Aerospace Anodizing In Orange County

At Valence Surface Technologies, we provide certified aerospace anodizing services in Orange County that meet the most demanding performance, durability, and compliance standards. Our advanced capabilities serve the region’s top aerospace, defense, and commercial manufacturers, offering precise, high-quality finishes designed to extend component life and ensure mission-critical reliability.

Employees

Square Footage

Processes

Processes

Parts Per Year

Processing Capabilities

NDT

Hardness/Conductivity

Magnetic Particle

Penetrant

Painting / Coatings

Dry Lube

Fuel Tank Coating

Primer

Topcoat

Sol Gel

Additional Services

Part Mark

Shot Peen

Chemical Processing Aluminum

Anodize Phosphoric (PAA)

Anodize – Type I Chromic

Anodize – Type II Sulfuric

Chemical Film – Type 1 (Chromicoat L25)

Chemical Film – Type 1 (Alodine 1132)

Chemical Film – Type 2 (Chemeon TCPHF)

Chemical Processing Hard Metals

Passivation Type VI

Titanium Etch (Pickle)

Customer Portal

Valence News

Corrosion Vs Oxidation: Key Differences In Metal Degradation And Protection Techniques

Corrosion vs oxidation—learn the key differences, effects on metals, and best protection techniques. Get expert insights from Valence today!

Tinned Copper Vs Bare Copper: Which Is Better For Electrical Applications?

Tinned copper vs bare copper—Valence breaks down the pros, cons, and best uses for each. Learn which is right for your electrical applications today!

Is Anodized Aluminum Safe? Exploring Its Uses And Benefits In High-Performance Industries

Is anodized aluminum safe? Learn about its uses and benefits in high-performance industries. Understand its safety and applications.

Does Nickel Rust? Understanding Nickel’s Resistance To Corrosion In Aerospace Applications

Does nickel rust? Learn how nickel resists corrosion in aerospace applications. Valence breaks it down—read now for key insights!

What Is Aerospace Anodizing?

Aerospace anodizing is a specialized electrochemical process that enhances aluminum components’ surface properties in aircraft, spacecraft, and defense systems. Through this process, a durable oxide layer is formed on the metal’s surface, which significantly improves corrosion resistance, wear characteristics, and adhesion properties for subsequent coatings or paints.

