In the world of surface finishing, precision and clarity are paramount. For companies in the commercial aerospace, defense, space, and satellite industries, achieving excellence in part marking is not just a requirement; it’s a necessity. In this technical article, we delve into the intricacies of part marking, aiming to provide comprehensive insights to companies seeking top-tier surface finishing solutions.

What Is Part Marking?

Part marking is a critical process in the full service finishing industry, especially for companies in the commercial aerospace, defense, space, and satellite sectors. It involves applying identifiable marks or codes on various components or parts for identification, tracking, and quality control purposes.

Unlock Excellence With Valence Surface TechnologiesAt Valence Surface Technologies, we are the unparalleled leaders in aerospace surface finishing. As the world’s largest independent aerospace product finishing company, we take pride in offering a truly integrated solution that caters to the aviation, defense, and space industries. Why Choose Valence?

Experience the Valence difference today, where excellence in aerospace surface finishing is not just a goal—it’s our mission. |

Why Is Part Marking Important?

Part marking plays a crucial role in these industries as it ensures traceability, regulatory compliance, and helps prevent counterfeiting or unauthorized use of components. Moreover, it facilitates efficient inventory management, simplifies maintenance procedures, and enables easy identification of faulty or recalled parts.

How Does Part Marking Work?

Part marking can be accomplished through a range of techniques. These methods allow for precise and permanent marking on a variety of surfaces, including metals, plastics, and composites. The choice of marking technique depends on factors like material composition, part size, required level of detail, and industry-specific requirements.

What Are The Benefits Of Part Marking?

Part marking offers several advantages to companies operating in the aerospace, defense, space, and satellite industries. These benefits include:

Enhanced Traceability And Identification

Part marking enables easy identification and traceability throughout a component’s lifecycle, aiding in quality control and supporting regulatory compliance.

Improved Inventory Management

Marked parts can be efficiently tracked, reducing errors and facilitating accurate inventory management.

Authenticity And Anti-Counterfeiting Measures

Marking parts with unique codes or identifiers helps prevent counterfeiting and ensures the authenticity of components used in critical applications.

Maintenance And Repair Efficiencies

Marked parts simplify maintenance and repair procedures by allowing quick identification of specific components or models.

Enhanced Safety And Compliance

Part marking ensures that components meet required safety standards and regulatory guidelines.

What Are The Alternatives To Part Marking?

While part marking is widely used, there are alternative methods available for achieving similar results:

- Barcoding: Instead of physically marking the part, barcodes can be affixed to components, allowing for easy scanning and identification.

- RFID Tagging: Radio Frequency Identification (RFID) tags can be attached to parts for automated tracking and identification purposes.

- Product Documentation: Detailed documentation, labels, or specifications accompanying the part can provide necessary information without physically marking the component.

What Are The Costs Associated With Part Marking?

Part marking may involve some costs, including initial investment costs and ongoing expenses. Here are some cost considerations related to part marking:

- Equipment: Purchasing or leasing the necessary part marking equipment, such as laser engravers, dot peening machines, or inkjet printers.

- Training: Providing training to operators or technicians to ensure proper and efficient use of the part marking equipment.

- Maintenance: Regular maintenance and calibration of the part marking equipment to ensure consistent and accurate results.

- Consumables: Costs associated with the purchase of marking materials, solvents, or inks used in the part marking process.

What Are The Requirements For Part Marking?

Part marking requirements may vary depending on the industry, specific applications, and regulatory guidelines. Here are some common requirements to consider:

- Material Compatibility: Ensure that the part marking technique is suitable for the material used in the component, such as metals, plastics, or composites.

- Durability and Legibility: The marking should withstand environmental conditions, such as temperature, humidity, or exposure to chemicals, to maintain legibility throughout the part’s lifecycle. Legibility is essential for traceability and identification purposes.

- Accuracy and Precision: Part marking should be applied with precision and accuracy to ensure proper identification. This may include considerations for font size, depth, or placement of the mark.

- Regulatory Compliance: Certain industries, such as aerospace, defense, or automotive, have specific regulations or standards regarding part marking.

What Are The Common Methods Of Part Marking?

