One method for shielding aerospace metals from these damaging elements is plating, which lengthens their lifespan and lowers the possibility of failure while in use.

We will talk about aerospace plating, its significance, and the advantages of an aerospace finish in this article.

What Is Aerospace Plating?

We’ll focus on titanium because it’s so prevalent in the aerospace industry, despite the fact that there are many different metal types that can be electroplated.

Due to the quick and vigorous formation of an oxide coating, titanium is a difficult metal to plate. The development of the plating-nickel titanium method was required because few other metals can bond with a titanium substrate.

If there is a nickel coating underneath the component, it is easier to weld other metals to it. Modern businesses have been attempting to optimize this process due to the increased use of titanium.

- High Phosphorus – Offers superior corrosion protection and improved resilience in extremely acidic situations.

- Medium Phosphorus – A good choice for enhancing the substrate’s aesthetic appeal.

- Low Phosphorus – Known to provide the best resistance to alkaline conditions and boost surface hardness and solderability.

Recently developed black electroless nickel coating makes it easier to absorb light and energy. This offers a more practical option for enduring harsh environments and circumstances while adding aesthetic applications when a black finish is required.

What Is The Difference Between Coating And Plating?

Below we’ve provided a better understanding of the difference between coating and plating.

What Is Plating?

Plating is a surface covering in which a metal is deposited on a conductive surface. For instance, gold or silver plating is frequently used on brass and woodwind instruments. Electroplating and electroless plating are used to create the finish. While electroless plating uses autocatalytic chemicals, electroplating needs an electric current.

Surface Finish is the process of removing a layer of metal to improve the appearance and/or functionality of the metal by limiting or adding peaks/valleys to create or limit a surface texture. Here are a few examples of common surface finish procedures

What Is Coating?

A coating protects an object’s surface. The term “substrate” generally refers to the object that is being coated. Coating is important for both functional and decorative purposes. Paints and lacquers, for instance, serve both decorative and protective purposes when applied to a substrate’s surface.

Adhesion, wettability, corrosion resistance, wear resistance, and other qualities are among the functional characteristics of coatings. A coating may cover the entire object or just a portion of it.

Benefits Of Plating

The benefits of plating can be seen as follows with:

Plating Adds Properties To Metals

Different electrolyte types, including those based on copper, nickel, silver, and gold, are available from precision plating. Metal is made more appealing by electroplating because it is utilized in so many different industries.

In order to make used automotive components like bumpers, tire rims, and grills look brand-new, electroplating is frequently used.

Because of its superior conductivity, silver electroplating is frequently used on brass and copper connectors. Switchgear in the telecommunications sector is plated with palladium and gold.

Plating Enhances Appearances

Usually, a thin layer of precious metal is applied to jewelry to give it a more lustrous finish. Manufacturers use plating as a productive and economical way to improve the aesthetic appeal of their products. Jewelers can now offer cheaper jewelry that imitates precious metals like pure gold.

When exposed to acidic sweat, silver jewelry is prone to tarnishing; electroplating can delay this process. Additionally, it lessens scratches and abrasion. As a result, silver goods can maintain their appeal and value over time.

Improves Quality of the Manufacturing Processes

Important advantages and features of electroplating can raise the caliber of manufacturing processes. You’ll be able to advance your position in the industry.

The following are a few advantages of electroplating for manufacturing processes:

Reduces Friction: Nickel plating can help to lessen friction buildup. Electrical connectors are one instance. Nickel plating prevents premature deterioration. Additionally, it raises efficiency.

Conducts Electricity: When making electrical components, silver plating improves electrical conductivity. It is a conductivity solution that is both effective and affordable.

Absorbs Excess Hydrogen: During the manufacture of automotive catalytic converters, palladium plating can absorb extra oxygen. Performance of the catalytic converter is enhanced by the process.

Increases Hardness: Electroplating increases the tensile strength of brittle materials. Surfaces that have been plated will probably withstand damage from dropping or striking.

Benefits Of Coating

The benefits of coating are as follows:

Coating Prevents Rust and Corrosion & Improves Product Aesthetics

Parts or components that have been coated have rust and corrosion resistance, shielding them from contaminants and chemicals. It increases a product’s lifespan in terms of both functionality and appearance. Additionally, it lessens product contamination, which the food industry demands.

A sleek finish is also produced by coating while the product’s integrity is preserved. Control levers, pallet jack handles, and guardrails are just a few examples of the various applications that coating’s rust and corrosion resistance properties can benefit from.

