The aerospace industry is one of the most advanced and complex industries in the world. It requires high levels of precision and accuracy in order to ensure the safety and reliability of aircrafts and components. As such, precision finishing has become an integral part of the aerospace industry.

Precision finishing is a process used to improve the surface finish of components and reduce their weight. It involves using specialized tools, techniques, and materials to achieve the desired results. This process is essential for enhancing the performance of aerospace components, as well as improving their durability.

In this article, we will discuss the importance of precision finishing and its various benefits to the aerospace industry. We will also discuss the types of precision finishing and answer some frequently asked questions about precision and accuracy in aviation. So, let’s get started!

Don’t compromise on safety and reliability. Let Valence Surface Technologies help you optimize your aerospace components with our precision finishing expertise. Contact us today to learn more!

Precision Finishing: What It Is?

Precision finishing is a process used in the aerospace industry to achieve a smooth, uniform surface finish on components. This process is used to improve the performance of components, reduce weight, and increase durability. Precision finishing is also known as super finishing, micro-finishing, or ultra-precision finishing.

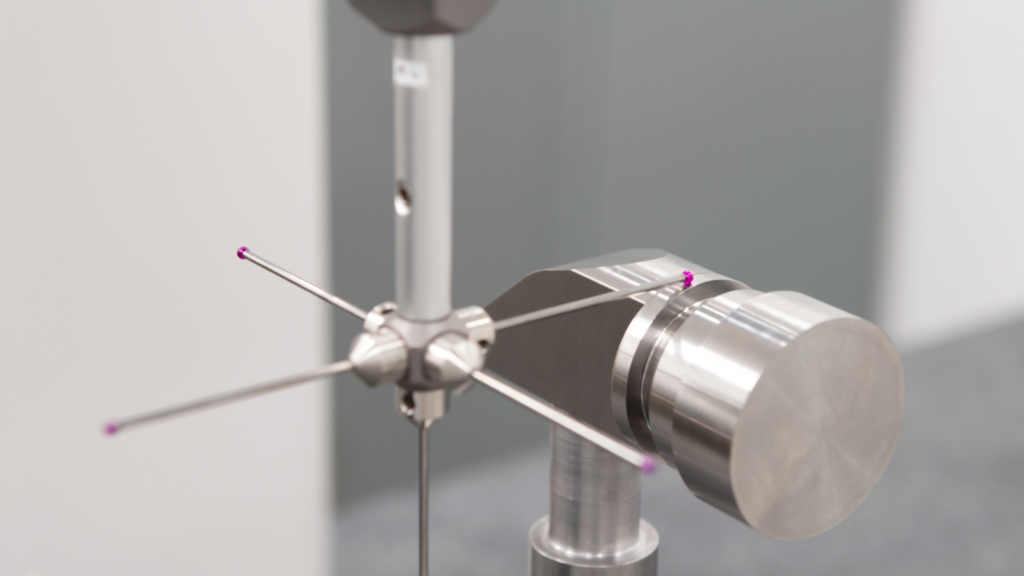

The process of precision finishing involves the use of a variety of tools and techniques to achieve the desired surface finish. These tools can include abrasive belts, honing stones, grinding wheels, and polishing pads.

Abrasive belts are used to remove the surface imperfections on the component.

Honing stones are used to create a smooth, uniform surface.

Grinding wheels are used to refine the surface further and remove any remaining imperfections.

Finally, polishing pads are used to create a smooth, glossy finish.

The process of precision finishing is highly accurate and repeatable, which allows for consistent production of components. It also allows for greater flexibility in design, as components can be produced to exact specifications.

Additionally, the process of precision finishing is much faster than traditional finishing methods, resulting in shorter turnaround times.

Benefits Of Precision Finishing

Precision finishing offers smoother surface finishes, weight reduction, and improved component durability. The following are detailed benefits of precision finishing.

Production Costs Have Been Significantly Reduced

Precision finishing for aerospace components has been a game-changer for the industry, enabling companies to reduce production costs significantly.

It eliminates the need for manual labor and manual finishing processes, and allows for more precise control over the production process, resulting in fewer defects and improved quality control.

It also reduces the need for expensive raw materials, as the process is more precise and requires less material. All in all, precision finishing has been instrumental in reducing production costs for the aerospace industry.

Production Can Be Repeated Consistently

Precision finishing allows for the production of components that have a consistent and repeatable surface finish. In order to achieve this level of consistency and repeatability, precision finishing processes must be utilized. These processes include grinding, polishing, and honing, which are used to achieve a smooth, uniform surface finish.

Using these processes, components can be produced with a consistent surface finish that meets the aerospace industry’s requirements.

There Is Greater Flexibility In Design

Precision finishing enables greater flexibility in design, allowing aerospace engineers to create components with improved performance characteristics. By using precision finishing techniques, engineers can create lighter, stronger, and more efficient components.