Part marking can be achieved through various methods, each with its own advantages and considerations. Here are some common techniques employed in part marking:

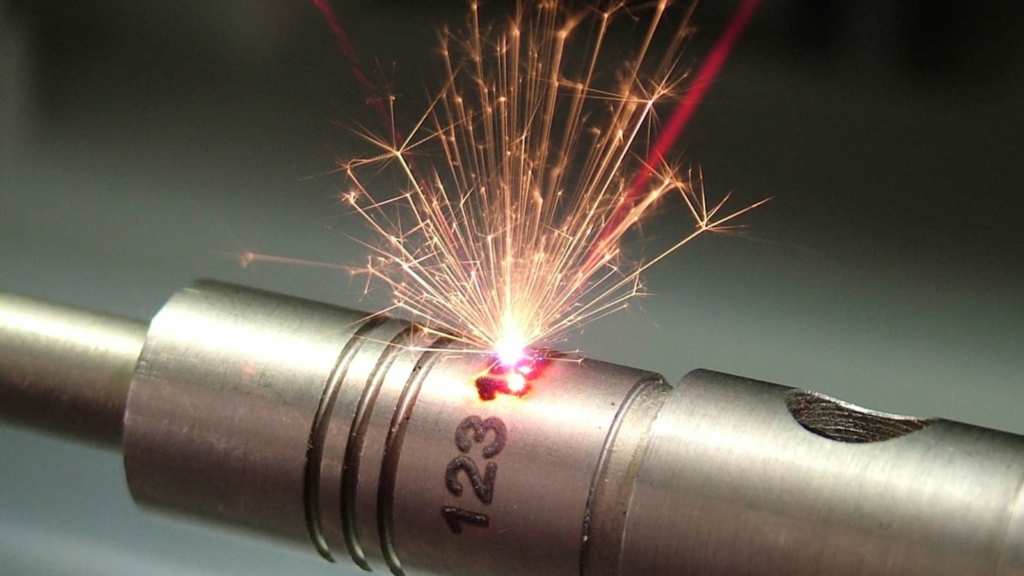

Laser Engraving

- Utilizes a high-energy laser beam to remove material and create a permanent mark.

- Provides high precision, versatility, and durability on a wide range of materials.

- Ideal for 2D or 3D marking, serial numbers, barcodes, and logos.

Dot Peening

- Utilizes a pneumatically driven stylus to create microdots on the part’s surface.

- Offers high-speed marking with deep indentation, suitable for metals and hardened materials.

- Commonly used for serial numbers, logos, and part identification.

Electrochemical Etching

- Involves applying electric current to mark the surface using an electrolyte solution and a stencil.

- Suitable for conductive materials, such as metals, and provides precise, high-contrast markings.

- Often used for part identification, serial numbers, and logos.

Inkjet Printing

- Utilizes specialized inks and printing technology to directly apply markings on various surfaces.

- Offers versatility, high-speed printing, and the ability to produce detailed markings.

- Suitable for barcodes, labels, and product-related information.

What Are The Key Industries That Rely On Part Marking?

Part marking is essential in several industries that require accurate identification, traceability, and compliance. Key industries that rely on part marking include:

- Aerospace: Ensuring part traceability, quality control, and regulatory compliance are crucial in the aerospace industry. Part marking helps identify and track components used in aircraft, satellites, and other aerospace applications.

- Defense: In defense industries, part marking ensures the identification and traceability of critical components used in military equipment, weaponry, and vehicles. It aids in maintenance, repair, and counterfeit prevention.

- Automotive: Part marking is vital for the automotive industry to ensure the authenticity, traceability, and quality of vehicle components. It helps streamline recalls, prevent counterfeiting, and support efficient maintenance procedures.

What Are The Legal And Regulatory Requirements For Part Marking?

Part marking is subject to various legal and regulatory requirements, depending on the industry, location, and specific applications. Here are some key considerations:

- Industry Standards and Specifications: Specific industries may have their own standards or specifications for part marking. Examples include AS9100 for aerospace, MIL-STD-130 for defense, or ISO 13485 for medical devices. Compliance with these standards ensures quality control, traceability, and adherence to industry-specific regulations.

- Unique Identifiers and Serialization: Certain regulations may require the use of unique identifiers, serial numbers, or barcodes on marked components. This enables traceability and assists in identifying faulty or recalled parts during maintenance or repair procedures.