Abrasion-Resistance Coatings Add Durability

Coatings that are resistant to abrasion increase durability and stop component wear. Components are shielded from damaging substances so they can perform as expected. The use of coating in loading chutes for potash is one example.

Additionally, coating encourages chemical resistance, preventing contamination and corrosion as well as keeping various materials from adhering. Racks for part processing, electrical insulation, containers, valves, tanks, pipers, and mixers are all excellent candidates for coating.

Used To Make Non-Stick Products

The food industry is the main user of non-stick products. Applications with low to high releases are available. A smooth surface gets a quick release thanks to high-release coating.

Low-release, on the other hand, is used on a matte surface. Coating lowers scrap, improves manufacture, and extends product productivity and life.

Keeps Low Friction To Keep Surfaces Lubricated

Utilize coating to stop wear and ensure durability because it encourages low friction.

To maintain low friction, avoid seizing, and lower maintenance costs, coating is used. Product chutes, control valve assemblies, and actuator screws are just a few of the varied applications.

Used For Electrical Insulation

The parts are protected from electrical currents by coating. It stops materials from sticking and static buildup, especially on the substrate. Coating is used on beverage filling probes, printing equipment, and copy rollers because of this.

Difference Between Plating And Coating

The primary distinction between the two is that while plating fuses the new material to the original material the fastener is made from, coating merely adds a powder or chemical layer to the surface of a fastener.

The electroplating procedure can produce a more uniform thickness because it is more controllable.

Why Is Aerospace Plating Important?

Increased Resistance

When metals are overlaid with a protective metal plate, the longevity of the product increases. Without treatment, the metal can wear and disintegrate. Metal plating proves better durability and resistance to abrasion and protects the metal from corrosion, chemical damage, and wear. This is important for machine tools, dies, and drills which are often coated in PVD.

Higher Electrical Conductivity

The highest level of electrical conductivity is possible to maintain. Their conductivity may ultimately be impacted by issues like corrosion and normal wear and tear, which frequently negates their utility and purpose. You can ensure durability and top-notch performance by taking precautions to safeguard the parts of your project that depend on electrical conductivity.

We provide services like precision plating masking, pre-processing treatments, and more because we recognize that each project has specific requirements and guidelines. To give you the best services possible, our experts can assist you in determining precisely what metal finishing you need for your upcoming project.

Extends Parts And Components Lifespan

Due to the numerous advantages that increase the durability of your project, electroplating is a great way to improve protection. External factors that can lead to corrosion and other wear are easier to avoid, which ultimately lowers the cost of replacement in the long run.

Stronger Metal Substrate

Depending on the substrate chosen, electroplating can increase the strength of your product significantly. Though every finish can create different results, some of the most common are increased hardness, corrosion resistance, heat resistance, and abrasion prevention.

We offer a number of plating processes and are welcome to the idea of researching new materials to use in the future for our customers’ needs.

Adds Aesthetic Appeal

When the original metal is polished and plated, it looks better. The polishing procedure cleans and smooths the metal product’s surface while removing any flaws, pits, scratches, and sharp edges. The product can also have decorative accents like color application and can be further processed to a matte, glossy, or textured/brushed finish. For mirror-like results, an electroplate is applied over a polished surface to further reduce surface roughness.

While protecting the surfaces from corrosion, electroplating over matte and brushed finishes will preserve the texture characteristics of the surface. When you consider that the benefits are expected to last for generations, the effort is well worth it.

Plating Services

Some plating services to note include:

Cadmium Plating

In the past, cadmium plating was frequently used as an alternative to zinc on many automotive parts. It was specified by aircraft manufacturers because of its sacrificial protective properties and inherent lubricity for frequently removed and reinstalled components. The fact that it can withstand both freshwater and saltwater makes it especially well-suited to marine environments.

It is still available, but due to safety worries, its use as a plating material has diminished over time. Manufacturers of aircraft are increasingly using zinc-nickel alloy plating.

Chrome Plating

Although chrome plating is frequently only used for aesthetic reasons, it also promotes increased corrosion resistance and hardness, making it ideal for industrial applications where wear is a concern. Hard chrome plating, as it is known in this context, is occasionally used to restore tolerances on worn-out components. In the manufacture of steel furniture, car trim, etc., chromium is most frequently plated over nickel.

