Key Takeaways:

- Importance of MIL-STD-130 Compliance: Adhering to MIL-STD-130 guidelines is crucial for efficiently managing military property through proper tracking, management, and accountability procedures.

- Significance of Unique Identification (UID) in Military Asset Management: UID is essential in military asset management as it facilitates accurate tracking, enhances inventory visibility, promotes interoperability, and ensures data integrity throughout the supply chain.

- Best Practices for MIL-STD-130 Marking Methods: Employing proper marking methods such as Data Matrix barcodes, chemical etching, and laser marking is essential for MIL-STD-130 compliance and ensuring durable and readable item markings.

In the aerospace industry, precision, reliability, and safety are paramount. As such, stringent standards are essential to govern every aspect of production, including surface finishing. MIL-STD-130 is a cornerstone in this domain, providing comprehensive guidelines to ensure the quality and compliance of surface finishing processes within aerospace applications.

Established by the United States Department of Defense, MIL-STD-130 delineates the requirements for identifying items of military property. It encompasses a broad spectrum of criteria, ranging from marking methods to data formatting, all aimed at facilitating traceability, asset management, and interoperability across the aerospace supply chain.

In this article, we discuss the significance of MIL-STD-130 in the aerospace sector and how it ensures compliance, traceability, and quality control in surface finishing processes. Explore this standard’s vital role in upholding industry standards and facilitating seamless operations in the aerospace supply chain.

Unleash the full potential of your aerospace surface finishing needs with Valence Surface Technologies. Experience the difference of working with the industry leader in quality, reliability, and innovation. Trust Valence to elevate your projects to new heights.

Understanding MIL-STD-130

When it comes to military property identification, adhering to the guidelines outlined in MIL-STD-130 is crucial for efficient tracking, management, and accountability. Below, we discuss key principles and requirements set forth by MIL-STD-130:

Unique Identification Markings

MIL-STD-130 mandates using unique identification markings, often in the form of Data Matrix symbols, to provide each item with a distinct identifier. These markings must be durable and legible throughout the asset’s life cycle, enabling easy scanning and retrieval of essential information.

Item Unique Identification (IUID)

IUID is a key component of MIL-STD-130, requiring items to be uniquely identified to facilitate traceability and interoperability across the Department of Defense (DoD) supply chain. By assigning a unique IUID to each item, organizations can enhance asset visibility, streamline logistics processes, and ensure accurate inventory control.

Verification and Validation

Compliance with MIL-STD-130 involves rigorous verification and validation processes to confirm the accuracy and integrity of identification markings. This includes verifying that the markings meet specified requirements, such as size, location, and data content, and conducting periodic validation to prevent errors and discrepancies.

Data Management

Effective data management is essential for MIL-STD-130 compliance, encompassing creating, maintaining, and sharing item data under established standards and protocols. By centralizing and standardizing data within a robust management system, organizations can improve data accuracy, accessibility, and security.

Compliance and Certification

To ensure conformance with MIL-STD-130, organizations must undergo certification processes to demonstrate compliance with the standard’s requirements. Certification validates adherence to best practices in military property identification, underscoring a commitment to quality, reliability, and compliance with regulatory standards.

By understanding and implementing the guidelines outlined in MIL-STD-130, organizations can enhance operational efficiency, strengthen asset management practices, and uphold the stringent requirements of military property identification within the aerospace, defense, and space industries.

The Significance of Unique Identification (UID) in Military Asset Management

As specified by MIL-STD-130, UID is a crucial component of item marking and tracking systems used by the Department of Defense (DoD) and its contractors.

- Tracking and Traceability: UID facilitates accurate monitoring of assets, including components, parts, tools, and systems. This enables military organizations to maintain detailed records of location, maintenance history, and other essential information, enhancing inventory management and operational efficiency.

- Enhanced Inventory Visibility and Control: UID implementation promotes better visibility and control over inventory, reducing the risk of theft, loss, or misplacement of critical assets. Standardized identification systems enable rapid asset location and verification, supporting timely decision-making and mission readiness.

- Interoperability and Data Integrity: UID compliance facilitates interoperability between military branches and allied forces by standardizing identification protocols. This ensures seamless communication and coordination, particularly in joint operations. Furthermore, UID enhances data accuracy and integrity, enabling precise record-keeping of asset utilization, maintenance schedules, and configuration changes across the military supply chain.