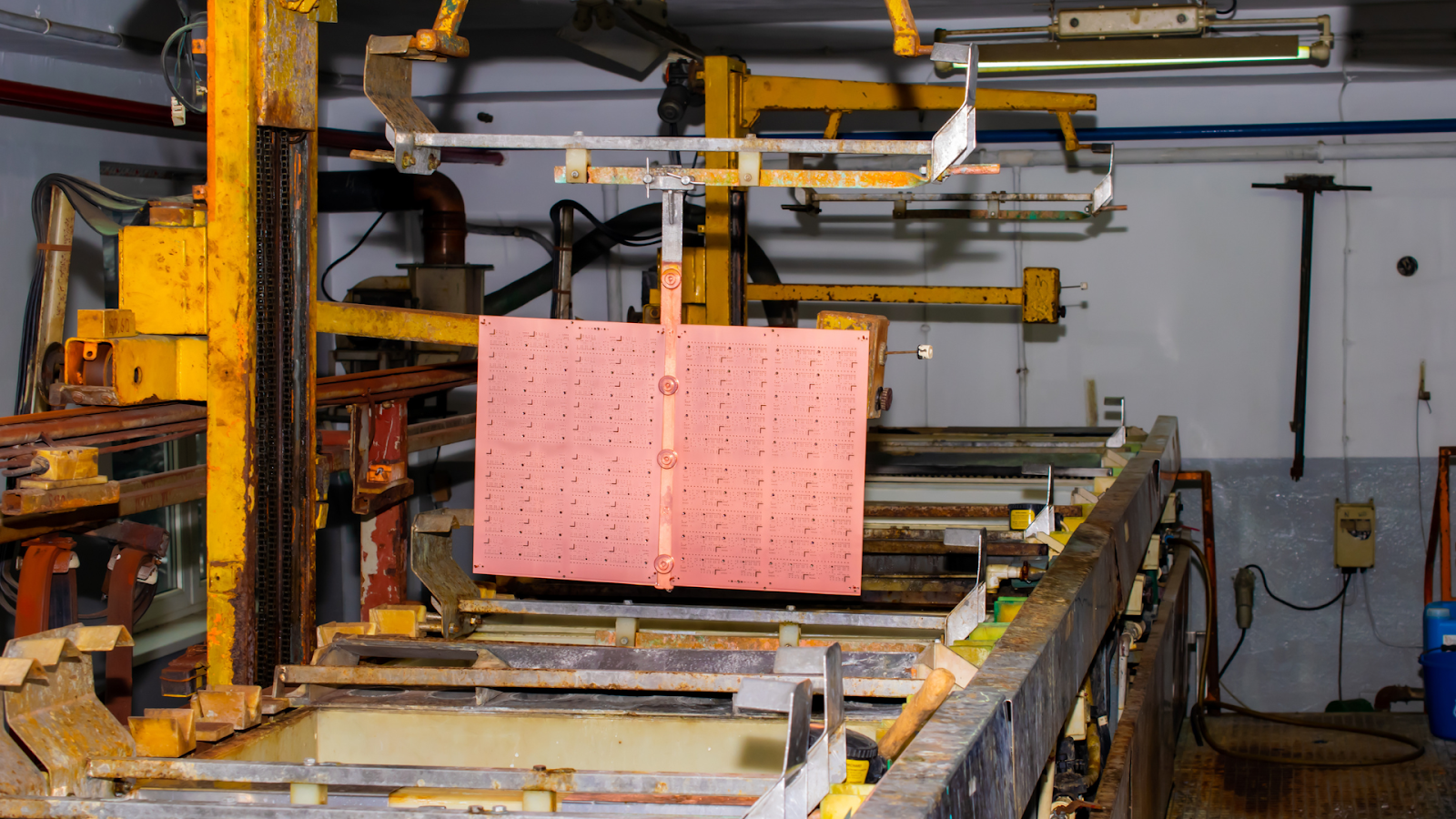

Anodizing in the aerospace sector must adhere to strict industry specifications to ensure reliability and performance. The process typically involves immersing aluminum parts in an acid electrolyte bath and passing an electric current through the solution. This controlled oxidation produces a uniform, high-performance finish that maintains tight dimensional tolerances, critical for aerospace applications where precision is non-negotiable.

Why Choose Valence For Aerospace Anodizing In Orange County

Selecting the right partner for anodizing in Orange County can be a decisive factor in achieving superior performance, reliability, and compliance in aerospace manufacturing. Here’s how our approach supports the most demanding programs in aerospace and defense:

Integrated Solutions For Complex Supply Chains

At Valence, we offer more than just anodizing—we deliver a fully integrated finishing solution. With in-house capabilities including non-destructive testing, heat treating, plating, and painting, we reduce lead times, consolidate logistics, and maintain a single quality system across all operations. This helps our aerospace customers streamline production without compromising precision.

Expertise In Aerospace Specifications

We understand that aerospace finishing is governed by some of the industry’s most rigorous standards. Valence is NADCAP-accredited, AS9100-certified, and compliant with OEM-specific specifications. Our quality and compliance teams ensure that every component meets the durability, traceability, and performance requirements critical to mission success.

Scalable Capacity, Consistent Quality

Whether you’re producing a prototype or managing high-volume programs, Valence delivers unmatched consistency. Our automated processing lines and advanced process controls ensure repeatable, high-quality anodizing across every run, supporting both rapid development cycles and full-rate production.

Advanced Technologies And Proprietary Methods

Innovation is embedded in our approach. Valence continually invests in state-of-the-art anodizing equipment and proprietary surface treatment techniques to serve the next generation of aerospace materials and designs. From fatigue-resistant coatings to finishes that perform in extreme environments, we provide tailored solutions that help our clients stay ahead.

Comprehensive Aerospace Anodizing Services

Valence Surface Technologies offers a full suite of aerospace anodizing services tailored to the industry’s precise needs. Each process is executed precisely to enhance performance, ensure durability, and meet stringent aerospace standards.

Type I – Chromic Acid Anodizing

- Application: Ideal for thin coatings where minimal surface impact is required.

- Benefits:

- Excellent corrosion resistance.

- Superior adhesion for primers and paint.

- Minimal dimensional change, perfect for tight tolerances.