- Environmental and Safety Regulations: Part marking materials and processes must comply with environmental and safety regulations to ensure worker safety and minimize environmental impact. Compliance with regulations such as RoHS (Restriction of Hazardous Substances) or REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) is crucial.

What Is The History Of Part Marking?

Understanding the history of part marking is crucial for appreciating its significance in today’s industries. Part marking has evolved over the years from simple engravings to highly sophisticated laser and digital marking techniques. In the early days, manual engraving was the norm, but as technology advanced, methods became more precise and automated. This historical perspective helps us appreciate the journey of part marking and its role in ensuring product quality, traceability, and compliance with evolving industry standards.

What Does The Current Environment Of Part Marking Look Like?

Today, part marking is a sophisticated and integral aspect of manufacturing in the commercial aerospace, defense, space, and satellite industries. Advanced technologies such as laser marking and digital coding have revolutionized the field, enabling precise, permanent, and efficient markings on various materials. The current environment emphasizes not only the importance of part marking for identification but also its role in ensuring safety, security, and regulatory compliance in these highly specialized industries.

What Does The Future Hold For Part Marking?

As technology continues to advance, the future of part marking holds exciting possibilities. Emerging trends include increased automation, integration with digital systems, and the use of advanced materials for marking. Additionally, as industries evolve, so do regulatory requirements, necessitating ongoing innovation in part marking methods. Staying at the forefront of these developments is essential for a full-service finishing company to remain competitive and continue providing top-of-the-line solutions in the aerospace, defense, space, and satellite sectors.

Frequently Asked Questions About Part Marking

How long does part marking last?

Part marking, when done properly using suitable techniques and materials, can provide permanent markings that last the lifetime of the component. The durability of the marking depends on factors such as the marking method used, material compatibility, and environmental conditions the part may be exposed to.

Can part marking be removed?

Part marking techniques like laser engraving or electrochemical etching create permanent marks that are difficult to remove. However, some techniques like inkjet printing may be less permanent and can be removed with specific solvents or abrasion.

Can part marking be automated?

Yes, part marking can be automated to improve efficiency and accuracy in high-volume production environments. Automated systems can include robotic arms, conveyor systems, or integrated marking machines that can handle part marking processes with minimal human intervention.

Are there any limitations to part marking on different materials?

Different part marking techniques have varying limitations when it comes to specific materials. For example, laser engraving may not be suitable for some plastics or composites due to heat sensitivity, while dot peening may not produce highly detailed markings on certain materials. It is essential to consider material compatibility when selecting the appropriate part marking method.

Can part marking be done on curved or uneven surfaces?

Yes, part marking techniques like laser engraving, dot peening, and inkjet printing can be applied to curved or uneven surfaces with the use of proper fixtures or adjustable marking heads. These techniques can adapt to different surface contours, allowing for accurate and legible markings.

How does part marking assist in counterfeit prevention?

Part marking helps prevent counterfeiting by providing a unique identifier or marking on each component. This allows for easy verification of authenticity and traceability throughout the supply chain. Any unmarked or inconsistently marked components can be identified as potential counterfeits, ensuring only genuine parts are used in critical applications.

Can part marking be used for quality control purposes?

Yes, part marking is commonly used for quality control in various industries. The marked components can be easily tracked, enabling identification of problematic batches or parts that do not meet quality standards. This enhances the overall quality control process and enables quick corrective actions to be taken.

Is part marking required for all components?

The requirement for part marking depends on the specific industry, application, and regulatory guidelines. While many industries, such as aerospace and defense, have stringent part marking requirements, other industries may have more flexible or optional guidelines. It is essential to consult industry-specific standards and regulations to determine the necessity of part marking for specific components.

Can part marking help with inventory management?

Yes, part marking plays a crucial role in efficient inventory management. Marked components can be easily identified, counted, and tracked, which helps reduce errors, streamline inventory processes, and ensure accurate stock management. Marking also facilitates quick and easy part identification during audits or inventory inspections.

Can part marking methods accommodate variable data or serial numbers?

Yes, part marking methods can easily accommodate variable data, such as serial numbers, QR codes, and barcodes, ensuring traceability.