Marking Methods for MIL-STD-130 Compliance: Best Practices and Techniques

When achieving MIL-STD-130 compliance for aerospace products, employing the right marking methods is crucial. The Department of Defense requires specific identification markings on items to ensure traceability, accountability, and quality control throughout the product lifecycle. Here are some best practices and techniques to consider for marking your products by MIL-STD-130:

Data Matrix Barcodes

Utilizing Data Matrix barcodes is a highly effective method for marking aerospace parts. These two-dimensional codes can contain significant information in a compact space, including part numbers, serial numbers, and other important data. Data Matrix barcodes are durable, machine-readable, and can withstand harsh environmental conditions, making them ideal for aerospace applications.

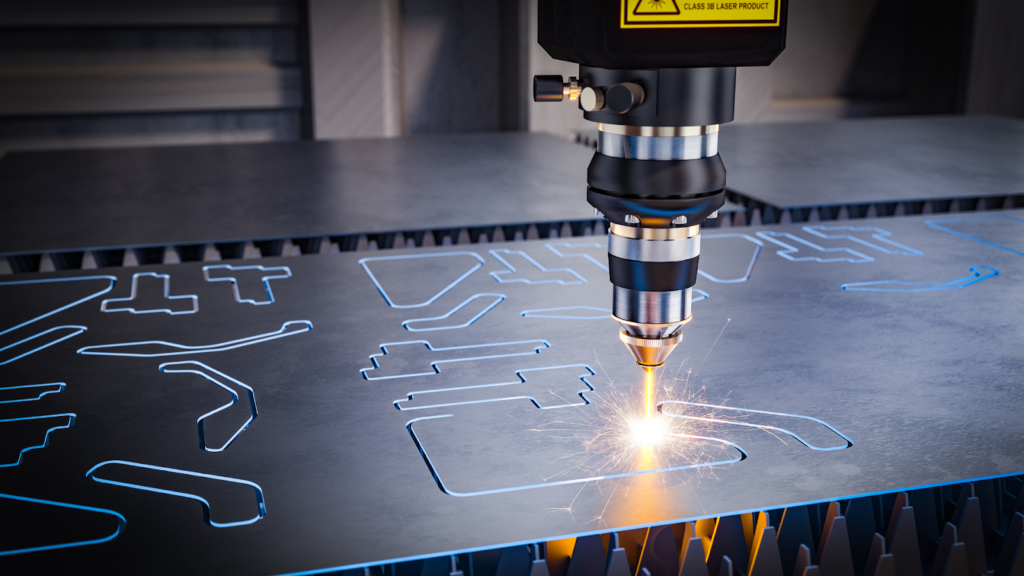

Laser Marking

Laser marking offers fast and accurate marking capabilities for aerospace components. This non-contact method uses a focused laser beam to engrave or etch information onto the part’s surface. Laser marking provides high contrast and resolution, making it suitable for marking a wide range of materials while meeting MIL-STD-130 requirements.

Chemical Etching

Chemical etching is a precise and permanent marking method that is commonly used for MIL-STD-130 compliance. This process involves using chemicals to remove material from the part’s surface, creating a clear and durable mark. Chemical etching allows for high-resolution markings that meet stringent military standards for readability and longevity.

Essential Information Content for MIL-STD-130: What Every Contractor Needs to Know

Adhering to the stringent regulations of MIL-STD-130 is crucial for contractors to align with the directives of the U.S. Department of Defense. Here’s a concise rundown:

Unique Item Identification (UID)

Each UID must be marked permanently in compliance with MIL-STD-130. The UID consists of two elements: the Data Matrix symbol and the human-readable information. The Data Matrix symbol contains machine-readable data that can be scanned and decoded, providing crucial information about the item.

Data Matrix Symbology (DMS)

The Data Matrix symbology is a two-dimensional matrix barcode consisting of black and white cells arranged in either a square or rectangular pattern. Contractors must ensure that the Data Matrix symbol adheres to specific size, content, and quality criteria outlined in MIL-STD-130. The DMS contains essential data elements such as the part number, serial number, and lot number necessary for tracking and identification purposes.

Ensuring accurate and compliant marking of items according to MIL-STD-130 is essential for contractors working with the Department of Defense. Failure to meet the requirements of MIL-STD-130 can result in costly delays, rejected deliveries, and potential loss of contracts. By understanding and implementing the essential information content outlined in MIL-STD-130, contractors can streamline processes, enhance traceability, and maintain compliance with government standards.

Verifying Compliance: Ensuring MIL-STD-130 Markings Meet DoD Standards

Verification processes play a significant role in guaranteeing that these markings meet the necessary standards. Here is what to note:

- Verification Equipment for Compliance: High-quality verification tools, including barcode scanners, optical readers, and verification software, ensure that MIL-STD-130 markings meet the necessary standards. These tools assess the markings’ readability, accuracy, and quality, helping identify discrepancies or errors.

