings be customized for specific component designs and functions?

Yes, Valence Surface Tech offers customized solutions tailored to unique component requirements.

What distinguishes Valence’s facilities in providing manganese phosphate coatings?

They invest in state-of-the-art facilities to ensure top-tier coatings essential for clients requiring high-quality surface treatments.

Does Valence employ any waste management strategies in the manganese phosphate coating process?

Yes, they have rigorous protocols for responsible disposal and recycling of byproducts, complying with regulations.

Can Valence’s manganese phosphate coatings reduce maintenance needs in industrial applications?

Yes, the coatings contribute to lubrication, reducing maintenance requirements.

Do manganese phosphate coatings impact the adhesion of paints and other finishes on surfaces?

Yes, they provide a superior foundation for subsequent protective layers, enhancing adhesion.

How does Valence ensure safety during the manganese phosphate coating process?

They implement stringent handling procedures and safety measures, prioritizing the well-being of their workforce and environment.

What sets Valence’s expertise apart in the manganese phosphate coating field?

They hold over 4,500 unique approvals, showcasing consistent delivery of exceptional coatings.

Can manganese phosphate coatings be applied to a wide range of materials?

Yes, they can be applied to various metals to enhance their durability and performance.

Sources:

- American Galvanizers Association. (2023). Corrosion basics. https://galvanizeit.org/corrosion

- ASM International. (2018). Corrosion of materials. http://ftp.demec.ufpr.br/disciplinas/TM315/Asm%20Metals%20Handbook%20Volume%2013%20-%20Corrosion%20Fundamentals,%20Testing,%20And%20Protection.pdf

- National Association of Corrosion Engineers. (2022). Corrosion control engineering handbook. https://store.ampp.org/nace-corrosion-engineer-s-reference-guide-4th-edition-e-book-

- ASM International. (2018). Friction, lubrication, and wear technology. https://dl.asminternational.org/handbooks/edited-volume/50/Friction-Lubrication-and-Wear-Technology

- The Finishing Society. (2023). History of metal finishing. https://www.linkedin.com/pulse/brief-history-growth-future-surface-finishing-sunil-goel

- American Electroplaters’ and Surface Finishers’ Society. (2023). History of AESF. https://uia.org/s/or/en/1100041684

- Valence Surface Tech. (2023). Manganese phosphate coatings. https://www.valencesurfacetech.com/

- ASTM International. (2023). ASTM B633 – standard specification for electrodeposited coatings of zinc on iron and steel. https://www.gattoplaters.com/astm-b633.html

Plating Services

Cadmium Plating

Cadmium plating is a tough and versatile coating. The soft, attractive coating provides a favorable bonding surface for adhesions. It is also the preferred plating for salt-water environments due to its resistance to mold and bacteria.

Chrome Plating

Chromium plating is effective at providing excellent hardness and lubricity, reducing friction, minimizing wear, and preventing galling. In environments with corrosion or abrasion, chrome plating can withstand negative consequences on wear and tear.

Gold Plating

Gold plating advantages include good corrosion resistance, good solderability, and, when alloyed with cobalt, it has very good wear resistance. Gold is commonly used in electrical switch contacts, connector pins and barrels, and other applications where intermittent electrical contact occurs. It is also used as a radiation shield, in infrared reflectors and satellite electronic housings. Valence also offers immersion gold plating.

Manganese Phosphate

Manganese phosphate coating is a conversion coating, the formulation of which contains a manganese salt, phosphoric acid and an accelerator. This process is done under high temperature, and produces a surface that has good corrosion and wear resistance. Manganese phosphate coatings can retain oil and other lubricants.

Nickel Sulfamate

Nickel sulfamate is a plating process that provides a highly ductile plating surface with low internal stress. The versatility of the coating resists high temperatures, maintains high tensile strength, and provides ductility and elongation.

Ti-Cad Plating

Ti-Cad or titanium cadmium plating is a titanium cadmium combination plating that provides corrosion resistance on high strength steel applications. It significantly reduces the negative consequences of hydrogen embrittlement.

Tin Plating

Tin plating is used extensively to protect both ferrous and nonferrous surfaces. Tin is also widely used in the electronics industry because of its ability to protect the base metal from oxidation and corrosion. Depending on the base material, tin is used as a metal plating to maintain or impart solderability. Valence also offers tin lead plating.

Valence performs all of these services to the highest degree of care, with approvals for most prime, aerospace, and military specifications. Our products and services significantly enhance safety, long-term use, and consistency in the aerospace industry. View our specs here.

Plating Tank Sizes

| Valence Wichita | L | Valence Garden Grove | L |

|---|---|---|---|

| Cadmium Types I, II, III | 4′ | Copper Plate | 2′ |

| Electroless Ni-Mid | 4′ | Electroless Ni- Hi Phos | 6′ |

| Electroless Ni-Hi Phos | 2.5′ | Electroless Ni- Low phos | 3′ |

| Hard Chrome | 14′ | Electroless Ni- Mid phos | 7.5′ |

| Hard Chrome | 7′ | Gold Immersion | 2′ |

| TiCad | 4′ | Gold Plate – Grade A Type lll | 2′ |

| Gold Plate – Grade C, Type II | 3.5′ | ||

| Gold Plate – Grade D, Type I, Type II | 1.5′ | ||

| Gold Strike | 3′ | ||

| Nickel Plate – Bright /Semi Bright | 4.5′ | ||

| Nickel Plate – Semi Bright | 4.5′ | ||

| Nickel Sulfamate | 4.5′ | ||

| Silver Plate – Semi Bright | 3.5′ | ||

| Sliver Plate – Matte | 5′ | ||

| Tin Plate | 4.5′ | ||

| Tin/Lead Plate (60/40) | 3′ | ||

| Tin/Lead Plate (90/10-95/5) | 2.5′ |

Plating News

Chrome Coating: A Necessary Investment for Aerospace Components

Chrome coating is not just a crucial investment, it's a necessity for aerospace components that are exposed to harsh conditions during flight. It offers a range of benefits, including enhanced durability, corrosion resistance, and improved performance. If you want to...

Gold Plating: The Best Way To Protect Aerospace Components From Tarnish

In the aerospace industry, the significance of gold plating cannot be overstated. This process plays a crucial role in safeguarding vital components against the detrimental effects of tarnish and corrosion. Unlike alternative plating techniques, gold plating stands...

Understanding The Different Types Of Gold Plating

Gold plating serves as a renowned metal finishing strategy that incorporates a delicate gold layer onto a metal object's surface. This gold veneer delivers an array of advantages such as augmented corrosion resistance, superior electrical conductivity, enhanced heat...

Choosing The Right Finish: Anodizing Vs. Powder Coating

Choosing the appropriate finish for a project, such as anodizing or powder coating, can present quite a challenge. Both of these finishes have distinct advantages and considerations, making it crucial to fully grasp their unique characteristics to guide your...