There is no anodic activity because nickel is typically plated over copper, and the combination of these three elements simply prevents the underlying metal from corroding by restricting air and moisture. In order to achieve adequate corrosion protection, the platings must be appropriately applied.

Hexavalent chromium, a chromic acid, is most frequently used in the electroplating process known as chrome plating. Another choice for industrial uses is trivalent chromium baths, which are mostly made of chromium sulfate or chromium chloride.

Chromate is occasionally applied on top of zinc plating to protect the zinc and, in some situations, change the color of the metal, as in the case of green or black zinc plating.

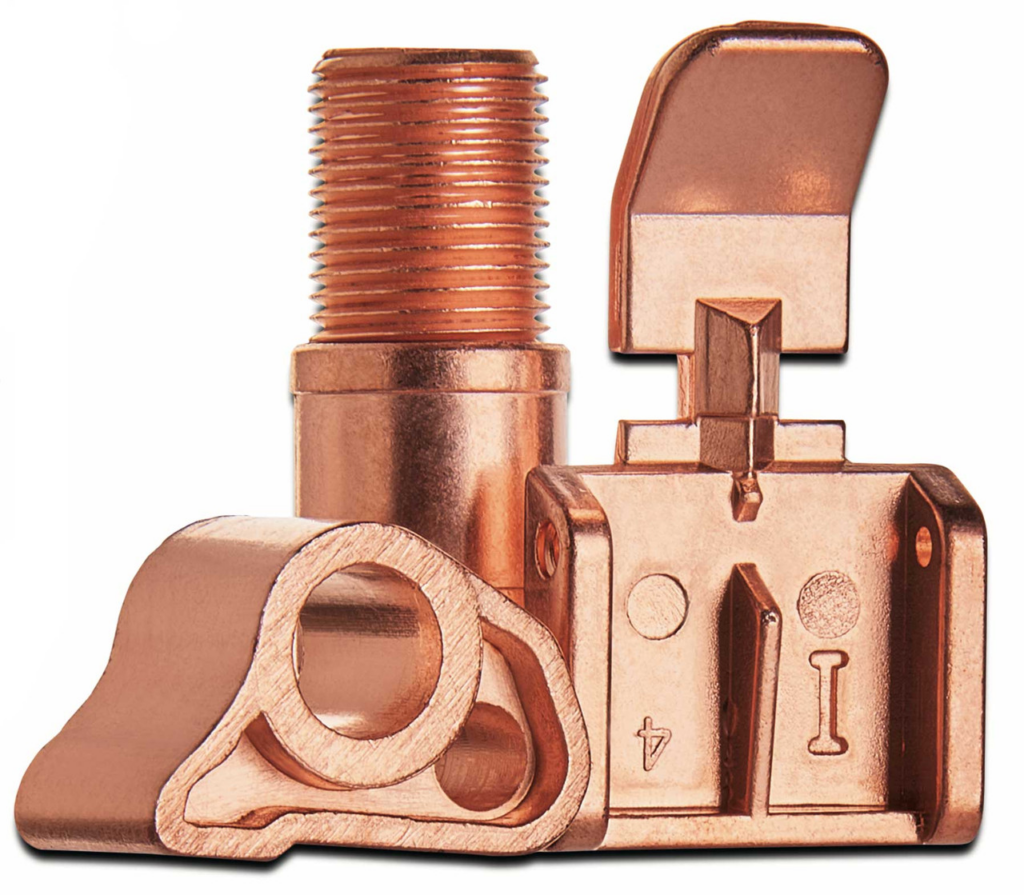

Copper Plating

Another common plating material for uses requiring excellent conductivity and cost-effectiveness is copper. As was mentioned before, copper plating frequently acts as a strike coating pretreatment for subsequent metal platings. Additionally, it is a widely used plating metal for electronic parts like printed circuit boards. Copper is one of the less expensive metals to plate with because of its high plating efficiency and cheap material cost.

There are three different methods for copper plating: acid, mildly alkaline, and alkaline. Superior throwing power is provided by higher alkaline levels, but these values also call for lower current densities and more stringent safety measures. It is crucial to keep an eye on these levels since cyanide in alkaline copper baths has been connected by health inspectors to a number of health risks.

Electroless Nickel Plating

Electroless Nickel Plating is a unique process that uses heat and a unique chemical bath to create the nickel without the use of any electrical current. Since electroless nickel finishing does not use electricity, the coating created by the process is very uniform across the entire surface of the part, even parts with complex geometry. Threads and close tolerance features can be plated precisely without edge build-up.

