Gold is considered malleable, virtually indestructible, highly biodegradable, and almost impervious to the effects of water, air, and oxygen. Due to its unique combination of qualities, it is an essential component in several industrial, aerospace, medicinal, and electrical applications. One of the most thermally and electrically conductive metals is gold, which is also a superb heat conductor.

Parts that need to be flexible and resistant to wear or corrosion benefit from gold plating. The element has a high electrical conductivity and is non-reactive. The best technique to guarantee the value and quality of your product, despite the fact that it is the most expensive electroplating option, is by far this.

In this article, we will explore how gold is used in aerospace, why it is used, and the benefits of gold plating for satellites.

Please contact us if you have questions about your gold plating project, and we’d be happy to help.

How Is Gold Used In Aerospace?

In the aerospace sector, gold is frequently employed in a wide range of applications. Gold plating is one of the most common uses of gold in the aircraft industry. A thin layer of gold is added to a metal or plastic surface during the gold plating process. The use of gold plating improves the material’s look and offers corrosion and wear resistance.

Because of its unique properties, gold plating is very common in the aerospace industry. Considering how well it conducts electricity, gold is frequently utilized in electrical components like wire, circuits, and connectors.

Moreover, it has a high level of corrosion resistance, making it perfect for usage in situations with a lot of moisture and humidity. Gold can be utilized in components that need a non-magnetic environment because it is likewise non-magnetic.

Why Gold Plating For Aerospace?

Gold plating is a popular choice for aerospace applications due to its durability and resistance to corrosion. The metal plating technique is used to give satellites and other spacecraft a sleek and glossy appearance as well as to shield delicate electronic components from the harsh environment of space. Gold plating offers the best defense against the harsh conditions, radiation, and other elements present in space. Moreover, gold plating adds a layer of insulation that can assist shield delicate components from electrical noise.

Gold plating also provides a sleek and polished look to satellites and other spacecraft. Gold plating can help give a spacecraft a more aesthetically pleasing look, making it easier to spot in the night sky. Gold plating can also be used to provide a layer of insulation that can help protect sensitive components from electrical interference. Gold plating is also corrosion-resistant, meaning it can withstand the harsh environment of outer space for longer periods of time.

Overall, gold plating is an ideal choice for aerospace applications due to its durability and resistance to corrosion. Gold plating provides superior protection against extreme temperatures, radiation, and other elements that are present in outer space. Gold plating also provides a layer of insulation that can help protect sensitive components from electrical interference. Gold plating can also provide a sleek and polished look to satellites and other spacecraft and a layer of insulation that can help protect sensitive components from electrical interference.

What Is Electroplating?

Electroplating is a process that uses an electrical current to coat a conductive material, such as metal, with a thin layer of another metal. It is used in many industries, including aerospace, to create a protective layer that is resistant to corrosion and wear. In the aerospace industry, gold plating is often used to improve the performance of satellites and other components.

The process of electroplating involves passing an electric current through a solution that contains a metal salt. The metal salt is usually a compound of the metal that is being plated. As the current passes through the solution, the metal atoms are attracted to the surface of the object being plated. This process is known as electrolysis.

The object to be plated is connected to the negative terminal of the power source and the metal salt solution is connected to the positive terminal. As the current passes through the solution, the metal atoms are attracted to the object and form a thin layer on the surface. This layer is known as plating.

How Electroplating Works

Electroplating is a process that uses an electrical current to deposit a thin layer of metal onto a surface. Usually, a precious metal such as gold, silver, or platinum is the metal that is deposited. It is frequently utilized to make aesthetically pleasing or useful surfaces on products like jewelry, electronics, and even satellites.

The preparation of the surface to be electroplated is the first step in the process. This may require cleaning, polishing, etching, and other treatments to guarantee that the surface is prepared to accept the metal plating. The next step is to fasten the object to the anode, which is the power source’s positive terminal. After that, a metal-ion-containing liquid called an electrolyte solution is used to suspend the object to be plated.

When electricity is applied to the anode and cathode, the metal ions in the electrolyte solution are attracted to the anode. The metal ions then attach themselves to the surface of the item to be plated, forming a thin layer of metal. The thickness of the metal layer can be controlled by adjusting the voltage, current, and duration of the electroplating process.

Once the desired thickness of metal has been deposited, the item can be removed from the electrolyte solution and the electroplating process is complete. The item is now covered with a thin layer of metal that can provide a decorative or functional surface. Gold plating is often used in aerospace applications such as satellites because of its superior corrosion resistance and its ability to reflect infrared radiation. It also provides electrical insulation, reduces electrical resistance, and prevents electrical arcing.

Gold Plating In Satellites

The procedure of gold plating is used to apply a thin layer of gold to satellite surfaces. Due to its special qualities, gold plating has been used in the aerospace sector for decades. Satellite surfaces are shielded by gold plating from damaging radiation, high temperatures, and other factors. Moreover, gold plating acts as insulation and lessens electrical interference in satellites.