- Common Uses: Aircraft skins, structural components, and assemblies.

Type II – Sulfuric Acid Anodizing

- Application: The most versatile anodizing method, offering durability and customization.

- Benefits:

- Customizable finishes with optional coloring.

- Excellent corrosion protection.

- Balanced wear resistance for functional and decorative parts.

- Common Uses: Fasteners, interior components, and parts requiring aesthetic finishes.

Type III – Hard Coat Anodizing

- Application: Designed for parts exposed to extreme wear and demanding conditions.

- Benefits:

- Thick, highly durable coating for abrasion and impact resistance.

- Exceptional thermal insulation and corrosion resistance.

- Enhanced lifespan for critical components.

- Common Uses: Hydraulic cylinders, landing gear, and engine components.

Other Finishing Services We Provide

At Valence Surface Technologies, our anodizing services in Orange County are only one part of a full suite of aerospace-approved surface treatments engineered for high-performance applications. From corrosion resistance to aesthetic and structural integrity, our finishing capabilities meet the highest technical demands of aerospace, defense, and advanced manufacturing sectors.

Chemical Conversion Coating

We offer chemical conversion coating services that enhance corrosion resistance and paint adhesion on aluminum components. Both chromate and non-chromate options are available, supporting applications that require conductivity, uniformity, and compliance with aerospace OEM and military specifications.

Passivation

Passivation is essential for maintaining the corrosion resistance of stainless steel aerospace components. Our controlled process removes free iron and promotes the formation of a passive oxide layer, which is critical for preventing premature failure in extreme flight or environmental conditions.

Plating And Electroplating

From nickel plating to cadmium and other aerospace-approved metals, our electroplating services meet the strictest industry certifications. These coatings offer enhanced wear resistance, electrical conductivity, and corrosion protection—all delivered with tight process control and documented quality assurance.

Non-Destructive Testing (NDT)

Our NDT services in California include fluorescent penetrant inspection (FPI) and magnetic particle inspection (MPI), enabling flaw detection at the surface and subsurface levels. These inspections are critical for certifying the integrity of flight-critical hardware without compromising component structure.

Aircraft Painting

Our California-based aircraft painting services offer specialized aerospace coatings that provide thermal protection, chemical resistance, and low-drag finishes. Combined with our masking and preparation processes, we ensure precise coating application for functional and visual performance.

Who We Serve

Aerospace anodizing is a critical process for ensuring the durability, performance, and compliance of metal components used in mission-critical applications. In Orange County, our advanced anodizing capabilities at Valence serve a wide range of organizations that operate in demanding environments and require consistently high-quality finishes.

Aviation Manufacturers

Commercial and private aircraft manufacturers benefit from anodizing processes that enhance corrosion resistance and extend component life. Our solutions support tight tolerances, superior adhesion, and meet industry certifications essential to the aerospace supply chain.

Defense Contractors

Military hardware demands rugged finishes that can withstand harsh operational conditions. Our anodizing services ensure compliance with MIL-SPEC and other defense-grade requirements, delivering protection, electrical insulation, and structural integrity for tactical components.

Space Exploration Organizations

Anodized components are vital in space applications where resistance to radiation, vacuum, and thermal extremes is non-negotiable. We support satellite and launch vehicle manufacturers with high-reliability anodizing that protects sensitive surfaces and maintains performance beyond Earth’s atmosphere.

Benefits Of Aerospace Anodizing

Aerospace anodizing is a critical process in manufacturing aircraft and spacecraft components. This electrochemical process converts the metal surface into a durable, corrosion-resistant, and aesthetically pleasing finish.

Key Benefits Of Aerospace Anodizing:

- Corrosion Resistance: Protects aluminum components from harsh environmental conditions, including salt spray, humidity, and extreme temperature fluctuations.

- Wear Resistance: Enhances components’ surface hardness and durability, reducing wear and tear.

- Improved Adhesion: Provides a superior bonding surface for paints and coatings, ensuring long-lasting protection.

- Electrical Insulation: Offers excellent electrical insulation properties, which are crucial for sensitive electronic components.

- Enhanced Appearance: Provides a range of decorative finishes, from natural aluminum to vibrant colors.