Gold Plating

Due to its high oxidation resistance and electrical conductivity, gold is highly valued. One of the simplest ways to imbue these qualities on metals like copper and silver is through gold plating, which differs from gilding in that the gold is not a foil.

Jewelry is frequently embellished using this technique, and electrical connectors and other electronic parts can have their conductivity increased.

Applying a nickel strike prior to the gold plating process is the simplest way to prevent tarnishing on copper. Consider the gold’s hardness and purity when deciding on variables like the ideal bath combination and immersion time.

Manganese Phosphate

A conversion coating made of manganese salt, phosphoric acid, and an accelerator is known as a manganese phosphate coating. This high-temperature process results in a surface with good corrosion and wear resistance. Coatings made of manganese phosphate can keep lubricants like oil in place.

Nickel Plating

Nickel is a popular plating metal because it performs well in electroless plating. Household items like doorknobs, silverware and shower fixtures are frequently nickel plated for better ornamentation and wear resistance. Chromium is plated on top of nickel, which frequently forms bonds with copper, aluminum, and a variety of other metals.

In electroless plating, a nickel and phosphorus alloy is used. The solution’s phosphorus content can be anywhere between 2 and 14%. Higher phosphorus concentrations enhance corrosion resistance and hardness. Lower phosphorus levels offer better magnetism and solderability.

Rhodium Plating

A kind of platinum known as rhodium offers resistance to tarnish, and scratching, and a glossy, white dazzling luster. Rhodium plating is frequently used in the manufacture of jewelry, particularly when white gold needs to be plated. Rhodium plating is also common on base metals, including copper, platinum, and silver.

One drawback of rhodium plating is that in applications that experience a lot of wear, the protective layer of rhodium will eventually disappear. After a few years, this can result in discoloration and call for another round of plating.

Silver Plating

Silver is utilized in plating processes, much like gold, when improved electrical conductivity and aesthetic appeal are necessary. Silver generally serves as a more cost-effective plating solution because it is less expensive than gold and does a better job of plating copper.

Two issues that could make silver plating less useful as a plating method are humidity and galvanic corrosion. Silver plating does not work well for applications that are exposed to high humidity because silver is prone to flaking and cracking, which could eventually reveal the base substrate.

Ti-Cad Plating

Ti-Cad, also known as titanium cadmium plating, offers corrosion resistance for applications involving high-strength steel. It greatly lessens the harmful effects of hydrogen embrittlement.

Tin Plating

Food and drink packaging has long been made of tin-plated steel. Tin is toxic-free, offers a coating that makes steel form quickly (due to the lubricity it offers), welds, and solders with ease, in addition to offering corrosion resistance. The tin plate is covered in food-grade oil during the passivation process, which also enhances lacquer adhesion.

To better meet the needs of the interior and exterior container surfaces to their environments, tin plate sheets can be ordered with various tin thicknesses on each face. Other packaging materials, such as paint cans and grease tins, also use a tin plate. The hot-dip method is nearly always used to create the tin plate. Electronic parts are also made with the use of tin plating.

A tin-lead alloy was typically applied over steel in terneplate, another tin-based plating, as a corrosion inhibitor. The metal is perfect for use in tin roofs since it can be painted and, with routine maintenance, last 90 years. Tin is now used over stainless steel instead of lead to create corrosion-resistant roofing that takes on a softer patina. The material has a two-times longer lifespan than copper roofing.

Zinc Plating

As earlier described, zinc plating is one of the most durable metal plating available. Zinc is an inexpensive material that is used to provide a galvanized coating on many metal substrates. In addition to being electroplated, the element is applied by way of the sherardising process, by molten bath dipping, and by spraying.

In the electrolytic or cold process, the article to be plated is set up as a cathode in an electrolytic bath of soluble zinc salts together with an anode of metallic zinc. The process produces a highly ductile coating of pure zinc whose thickness and uniformity can be precisely controlled.

Choosing The Best Aerospace Plating For You

Aerospace has some of the strictest standards for quality, consistency, and validated processes of any industrial sector—and for good reason.

Even the smallest stamped and plated electronics component can and will have an impact on the safety of an aircraft, its occupants, crew, and payload.

Reliability, robustness, and resilience are essential. The most demanding conditions must be overcome by components with plating that is only a few microns thick: friction, atmospheric corrosion, and high temperatures.