Gold plating is done by electroplating, a process in which a thin layer of gold is deposited onto the surface of a satellite. The process begins by attaching a small piece of gold to the surface of the satellite. This gold is then connected to a power source, and an electrical current is passed through it. This current causes the gold to be deposited onto the surface of the satellite. The thickness of the gold layer can be adjusted depending on the desired protection or insulation.

For many reasons, the process is cost-effective for protecting satellites from the elements. Gold is an extremely durable metal, and it is resistant to high temperatures, radiation, and other environmental factors. Gold plating also provides insulation, which helps to reduce electrical interference. This makes it ideal for use in satellites, as it helps to ensure that they are able to communicate effectively with Earth.

How Much Gold Is Used In Satellites?

The amount of gold used in satellites varies depending on the type of satellite and the purpose it serves. Generally, small satellites use less gold than large satellites, and commercial satellites use more gold than government-run satellites. For example, a small CubeSat might use as little as 0.1g of gold, while a larger satellite could use up to 5kg of gold.

In addition, the amount of gold used in a satellite also depends on the type of gold plating used. For example, electroplated gold is usually used for components that require a thin layer of gold for protection, such as antennae, connectors, and electrical components. In this case, the gold layer is usually only a few microns thick, and the amount of gold used is usually less than 1g.

On the other hand, thick-film gold plating is used for components that require a thicker layer of gold, such as parts that need to be highly resistant to corrosion or heat. In this case, the gold layer can be up to 1mm thick, and the amount of gold used can range from 1g to 5kg.

Overall, the amount of gold used in satellites can range from as little as 0.1g to as much as 5kg, depending on the type of satellite, the purpose it serves, and the type of gold plating used.

Benefits Of Gold Plating

Gold plating is a popular choice for aerospace applications due to its many benefits. Gold plating provides excellent electrical conductivity, corrosion resistance, and wear resistance. Gold plating is also an extremely durable finish that can withstand extreme temperatures and harsh environmental conditions.

Superior Electrical Conductivity

Gold plating offers superior electrical conductivity compared to other metals, making it an ideal choice for electrical components in satellites. The gold plating acts as a barrier, protecting the underlying metal from oxidation and corrosion. This helps to ensure that the components remain functional and reliable, even in extreme environments.

Excellent Wear Resistance

Gold plating also provides excellent wear resistance. The gold plating helps to protect the underlying metal from wear and tear. This ensures that the components remain in good condition and can withstand the rigors of space travel.

Highly Reflective Material Is Produced

Gold plating also produces a highly reflective material, which helps to reduce the amount of solar radiation absorbed by the satellite. This helps keep the satellite cool and reduces the energy needed for cooling.

Durability

Finally, gold plating is an extremely durable finish that can withstand extreme temperatures and harsh environmental conditions. This helps to ensure that the components remain functional and reliable, even in extreme environments.

Properties Of Gold

Gold is a precious metal that has been used for centuries for its many properties and benefits. It is a chemical element with the symbol Au and atomic number 79. Gold is a soft, malleable, ductile metal with a bright yellow color. It is also an excellent conductor of electricity and heat, making it ideal for use in a range of applications.

Gold is one of the most abundant elements on Earth and is found in its elemental form and various compounds. It is found in nature in its native form, or in compounds with other elements such as silver and copper. Gold is also found in the form of alloys, which are mixtures of gold and other metals, such as copper and silver.

Gold is incredibly durable and resistant to corrosion and rust, making it a great choice for aerospace applications. It is also highly reflective, so it can be used to reflect light and heat. Gold is also highly malleable, so it can be shaped into thin sheets or wires and used in electronics. Finally, gold is non-magnetic, which means it won’t interfere with electrical signals.

These properties make gold a great choice for use in aerospace applications, such as satellites and spacecraft. Gold plating is used to protect the metal from corrosion and wear, and its reflective properties make it ideal for heat and light reflection. Gold is also used to make electrical contacts in satellites and spacecraft, as it is an excellent conductor of electricity. Gold also coats parts of spacecraft to protect them from extreme temperatures and radiation.

Other Applications For Gold In Aerospace

Other applications for gold include wires, connectors, and components. As gold is such a good conductor of electricity, it is perfect for usage in situations where electricity needs to be carried. It is a wonderful option for aircraft components because it is also resistant to corrosion and has a low coefficient of friction.

Both commercial and military aerospace applications use gold. Gold is also frequently used in electrical connectors and satellite wire in commercial flights. Switches, relays, and circuit breakers for spacecraft and aviation are also made of gold. In addition, gold is utilized in turbine blades, fuel injectors, and spark plugs for aircraft engines.

Furthermore, in military aerospace applications, gold is used in components for aircraft and missiles, such as antennas, receivers, and transmitters. Gold is also used in radar, navigation, and communication systems components. Gold is also used in components for missiles, such as guidance systems and detonators. Gold is also used in components for military aircraft, such as sensors and actuators.