Aerospace Anodizing Applications

Aerospace anodizing is a critical process in manufacturing aircraft and spacecraft components. This electrochemical process converts the metal surface into a durable, corrosion-resistant, and aesthetically pleasing finish. Key Applications of Aerospace Anodizing:

Aircraft Structures

- Fuselage: Anodized aluminum provides lightweight, strong, and corrosion-resistant structural components.

- Wings: Anodizing protects wing structures from environmental factors and improves their fatigue life.

- Landing Gear: Anodized components enhance the durability and corrosion resistance of landing gear, ensuring safe and reliable operation.

Engine Components

- Engine Housings: Anodized housings protect critical engine components from high temperatures, corrosive gases, and mechanical stress.

- Fan Blades: Anodized fan blades improve their wear and corrosion resistance, enhancing engine performance and efficiency.

Electronic Enclosures

- Avionics Enclosures: Anodized aluminum enclosures protect sensitive electronic components from electromagnetic interference, thermal stress, and environmental factors.

- Control Panels: Anodized control panels provide a durable, corrosion-resistant, and aesthetically pleasing surface.

Other Applications

- Fasteners: Anodized fasteners offer excellent corrosion resistance and improved thread engagement.

- Hardware: Anodized hardware, such as brackets and fittings, provides long-lasting performance in harsh environments.

Pricing Information For Aerospace Anodizing In Orange County

Several factors influence the cost of aerospace anodizing in Orange County, especially for companies seeking high-performance finishing that meets stringent industry standards:

- Component Size and Complexity: Larger parts or those with intricate geometries typically require more time, materials, and specialized fixturing.

- Surface Preparation: Parts that need extensive cleaning, etching, or masking may add to the overall cost due to additional labor and chemicals.

- Anodizing Type: Advanced processes like Type III (hardcoat anodizing) involve higher voltages, tighter tolerances, and more rigorous control, impacting pricing.

- Coloring and Sealing: Optional steps such as dyeing for aesthetics or sealing for durability can influence the final price.

- Production Volume: Larger batches can reduce the cost per unit through improved efficiency and process consolidation.

Competitive Pricing From Valence Surface Technologies

At Valence Surface Technologies, we deliver high-precision aerospace anodizing in Orange County, focusing on value, reliability, and compliance. Our advanced technology, automated lines, and process expertise help streamline operations and control costs, without compromising aerospace-grade quality.

Get A Custom Quote

Contact our team directly for accurate pricing tailored to your anodizing project in Orange County. We’ll evaluate your component specs, volume, and finishing requirements to provide a quote that reflects performance and value.

Exploring Valence Surface Technologies’ Locations

Valence Surface Technologies is proud to offer a network of facilities strategically located across the United States to provide aerospace and defense industries with top-quality surface treatment services. Here’s a closer look at the regions we serve and the specialized services we offer at each of our locations:

Eastern Region

Valence Surface Technologies operates multiple facilities in the Eastern U.S. that service the aerospace and defense markets. With locations in Eastman, Georgia, Grove, Oklahoma, Blairsville, Pennsylvania, West Springfield, MA, and Wichita, Kansas, we provide a comprehensive set of surface treatment services.

Our services in this region include:

- Nondestructive Testing (NDT): Advanced methods for detecting material defects, ensuring the integrity of parts before they are put into operation.

- Anodizing: Essential for providing corrosion resistance and aesthetic finishes, particularly for aluminum parts.

- Paint/Spray Coatings: Customized coatings that offer protection against environmental factors and improve the visual appearance of components.

- Shot Peening: A process used to enhance the fatigue life of metal parts by creating compressive stress on the surface.

- Bond Primer: Specialized primers that promote better adhesion of topcoats, ensuring long-lasting durability.

From very small components to parts over 20 feet in length, our Eastern Region facilities are equipped to handle a wide range of part sizes and offer the highest quality standards for aerospace and defense applications.

Northwest Region

Valence’s Northwest Region facilities in Seattle, Washington and Everett, Washington serve the aerospace and defense markets from British Columbia, Canada to Oregon. These locations are strategically positioned to service both the Pacific Northwest and Western Canada, providing full-service aerospace treatments with advanced capabilities.

Our services in this region include:

- Nondestructive Testing (NDT): Ensuring that parts are structurally sound and free from defects before they are utilized in mission-critical applications.

- Anodizing: Providing durable finishes that increase the lifespan of components by enhancing corrosion resistance.