- Inspection of Marking Elements: The verification process involves inspecting various elements of the markings, such as data matrix codes and human-readable text. Disc discrepancies can be identified and promptly rectified through a thorough inspection to ensure compliance with MIL-STD-130 standards.

- Regular Audits and Inspections: Regular audits and inspections are critical for maintaining ongoing compliance with MIL-STD-130 standards. Companies can proactively address issues and maintain consistency in their markings by conducting routine checks and assessments.

- Collaboration with Suppliers: Collaboration with trusted partners and suppliers, such as experienced surface finishing companies like Valence Surface Technologies, is key to achieving compliance with MIL-STD-130 requirements. Working together provides access to expertise and resources to ensure that markings align with DoD standards.

How Contractors and Suppliers Can Adhere to MIL-STD-130

Adhering to MIL-STD-130 requires contractors and suppliers to establish robust marking processes that meet the standards’ specifications. These processes encompass specific identification methods like machine-readable data matrices, human-readable text, and any additional information dictated by the contract or part requirements.

Maintaining accurate records of these marking processes is crucial for demonstrating compliance during audits or inspections. A comprehensive quality management system that includes marking, verification, and documentation procedures is necessary to ensure consistency and accuracy.

By proactively meeting MIL-STD-130 requirements, contractors and suppliers bolster their reliability, reputation, and competitiveness. Compliance ensures regulatory adherence and signifies a dedication to quality and accountability across the product lifecycle.

Are you curious to explore further? Check out these additional articles.

Frequently Asked Questions on MIL-STD-130

Why is MIL-STD-130 important?

MIL-STD-130 is crucial because it establishes the accepted criteria for the identification marking of U.S. military property. The standard ensures that all items can be identified and tracked throughout their lifecycle, enhancing inventory control, maintenance, and logistical support. Strict adherence to this standard is vital for operational readiness and efficiency for aerospace, defense, and space industries.

What information is required to be included in MIL-STD-130 compliant markings?

MIL-STD-130 compliant markings must include specific information essential for identifying and managing military property. This includes the National Stock Number (NSN), part number, serial number, and the manufacturer’s identification such as CAGE (Commercial and Government Entity) code. The requirements may vary based on the item’s nature and the contractual agreement.

How can compliance with MIL-STD-130 be verified and validated?

Compliance with MIL-STD-130 can be verified and validated through auditing and inspection, which can be conducted internally or by external third parties. Utilizing qualified personnel adept in the specifics of MIL-STD-130 and equipped with appropriate verification tools, such as barcode scanners and UID (Unique Identification) verifiers, is essential for ensuring accurate and reliable validation.

Are there any exemptions or exceptions to MIL-STD-130 requirements?

Yes, there are certain exemptions and exceptions to MIL-STD-130 requirements, mainly based on the item’s specific use, sensitivity, or other unique characteristics. The contracting agency defines these exemptions in detail in the specific contract or agreement. Understanding these exemptions requires close consultation with contracting officers or adherence to specific contractual directives.

What are the consequences of non-compliance with MIL-STD-130?

Non-compliance with MIL-STD-130 can have several consequences, including the rejection of delivered items, delays in contract payments, and potentially diminished reputation with the Department of Defense (DoD) and other contractors. Severe or repeated non-compliance can result in the loss of certification or disqualification from future contracts, affecting business operations and financial standing.

How does MIL-STD-130 compliance impact supply chain management for defense contractors?

MIL-STD-130 compliance significantly impacts supply chain management by imposing strict identification and tracking requirements for all components and finished products. Compliance ensures efficient and accurate logistics, inventory management, and lifecycle support. Defense contractors must integrate compliant marking processes into their supply chain operations to meet these requirements efficiently.

How can small businesses ensure compliance with MIL-STD-130 when working with the Department of Defense?

Small businesses can ensure compliance with MIL-STD-130 by investing in the necessary tools and training to understand and implement the standard’s requirements. Seeking guidance from experienced mentors within the defense contracting community, utilizing resources provided by the DoD and industry associations, and collaborating with partners like Valence Surface Technologies, which have specialized expertise, can offer considerable support.

Does MIL-STD-130 apply only to physical items, or does it cover digital assets and components?

While MIL-STD-130 primarily focuses on marking physical items, certain aspects of the standard can extend to digital assets and components, especially when such items have physical manifestations or are critical to the operation and maintenance of physical military assets. The essence of MIL-STD-130 is the unambiguous identification and traceability of items, whether they are physical or digital.