Get A Gold Plating Quote

Getting a gold plating quote is essential for any aerospace project that requires gold plating. A gold plating quote will give an idea of the project’s cost and the quantity of gold required. Obtaining a quote from a trustworthy gold plating business that focuses on aerospace applications is crucial.

It’s important to give the company thorough project details when requesting a gold plating quote. This pertains to the size of the component, the type of metal being plated, and the preferred finish. The desired result and the gold plating’s thickness must both be specified. Based on the information given, the business ought to be able to offer a quote.

It’s also important to find out the company’s experience working on aerospace projects and the gold plating procedure. Ask them specifically if they have any experience with gold plating for satellites and other aerospace applications. Finding out the company’s turnaround time and the cost of the gold plating procedure is also crucial.

Last but not least, be sure to inquire about the company’s quality control procedure. High levels of accuracy and precision are needed when gold plating for aerospace applications. According to a company’s quality control procedure, the gold plating process should be done accurately and to the highest standards.

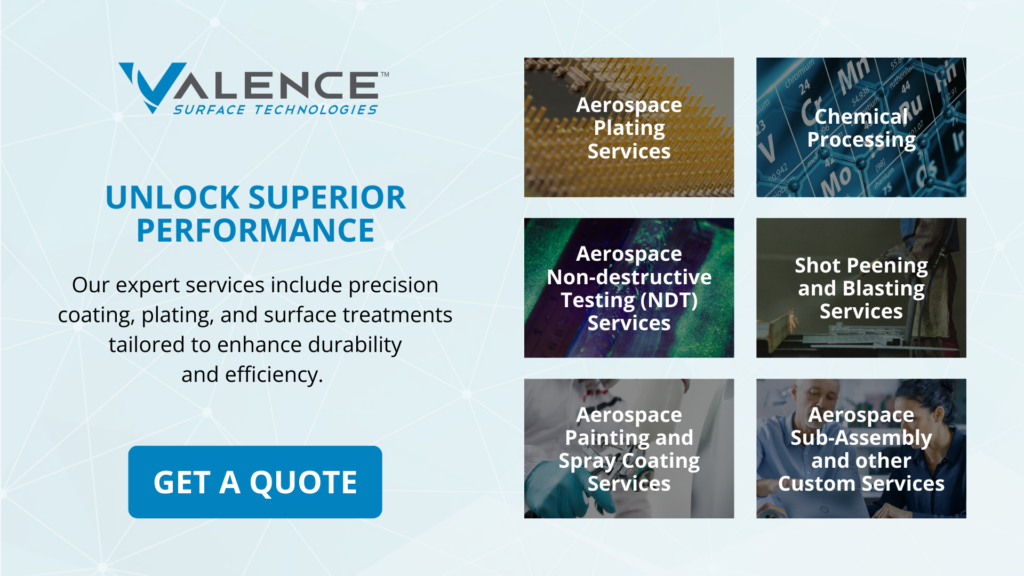

Valence Surface Technologies is a full-service surface finishing company specializing in the commercial aerospace, defense, space and satellite industries. With ten strategically located sites across the United States, Valence provides a start to finish solution from NDT and chemical processing, to paint and sub-assembly.

Please contact us or get a quote for your gold plating project today.

Final Thoughts

Gold plating has been used in aerospace for decades and is essential to satellite construction. Gold plating is used to protect the satellite from the harsh environment of space and reduce the amount of heat generated by the satellite. Gold plating also helps to reduce the amount of electrical interference, which is important for the satellite’s communication and navigation systems.

The use of gold plating in the aerospace industry is highly beneficial for a variety of reasons. Gold plating provides a protective barrier against the harsh environment of space and is also able to regulate temperatures.

If you have any questions or need help with nickel plating services, our experienced team is here to help. Give us a call, and we’ll get back to you as soon as possible. With Valence Surface Technologies, you can rest easy knowing your parts are in the best hands

FAQs

What is the gold material on satellites?

Gold plating is the most common gold material used on satellites. Gold plating is a process where a thin layer of gold is electroplated onto a substrate, usually made of metal or plastic. Gold plating reduces electrical resistance, resists corrosion, and protects the surface from wear and tear.

How much gold is used in a satellite?

The amount of gold used in a satellite varies depending on the size of the satellite and its purpose. Generally, a small satellite will require a few grams of gold, while a larger satellite may require up to a few kilograms of gold.

What precious metals are used in satellites?

Gold is the most common precious metal used in satellites, but other metals such as silver and platinum, are also used for various applications. Silver is used for electrical contacts, while platinum is used for its corrosion resistance and durability.

Why does Nasa use gold?

Gold is used in satellites because it is a reliable and durable material that can withstand extreme temperatures, resist corrosion, and provide electrical insulation. Gold is also a good conductor of heat and electricity, making it an ideal material for space applications.

Why are satellites gold plated?

Gold plating reduces electrical resistance, resists corrosion, and protects the surface from wear and tear. Gold plating also provides a reflective surface, which can help to reduce the amount of heat absorbed by the satellite. Gold plating also gives the satellite a polished, professional look.