In the combustion chamber of a typical commercial jet engine, fuel is burned at up to 2,000°C. Additionally, the air temperature varies from -40°C to -57°C between 30,000ft and 42,000ft, which is the cruising altitude of the majority of airplanes.

The following are questions you should answer when considering an aerospace plating company to work with.

FAQ

Can the plating company meet the varied demands of the aerospace subsectors?

Despite the global accreditation requirements for the aerospace industry, there is no “one size fits all” approach to providing effective solutions to difficult aero-engineering problems.

Specific requirements apply to sub-sectors like general aviation, large civil aircraft, commercial space, unmanned aircraft systems, rotorcraft, airport infrastructure, and aviation security. This necessitates that the stamping/plating company pay close attention to detail.

Additionally, a thorough understanding of the technical issues that could potentially affect linked components and assemblies further up the aerospace supply chain is necessary. Valence Surface Technologies, a highly skilled plating specialist, is frequently contacted by aerospace suppliers to address problems with component electroplating quality and consistency.

Suppliers frequently run into problems because they didn’t ask the right questions or fully comprehend how the technical requirements the aircraft must meet would affect their components and assemblies.

One of the biggest issues is corrosion caused by the environment. The main cause of corrosion in aircraft is a combination of oxygen and water or water vapor containing salt. Aircraft that fly over water and those that fly in areas where there are significant levels of industrial fumes in the air are particularly vulnerable.

Corrosion creates a greenish film on the copper and copper alloys used in avionics systems, compromising connectivity. Thin oxide, sulfide, and inorganic films increase contact resistance by reducing metal-to-metal contact.

To improve the corrosion resistance of components, a layer of metal with very potent anti-oxidation properties must be electroplated. Additionally, it makes those solder joints more reliable and solderable.

Can the plating company meet the added demands of military aerospace?

Demands for military aircraft are significantly higher than those for commercial aircraft. A fighter jet with a Mach 2.8 top speed and a commercial airliner that flies between airports are completely unrelated.

Additionally, in the world of military aviation, a fighter’s requirements are far more stringent than those of a military transport airlift when performing 9G vertical zoom climbs (or a refueling tanker based on a civilian airliner).

Some of the most advanced military aircraft in the world, including those that perform very high-G maneuvers, use electronic connectors stamped and plated by Batten & Allen.

In order to address the issues of conductivity, insulation, hardness, ruggedness, and exposure to chemical/caustic environments, we offer specialized plating solutions. According to the following military plating standards, our products and procedures:

- MIL-P-81728 – tin/lead

- MIL-C-14550 – copper

- MIL-G-45204 – gold

- MIL-C-13924 – black oxide coating.

How experienced is the plating company? And in which metals?

It is critical to select a plating specialist with extensive knowledge of a variety of metals, such as:

Tin-lead: Tin-lead is better for soldering, has excellent conductivity, is relatively corrosion-resistant, and prevents the growth of tin whiskers.

Nickel: offers an exceptional level of adhesion for subsequent plating layers and a special combination of corrosion and wear resistance.

Zinc-Nickel: The corrosion-resistant qualities of nickel are combined with the sacrificial properties of zinc to absorb the worst of the corrosion before it reaches the substrate.

Copper: is malleable, corrosion resistant, and offers superb conductivity

Silver: the highest electrical conductivity, high thermal conductivity, corrosion resistance, and excellent solderability are all attributes of silver.

Gold: Gold resists corrosion and is heat-resistant enough to withstand electrical connections.

Cadmium: Outstanding corrosion resistance is provided by cadmium.

When applying multiple layers of plating, care must be taken to minimize intermetallic problems and increase solderability (and therefore reliability).

When aerospace components are finished with nickel or a nickel alloy, the substrate becomes harder, enhancing wear resistance and corrosion protection.

The thickness of the oxide layer on the substrate’s surface is increased by anodizing. It increases surface abrasion resistance, offers additional corrosion protection, and aids in extending the functional life of components (and enhance their aesthetics).

Final Thoughts: Plating For Your Project

Looking to talk to an expert on aerospace plating or finishing-related topics? Let Valence help you. Valence is the industry leader in quality for precision components in the aerospace, satellite, electronics, and medical device industries. With unique selective plating and precision masking techniques for critical plated components, we are the leader in satellite and UAV applications, including a proprietary process for the precision internal plating of waveguides.

We offer integrated honing and grinding capabilities to complement our cadmium and chrome plating. To get a quote on your next project, get in touch with us today and we’ll discuss all of the surface finishing questions you may have.