This allows them to withstand higher levels of stress and strain and be more aerodynamic. Additionally, they can create components that are more resistant to wear and tear, increasing their lifespan.

Turnaround Times Are Faster

Precision finishing allows for faster turnaround times, allowing for faster production and delivery of components. This is due to the reduction of time needed to achieve the desired surface finish and finish the finishing process.

The process is more efficient and accurate, resulting in faster turnaround times, and allowing for components to be delivered faster, increasing production and delivery efficiency.

Surface Finishes Are Of The Highest Quality

The highest quality surface finishes are achieved by using the most advanced technology and techniques available. This includes computer-controlled equipment and robotic systems, which allow for greater accuracy and consistency.

Precision finishing also helps reduce components’ weight and improve their durability, creating smoother surfaces that reduce friction and wear.

It also helps to improve the aesthetic of components, as the surface finish can be tailored to the individual customer’s needs, creating a more attractive product that can help to increase customer satisfaction and loyalty.

Types Of Precision Finishing

Types of precision finishing can vary depending on the application and the desired outcome. Generally, precision finishing can be divided into two main categories: abrasive and non-abrasive.

Abrasive Finishing

Abrasive finishing is often used to achieve a smooth, polished surface. This type of finishing can be used to remove burrs, scratches, corrosion, and other surface imperfections.

It can also be used to create a uniform surface finish or to prepare a surface for painting or other treatments. Abrasive finishing can be performed manually or with automated machinery, depending on the size and complexity of the part.

Non – Abrasive Finishing

Non-abrasive finishing is typically used to create a highly polished surface. These processes involve using chemicals or electrochemical processes to remove metal or plastic from the part’s surface.

This type of finishing is often used to improve a part’s appearance or create a highly polished surface. It can also be used to improve the performance of a part by reducing friction and wear.

No matter the type of precision finishing used, it is important to ensure that the process is done correctly. Improperly finished parts can lead to decreased performance and even failure. It is important to work with an experienced precision finishing professional to achieve the desired results.

The Role Of Precision Finishing In Enhancing Aerospace Component Performance

The aerospace industry is constantly striving to improve the performance of its components. Precision finishing is one of the most important tools in achieving this goal.

Precision finishing is a process of achieving a smooth surface finish on components to ensure they meet the highest levels of quality and performance. This process is used to improve the durability and reliability of components, as well as reduce the weight of the components.

In the aerospace industry, precision finishing is used to improve the performance of components by reducing friction, improving aerodynamic performance, and increasing the life of the components. The aircraft can move more efficiently and with less drag by reducing the friction between components.

This reduces fuel consumption and increases the range of the aircraft. Additionally, the smoother surface finish reduces wear and tear on the components, increasing their life. Finally, the reduced weight of the components can result in improved performance, as lighter components can move faster and farther.

To achieve the highest levels of precision and accuracy, aerospace components must be subjected to various processes including grinding, polishing, and deburring. These processes remove any imperfections from the surface of the component, resulting in a smooth, uniform finish. This smooth finish helps reduce friction, improve aerodynamics, and increase the component’s life.

How Valence Surface Technologies Can Help?

Valence Surface Technologies is a leading provider of precision finishing services for the aerospace industry. Our advanced technology and processes allow us to deliver superior results in terms of accuracy, repeatability, and surface finish quality.

Our precision finishing services can help aerospace companies reduce production costs, improve production consistency, and increase the performance of their components.

We are a full-service surface finishing company specializing in the commercial aerospace, defense, space and satellite industries. With ten strategically located sites across the United States, Valence provides a start to finish solution from NDT and chemical processing, to paint and sub-assembly.

Are you looking for a world class partner on your next metal finishing project? You’re in luck today. Feel free to request a quote or contact us with any question that you might have and we’d be glad to provide answers.

For additional topics of interest, check out:

- Top Surface Finishing Applications In Aerospace

- Aviation Metal Finishing

- Electropolishing For Aerospace: What Is It, And How Does It Work?

FAQs

What is precision and accuracy in aviation?

Precision and accuracy are two important concepts in aviation. Precision refers to the ability to repeat a measurement or action with consistent results. Accuracy is the degree to which a measurement or action is correct. Precision and accuracy are essential for safety, performance, and efficiency in aviation.

Why is precision more important than accuracy?

Precision is more important than accuracy in aviation because it ensures that the aircraft can perform consistently and reliably. Aircraft must be able to perform the same maneuvers and tasks with the same level of precision each and every time. If the aircraft is not performing with the same level of precision, it can lead to dangerous situations.

Why accuracy and precision are important in engineering and architecture?

Accuracy and precision are essential for engineering and architecture because the structures and components must be able to perform consistently and reliably. If the engineering and architecture are not performing with the same level of accuracy and precision each time, it can lead to dangerous situations.

Accuracy and precision also ensure that the structures and components are able to perform their intended functions with minimal risk of failure.