Chrome Plating Fort Worth | Valence Surface Tech Aerospace Finishing

Valence Surface Technologies provides aerospace-grade chrome plating services in Fort Worth, built on precision, repeatability, and deep certification coverage. Our fully integrated process, inspection, masking, plating, and post-treatment all under one roof, meets stringent OEM and SAE specifications while reducing lead times and risk.

With large tank capacity, complex masking expertise, and approvals across aerospace and industrial sectors, we provide reliable, compliant finishes for critical components. We keep programs on schedule, from hard chrome to corrosion-resistant coatings, without compromising detail or quality.

Valence News

Corrosion Vs Oxidation: Key Differences In Metal Degradation And Protection Techniques

Corrosion vs oxidation—learn the key differences, effects on metals, and best protection techniques. Get expert insights from Valence today!

Tinned Copper Vs Bare Copper: Which Is Better For Electrical Applications?

Tinned copper vs bare copper—Valence breaks down the pros, cons, and best uses for each. Learn which is right for your electrical applications today!

Is Anodized Aluminum Safe? Exploring Its Uses And Benefits In High-Performance Industries

Is anodized aluminum safe? Learn about its uses and benefits in high-performance industries. Understand its safety and applications.

Does Nickel Rust? Understanding Nickel’s Resistance To Corrosion In Aerospace Applications

Does nickel rust? Learn how nickel resists corrosion in aerospace applications. Valence breaks it down—read now for key insights!

What Is Chrome Plating?

Chrome plating is a metal finishing process that applies a thin layer of chromium to a component’s surface through electroplating. This enhances its durability, wear resistance, corrosion protection, and aesthetic appeal. In aerospace, defense, and other high-performance industries, chrome plating is often used on landing gear, hydraulic actuators, and precision tooling to maintain tight tolerances and reliable performance under extreme conditions. The coating’s hardness and low friction properties help extend service life while ensuring parts meet strict engineering and compliance standards.

Why Choose Valence For Fort Worth Chrome Plating

At Valence Surface Technologies in Fort Worth, we deliver chrome plating backed by rigorous process control, NADCAP accreditation, and a fully integrated workflow that keeps your parts moving from inspection to final finish without unnecessary handoffs or delays.

Aerospace-Grade Expertise

Valence delivers chrome plating in Fort Worth, backed by decades of aerospace and defense experience. This ensures that every part meets demanding OEM, SAE, and NADCAP standards.

Fully Integrated Processes

Inspection, masking, cleaning, plating, and post-treatment happen under one roof, reducing handoffs, compressing lead times, and maintaining strict process control.

Capacity For Complex Projects

With large tank capabilities, advanced masking, and thousands of approvals, we handle everything from small precision parts to oversized components.

Proven Compliance & Reliability

Our Fort Worth facility produces audit-ready documentation, consistent quality across programs, and reliable throughput for mission-critical applications.

Chrome Plating Techniques And Technologies

Innovation is at the core of our chrome plating capabilities. We use state-of-the-art techniques and precision-driven processes to meet the most demanding aerospace and defense specifications. Our extensive list of industry approvals is proof of our compliance, quality, and technical mastery.

Every project, no matter how complex, receives meticulous attention to detail. From tight dimensional tolerances to flawless finishes, our chrome plating solutions are engineered to deliver unmatched performance, reliability, and consistency across every component.

Commitment To Green Processes

High-performance plating should also protect the planet. That’s why our Fort Worth facility integrates environmentally responsible practices into every stage of production:

- Minimizing waste through advanced bath management and filtration

- Adhering to strict environmental and regulatory standards

- Incorporating eco-conscious technologies without sacrificing quality

Valence leads the way as the aerospace and defense industries move toward sustainable innovation, offering chrome plating solutions that meet performance and environmental goals. This forward-thinking approach positions us as a trusted, future-focused partner in the finishing services industry.