- Paint/Spray Coatings: A vital service for aerospace parts requiring weather-resistant and visually appealing finishes.

- Shot Peening: Vital for ensuring the fatigue resistance of high-stress components, such as aircraft fuselages and engines.

- Bond Primer: Applied to ensure superior adhesion of the topcoats, leading to longer-lasting finishes and superior performance.

Our Northwest Region facilities are fully equipped to handle parts ranging from small components to those up to 30 feet in length. This capacity allows us to meet the needs of various clients in the aerospace and defense industries.

Southwest Region

In the Southwest Region, Valence operates a cutting-edge facility in the greater Los Angeles area, covering California, Arizona, Nevada, and Utah. This region is a hub for aerospace and defense, and our facility in Los Angeles is one of the leading providers of surface treatments in the Western United States.

Our services in this region include:

- Nondestructive Testing (NDT): Ensuring that critical aerospace components meet the highest safety and reliability standards.

- Anodizing: Offering protective coatings for aluminum and other metals that are essential for aerospace parts exposed to harsh environments.

- Plating: We provide a range of plating services that offer corrosion resistance, wear resistance, and improved conductivity for aerospace components.

- Paint/Spray Coatings: Ensuring that parts receive the perfect finish to meet both performance and aesthetic requirements.

- Shot Peening: Used to improve the strength of aircraft parts, prolonging their service life and enhancing their reliability.

- Bond Primer: A key service for ensuring the longevity of topcoats and improving paint adhesion.

Our Southwest Region facility can handle parts up to 25 feet in length, giving us the flexibility to treat both large and small components. Whether you need high-end coatings, advanced testing, or specialized surface treatments, our Los Angeles location offers the experience and facilities to meet your needs.

Contact Valence Surface Technologies Today

Contact us today for trusted aerospace anodizing services in Orange County. Our facility delivers industry-certified anodizing solutions tailored to the strict requirements of aerospace, defense, and space applications. With advanced process controls, full regulatory compliance, and a commitment to quality, Valence ensures your components receive the highest level of surface protection and performance.

Frequently Asked Questions About Aerospace Anodizing In Orange County

What is the difference between Type I, II, and III anodizing?

Type I anodizing uses chromic acid and results in a thin, protective oxide layer primarily for corrosion protection. Type II involves sulfuric acid to create a thicker, more durable oxide film and allows for dyeing for identification or cosmetic purposes. Type III, also known as hardcoat anodizing, produces the densest and hardest oxide layer, significantly increasing wear and abrasion resistance, making it ideal for high-friction aerospace applications.

Is there a standard for aerospace anodizing?

Yes, aerospace anodizing is governed by several industry-recognized standards to ensure quality and consistency. Common specifications include MIL-A-8625, ASTM B580, and AMS 2471/2472. These standards define process requirements, testing methods, and quality criteria for each anodizing type, ensuring compliance with rigorous aerospace and defense industry requirements.

What materials can be aerospace anodized?

Aluminum and its alloys are the materials most commonly anodized in aerospace applications due to their favorable chemical properties and structural utility. Some magnesium alloys can also be anodized, but processes and results may vary. Materials like titanium or steel require different surface finishing techniques and are generally not anodized using standard aerospace methods.

How is aerospace anodizing tested for quality?

Quality testing for aerospace anodizing typically includes visual inspections for uniformity, laboratory analysis of the oxide layer’s thickness, and adhesion tests. Additional evaluations may include corrosion resistance tests such as salt spray or humidity exposure, color verification for dyed layers, and hardness tests for Type III coatings. At Valence, rigorous quality checks ensure all components meet or exceed aerospace standards.

What are common defects in aerospace anodizing?

Common anodizing defects include pitting, burning, uneven color, streaking, and poor adhesion. These issues often result from improper surface preparation, incorrect process parameters, or contamination in the anodizing bath. At Valence, our integrated approach minimizes these risks through stringent controls and continuous process monitoring.

How long does aerospace anodizing last?

The durability of aerospace anodizing depends on the application, type of anodizing, and environmental exposure. Under typical aerospace operating conditions, anodizing can protect components for decades. Type III (hardcoat) anodizing offers the longest service life, especially in high-wear or corrosive environments. Regular maintenance and inspection further extend the longevity of anodized surfaces.