Industrial & Aerospace Metal Plating in Massachusetts

West Springfield, MA 01089

Valence Eastman

Massachusetts is a vital center for aerospace, defense, and advanced manufacturing, driving innovation and excellence in high-performance industries. Valence Surface Technologies proudly supports these industries with expert industrial and aerospace metal plating services. With cutting-edge technology and a commitment to quality, we deliver superior surface finishing solutions tailored to meet the most demanding requirements. For more than 75 years, Valence has realized continual progress through advancement of knowledge and processing technology.

Full-Time Employees

Square Footage

Years Of Experience

Parts Shipped Per Year

Processing Capabilities

Plating & Finishes

Chromate Films

Chromic Acid Anodize

Chromium

Copper

Electroless Nickel Low-Phos. (1%-3%)

Electroless Nickel Mid-Phos. (5%-7%)

Electroless Nickel High-Phos. (10%-12%)

Gold

Hard Anodize

Nickel

Passivation

Phosphoric Acid Anodize

Platinum

Silver

Sulfuric Acid Anodize

Titanium (Caustic) Anodize

Specialty Processes

F-Kote II®

Electroless Nickel-Boron

(PTFE) Teflon®

Electroless Nickel Teflon®

Applied Coatings

Dry Film Lubricants

Anodize/Prime

for Adhesive Bond

Epoxy Coatings

Lacquer Coatings

Resin Coatings

Solid Film Lubricants

Inspection Methods

EIM – Etch Inspection Method

FPI – Fluorescent Penetrant Inspection

LPI – Liquid Penetrant Inspection

Mechanical Finishing

Burnishing (Dry Film Lube)

Scope of Services

On-Site Laboratory

Chemical & Metallurgical Laboratories

Atomic Absorption Unit

Hydrogen Embrittlement Rupture Bar Test

Truck Fleet for Pick Up & Deliveries

Nondestructive Testing

X-Ray Fluorescence

Baking in Vacuum & Inert Atmosphere

R&D Services Available Upon Request

Ultrasonic Cleaning

Salt Spray & Humidity Chambers

Dimensional Restoration of Base Materials

Specialty Plating

Customer Portal

Valence Springfield News

Valence Surface Technologies Acquires H&W Global Industries

EL SEGUNDO, CA, October 25th, 2021─ Valence Surface Technologies LLC (“Valence”) is pleased to announce the acquisition of H&W Global Industries, Inc. (“H&W” or the “Company”), a leading provider of surface treatment for highly engineered products in the...

Valence Surface Technologies Acquires Fountain Plating in Massachusetts

THE WOODLANDS, Texas, February 14, 2020─ Valence Surface Technologies LLC (“Valence”) is pleased to announce the acquisition of Fountain Plating Co., Inc. (“Fountain” or the “Company”), the leader in product finishing services for aircraft engine and critical...

What Is Industrial & Aerospace Metal Plating?