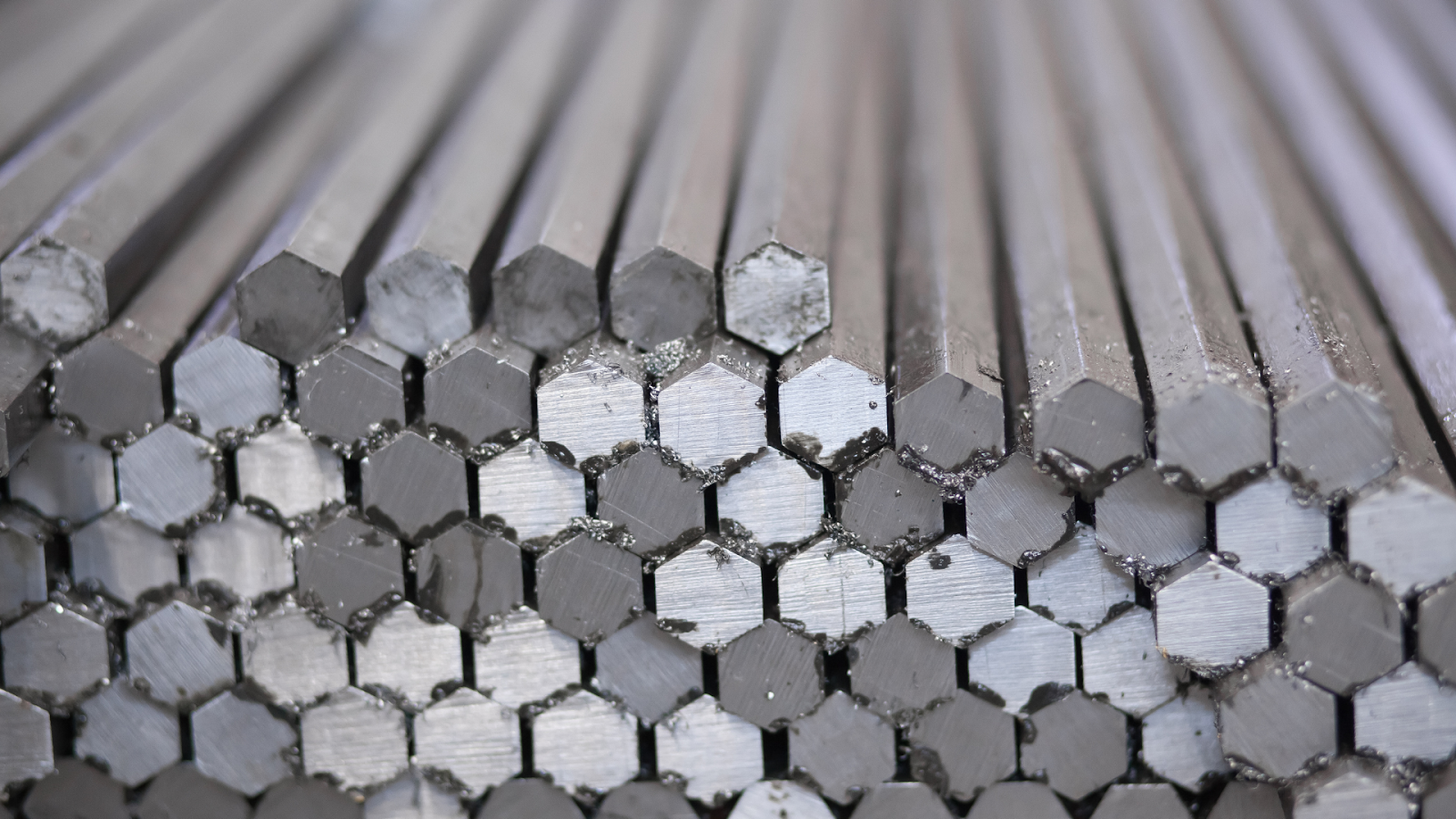

Types Of Metals Suitable For Chrome Plating

Chrome plating can be applied to various metals to improve wear resistance, hardness, corrosion protection, and surface performance.

Common Metals We Plate:

- Steel & Stainless Steel: Ideal for aerospace structures, hydraulic components, and high-strength applications where durability is critical.

- Aluminum Alloys: Lightweight parts needing enhanced wear resistance, corrosion protection, and dimensional stability.

- Copper & Copper Alloys: Frequently used for electrical components and thermal applications where conductivity is essential.

- Nickel Alloys: High-performance materials used in extreme temperature or chemically aggressive environments.

- Brass & Bronze: Specialty aerospace and industrial parts requiring both mechanical resilience and an appealing finish.

Every chrome plating job at Valence is performed under NADCAP-accredited conditions, meeting or exceeding AMS, MIL, and OEM specifications for adhesion, thickness, and performance.

Applications And Industries Utilizing Chrome Plating

Chrome plating is fundamental to high-reliability manufacturing, where durability, wear resistance, and corrosion protection are non-negotiable. Across mission-critical programs, the process ensures dimensional integrity, repeatable performance, and lifecycle value, even under extreme loads and environments.

Aerospace & Defense

Hard chrome extends component life on landing gear, actuators, hydraulic cylinders, and tooling, maintaining tight tolerances and reducing friction under heavy-cycle fatigue, temperature swings, and corrosive atmospheres.

Industrial Manufacturing

Production equipment, rolls, and dies benefit from uniform hardness and improved lubricity, minimizing downtime and scrap while preserving surface finish through repeated thermal and mechanical stress.

Automotive & Heavy Equipment

Engine, drivetrain, and suspension components leverage chrome’s wear resistance and surface stability to sustain high-load, high-speed conditions with consistent performance across long service intervals.

Satellite & Communications

Precision housings, connectors, and waveguide interfaces rely on corrosion-resistant, low-friction surfaces that preserve electrical continuity and mechanical fit through launch shock, vacuum, and thermal cycling.

Medical & Life Sciences

Surgical tooling and precision fixtures use chrome for cleanability, hardness, and dimensional stability, protecting critical surfaces from abrasion, sterilization cycles, and chemical exposure.

Benefits Of Chrome Plating

Chrome plating delivers a durable, high-performance surface engineered for mission-critical environments. Combining exceptional hardness with corrosion resistance reduces maintenance cycles and stabilizes part performance across long duty lifetimes.

- Wear Resistance: Hard chrome’s microstructure resists abrasion and galling, extending component life under high loads, sliding contact, and repetitive stress.

- Corrosion Protection: A dense, adherent deposit acts as a barrier against moisture, chemicals, and fuel byproducts, safeguarding substrates in harsh operating conditions.

- Dimensional Restoration: Precision build-up restores worn or out-of-tolerance surfaces to spec, enabling reuse of high-value parts and tighter stack-up control.

- Reduced Friction: Low coefficient of friction improves efficiency, lowers heat generation, and minimizes stick-slip in actuators, shafts, and bearing interfaces.

- Thermal And Chemical Stability: The coating maintains integrity across wide temperature swings and exposure to aggressive media, preserving surface properties in service.

- Surface Uniformity On Complex Geometries: Controlled deposition and masking strategies achieve consistent thickness on bores, edges, and intricate features without compromising critical dimensions.

- Inspection And Rework Efficiency: Predictable deposit behavior and established NDT compatibility streamline inspection, rework, and traceability within regulated production flows.

Pricing Information For Chrome Plating In Fort Worth

At Valence Surface Technologies, we work closely with customers to align process scope, compliance requirements, and turnaround needs with a cost-effective chrome plating solution. While every project is unique, here are the key factors that typically influence pricing in the Fort Worth region:

Scope Of The Chrome Plating Process

Pricing is determined by the size, complexity, number of parts, and the level of preparation required before plating. More extensive prep, such as stripping old coatings, removing oxidation, or addressing machining marks, can increase labor and processing time. High-volume runs or parts with intricate geometries may require specialized fixturing, masking, and handling, affecting cost.

Volume, Lead Times, And Custom Scheduling

We offer tiered pricing for batch orders and recurring program volumes, often resulting in per-part cost efficiencies for larger runs. Expedited turnarounds, weekend processing, or custom scheduling can be accommodated but may carry premium rates. Providing your production timelines in advance helps us optimize planning, reduce lead times, and offer the most competitive pricing possible.

Exploring Valence Surface Technologies’ Locations

Valence Surface Technologies operates a nationwide network of facilities, strategically positioned to deliver top-quality surface treatments for the aerospace and defense industries. Here’s a snapshot of the regions we serve and key services offered:

Eastern Region

Facilities in Eastman, GA; Grove, OK; Blairsville, PA; West Springfield, MA; and Wichita, KS deliver a full range of treatments, including:

- Nondestructive Testing (NDT) – Detecting material defects before operation.

- Anodizing – Corrosion-resistant finishes for aluminum parts.