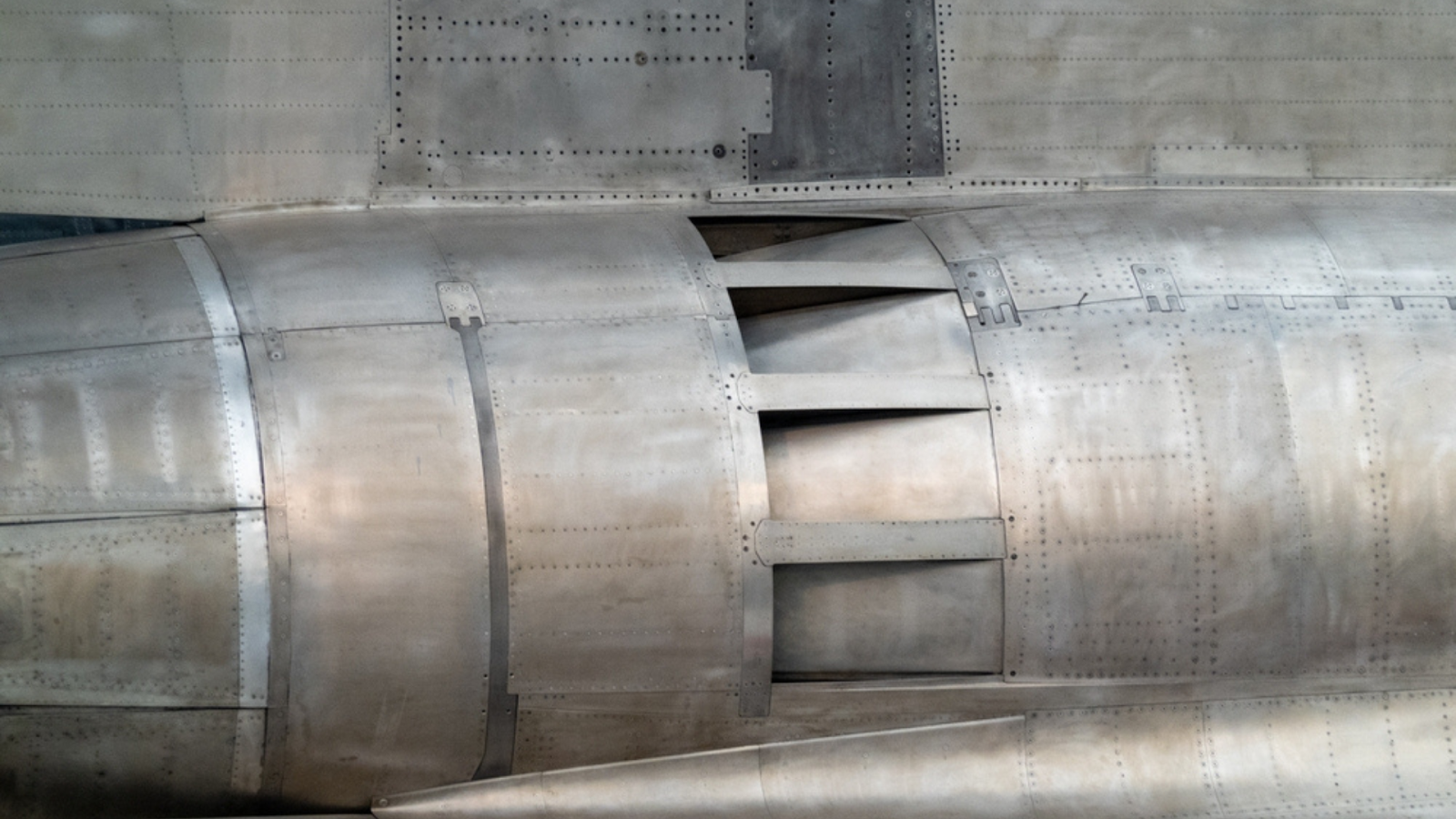

Industrial and aerospace metal plating is a precision electroplating process that applies a protective metal layer to critical components. This treatment improves durability, corrosion resistance, wear resistance, and overall performance, especially in harsh environments like extreme temperatures, high humidity, and chemical exposure.

Metal plating is essential for aerospace and industrial applications, enhancing components like fasteners, connectors, landing gear parts, and hydraulic systems. Valence specializes in cadmium, chrome, nickel, and copper plating, ensuring the highest quality for mission-critical systems.

Why Choose Valence Surface Technologies for Industrial & Aerospace Metal Plating?

Valence Surface Technologies is a trusted leader in metal plating services in Massachusetts, offering a unique combination of technical expertise, state-of-the-art technology, and tailored solutions for aerospace and industrial sectors.

Unparalleled Technical Expertise

Our highly skilled team has years of experience in metal plating, ensuring precision and quality that meet or exceed the strictest industry standards.

Comprehensive Surface Finishing Solutions

We provide a complete range of plating services, including cadmium, chrome, nickel, and copper, to streamline workflows and deliver consistent, high-quality results for all your projects.

Commitment to Quality & Precision

At Valence, quality is our top priority. With advanced technologies and rigorous quality control measures, our Massachusetts facilities deliver metal plating services that ensure optimal performance and compliance with industry standards.

Customized Solutions for Aerospace & Industrial Applications

Every project has unique requirements. Valence works closely with clients to deliver customized plating solutions designed to maximize corrosion resistance, conductivity, and wear protection for critical components.

Experience Aerospace Surface Finishing Excellence With Valence!At Valence Surface Technologies, we take pride in being the world’s largest independent aerospace product finishing company, providing a comprehensive and integrated solution for the aviation, defense, and space industries. Our mission is to be your most trusted partner in aerospace surface finishing. Why Choose Valence?

Discover the Valence advantage today! Experience the benefits of choosing the ONLY completely integrated solution for aerospace surface finishing. Partner with Valence and elevate the performance and reliability of your aerospace components. |

The Importance of Metal Plating

Metal plating is vital for enhancing the safety, reliability, and longevity of components in aerospace and industrial applications. Key benefits include:

- Corrosion Resistance: Shields parts from harsh environments, including humidity, salt exposure, and chemical damage.

- Wear Resistance: Increases the durability of components exposed to friction and mechanical stress.

- Electrical Conductivity: Improves performance in sensitive electrical and electronic systems.

- Thermal Management: Enhances heat dissipation in high-temperature applications.

At Valence Surface Technologies, we ensure your components are engineered for superior performance in even the most demanding conditions.

Aerospace Metal Plating Applications

Metal plating plays a critical role in ensuring the durability and functionality of components in aerospace and industrial systems. Common applications include:

- Landing Gear Components: Provides corrosion protection and reduces wear for axles, struts, and landing gear assemblies.

- Hydraulic Systems: Improves durability and reduces friction for rods, cylinders, and seals.

- Engine Components: Protects parts exposed to extreme heat and mechanical stress.

- Structural Components: Extends the lifespan of airframes, fuselages, and support structures.

- Fasteners & Connectors: Ensures reliability and conductivity in mission-critical systems.

Contact Valence Surface Technologies in Massachusetts

For businesses in Massachusetts seeking industry-leading industrial and aerospace metal plating services, Valence Surface Technologies is your trusted partner. With advanced technology, unmatched expertise, and a focus on quality, we deliver surface finishing solutions that exceed expectations.

Contact us today to learn more about our metal plating services or to discuss your specific project requirements.

Frequently Asked Questions About Industrial & Aerospace Metal Plating in Massachusetts

What metals do you offer for plating?

We offer cadmium, chrome, nickel, and copper plating to meet the diverse needs of aerospace and industrial applications.

How does metal plating improve component performance?

Metal plating enhances corrosion resistance, wear protection, conductivity, and thermal management, ensuring components perform reliably in challenging conditions.

What types of coatings do you offer for aerospace components?

We offer a wide range of coatings, including nickel plating, chrome plating, anodizing (SAA, hardcoat, and chromic acid), chemical film coatings, and high-performance paints and coatings.

Does Valence offer customized metal plating solutions?

Yes, our team specializes in providing tailored metal plating services to address your unique application requirements.

Can Valence handle large-scale finishing projects?

Absolutely, Valence has the capacity and expertise to handle projects of all sizes, from small components to large-scale aerospace structures.

How can I get a quote for metal plating in Massachusetts?

Reach out to Valence Surface Technologies via our website or phone. Our team will evaluate your project needs and provide a detailed, competitive quote.

Is Valence certified in the aerospace industry?

Yes, Valence Springfield holds various certifications and approvals from aerospace industry authorities, demonstrating our commitment to quality and compliance.