- Paint/Spray Coatings – Protective, performance-driven finishes.

- Shot Peening – Enhancing fatigue life with compressive surface stress.

- Bond Primer – Ensuring long-lasting topcoat adhesion.

All facilities are equipped to handle parts from small components to over 20 feet long and meet rigorous aerospace and defense quality standards.

Northwest Region

Located in Seattle and Everett, WA, serving the Pacific Northwest and Western Canada with capabilities including:

- NDT – Ensuring structural integrity of mission-critical parts.

- Anodizing – Extending component lifespan through corrosion resistance.

- Paint/Spray Coatings – Weather-resistant and visually refined finishes.

- Shot Peening – Boosting fatigue resistance for high-stress parts.

- Bond Primer – Maximizing durability of painted finishes.

These facilities can handle parts up to 30 feet and serve various aerospace and defense needs.

Southwest Region

Our Los Angeles, CA facility supports California, Arizona, Nevada, and Utah with services including:

- NDT – Meeting strict aerospace safety and reliability standards.

- Anodizing – Protective coatings for metals in harsh environments.

- Plating – Corrosion, wear resistance, and improved conductivity.

- Paint/Spray Coatings – High-performance and aesthetic finishes.

- Shot Peening – Extending service life of critical aircraft parts.

- Bond Primer – Strengthening topcoat adhesion.

With a capacity for parts up to 25 feet long, we offer advanced coatings, testing, and surface treatments for projects of all sizes.

Contact Valence Surface Technologies Today

Valence Surface Technologies delivers when your program requires certified chrome plating in Fort Worth with aerospace-grade precision, speed, and fully traceable compliance. We align our processes to your exact specification package, validate conformity, and ensure repeatable results across platforms, production volumes, and critical timelines.

- Request A Technical Review: Provide us with your drawings, datums, and target specs. Our team evaluates geometry, masking requirements, bath compatibility, and compliance paths to SAE and OEM standards, then issues a clear process plan with an accurate lead-time estimate.

- Get A Fast, Firm Quote: Send us your part counts and production cadence. We respond with a defined scope, pricing, and schedule calculated based on capacity, tank fit, and inspection flow. There is no guesswork and no hidden variables.

- Align On Qualification And Approvals: We identify all required approvals, including unique OEM callouts and customer-specific clauses. Our team coordinates first-article inspections, coupon testing, and complete documentation bundles to ensure production readiness.

- Schedule Production And Logistics: We allocate dedicated line time, sequence pre- and post-treatments, and arrange secure packaging and transit. Your parts move through one integrated workflow, minimizing touchpoints, reducing turnaround, and maintaining the highest quality standards.

Contact our team today to schedule your technical review, request a firm quote, or secure production capacity for your next program.

Frequently Asked Questions About Chrome Plating Fort Worth | Valence Surface Tech Aerospace Finishing

Does Valence’s Fort Worth facility have NADCAP accreditation?

Yes. Our Fort Worth location is NADCAP-accredited for chrome plating and related finishing processes. This ensures all work meets or exceeds the highest aerospace and defense compliance standards, including OEM and SAE specifications.

How does Valence ensure quality and consistency in chrome plating?

Our Fort Worth team uses closed-loop bath chemistry control, statistical process control, and precise current-density modeling to achieve consistent results within microns of target thickness. All plating is backed by audit-ready documentation.

Can Valence handle large aerospace components?

Yes. With large tank capacity and specialized fixturing, our Fort Worth facility can accommodate oversized parts, such as landing gear, flap-track rails, or structural assemblies—without sacrificing precision or finish quality.

What is the lead time for chrome plating in Fort Worth?

Lead times vary depending on part size, complexity, quantity, and current production capacity. Typical timelines range from several days to a few weeks. Expedited scheduling is available for urgent projects, subject to capacity.

Does Valence offer dimensional restoration with chrome plating?

Yes. Our precision build-up chrome plating can restore worn or out-of-tolerance surfaces back to OEM specifications. This is particularly valuable for high-value aerospace and industrial components where replacement is costly or impractical.

Can Valence plate complex geometries?

Yes. We use custom masking, conforming anodes, and simulation-based current distribution planning to achieve even coverage on bores, recesses, edges, and intricate features without burning or starved areas.